OPERATION

Prepare the saw for ripping as discussed on page 27. Set the rip fence to allow approximately a 1/4 in. “finger” to be cut in

the stock. Feed the stock only to the mark previously made

PUSH STICKSat 6 in. Turn the saw Off and allow the blade to completely stop rotating before removing the stock. Reset the rip fence and cut spaced rips into the workpiece to allow approximately 1/4 in. fingers and 1/8 in. spaces between the fingers.

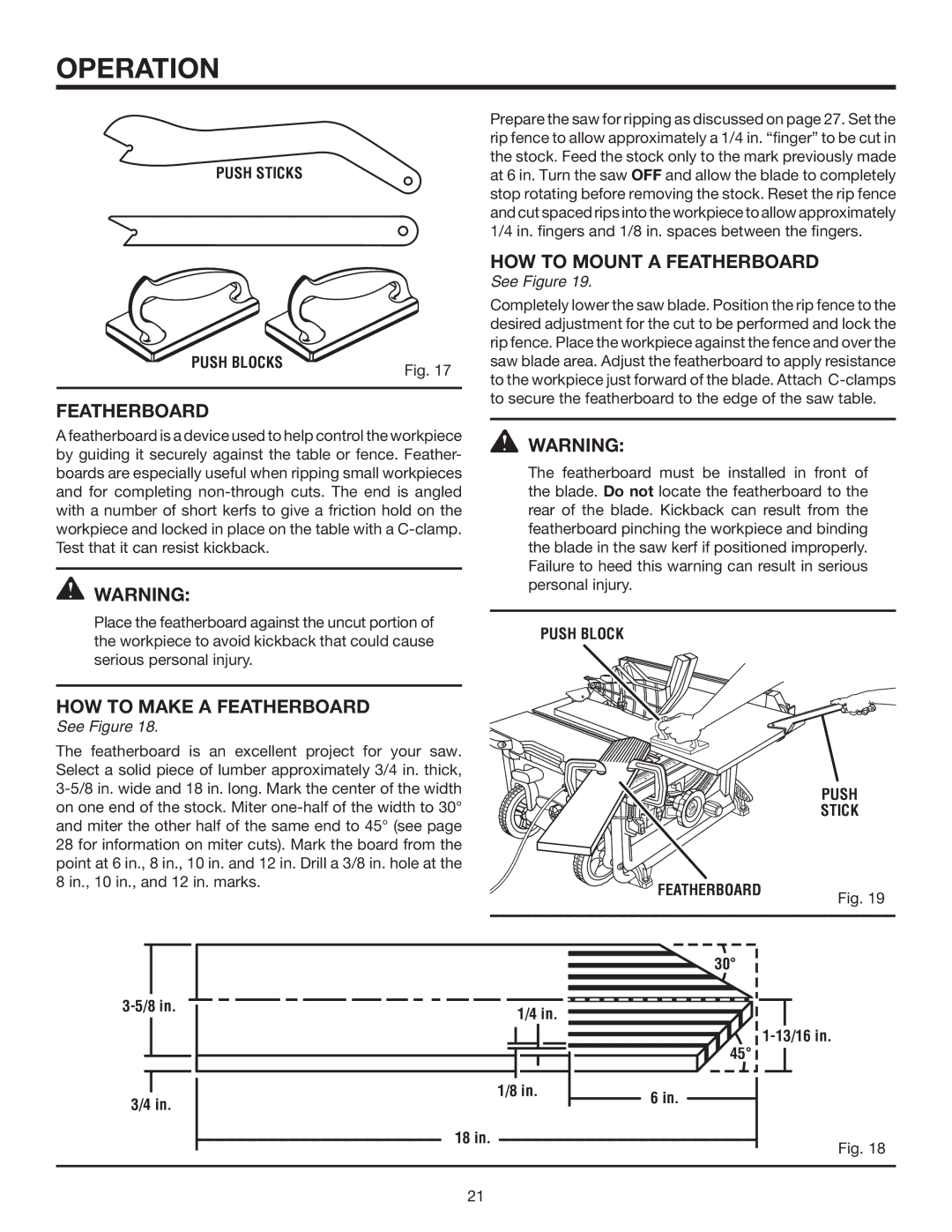

PUSH BLOCKS | Fig. 17 |

|

FEATHERBOARD

A featherboard is a device used to help control the workpiece by guiding it securely against the table or fence. Feather- boards are especially useful when ripping small workpieces and for completing

![]() warning:

warning:

Place the featherboard against the uncut portion of the workpiece to avoid kickback that could cause serious personal injury.

HOW TO MAKE A FEATHERBOARD

See Figure 18.

The featherboard is an excellent project for your saw. Select a solid piece of lumber approximately 3/4 in. thick,

HOW TO MOUNT A FEATHERBOARD

See Figure 19.

Completely lower the saw blade. Position the rip fence to the desired adjustment for the cut to be performed and lock the rip fence. Place the workpiece against the fence and over the saw blade area. Adjust the featherboard to apply resistance to the workpiece just forward of the blade. Attach

![]() warning:

warning:

The featherboard must be installed in front of the blade. Do not locate the featherboard to the rear of the blade. Kickback can result from the featherboard pinching the workpiece and binding the blade in the saw kerf if positioned improperly. Failure to heed this warning can result in serious personal injury.

push block

push stick

featherboard | Fig. 19 |

|

3/4 in.

| 30° |

1/4 in. |

|

| 45° |

1/8 in. | 6 in. |

|

18 in.

1-13/16 in.

Fig. 18

21