Gas Connection

•The gas supply line shall be gas tight, sized and so installed as to provide a supply of a gas sufficient to meet the maximum demand of the heater without loss of pressure.

•A shut off valve and appliance connector valve should be installed in the upstream of the gas line to permit servicing.

•Flexible pipe and any appliance connector valve used for gas piping shall be types approved by nationally recognized agencies.

•Any compound used on the threaded joint of the gas piping shall be a type which resists the action of liquefied petroleum gas (propane / LPG).

•After completion of gas pipe connections all joints including the heater must be checked for gas tightness by means of leak detector solution, soap and water, or an equivalent nonflammable solution, as applicable. (Since some leak test solutions, including soap and water, may cause corrosion or stress cracking, the piping shall be rinsed with water after testing, unless it has been determined that the leak test solution is

•Check the gas supply pressure immediately upstream at a location provided by the gas company. Supplied gas pressure must be within the limits shown in the Specifications section.

•Refer to an approved pipe sizing chart if in doubt about the size of the gas line.

•Install manual gas

Clearances to Combustibles

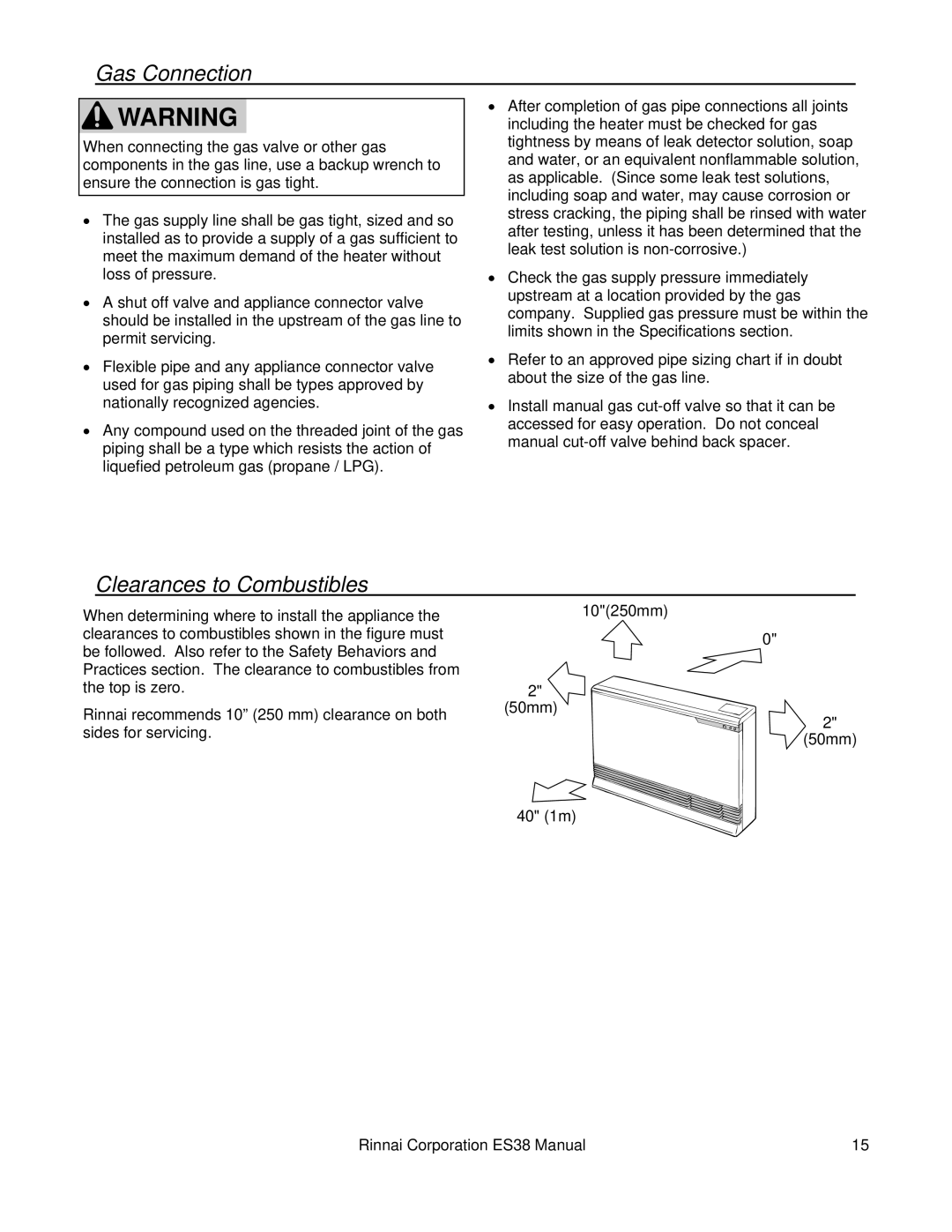

When determining where to install the appliance the clearances to combustibles shown in the figure must be followed. Also refer to the Safety Behaviors and Practices section. The clearance to combustibles from the top is zero.

Rinnai recommends 10” (250 mm) clearance on both sides for servicing.

10"(250mm)

0"

2"

(50mm)

2" (50mm)

40" (1m)

Rinnai Corporation ES38 Manual | 15 |