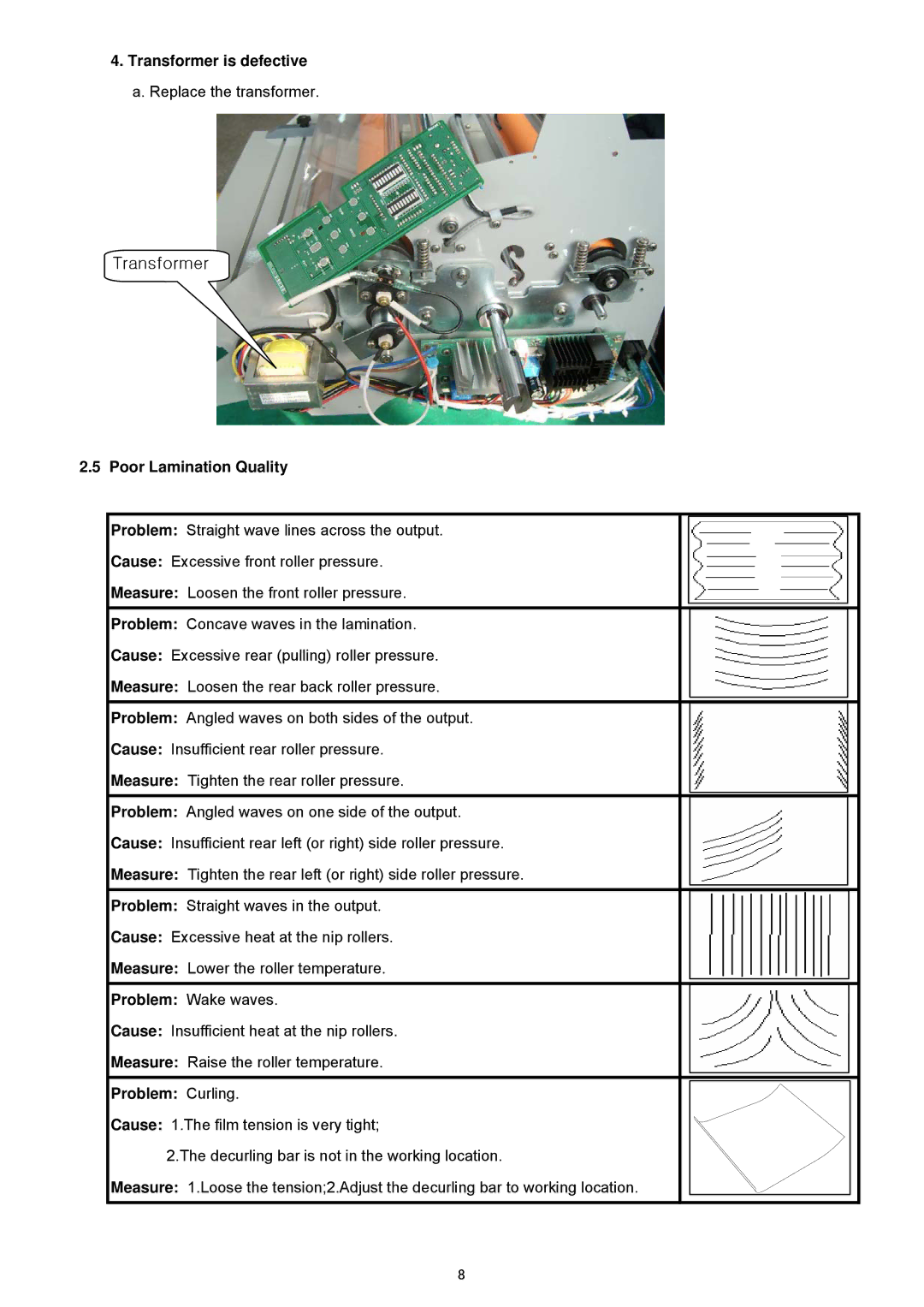

4.Transformer is defective a. Replace the transformer.

Transformer

2.5Poor Lamination Quality

Problem: Straight wave lines across the output.

Cause: Excessive front roller pressure.

Measure: Loosen the front roller pressure.

Problem: Concave waves in the lamination.

Cause: Excessive rear (pulling) roller pressure.

Measure: Loosen the rear back roller pressure.

Problem: Angled waves on both sides of the output.

Cause: Insufficient rear roller pressure.

Measure: Tighten the rear roller pressure.

Problem: Angled waves on one side of the output.

Cause: Insufficient rear left (or right) side roller pressure.

Measure: Tighten the rear left (or right) side roller pressure.

Problem: Straight waves in the output.

Cause: Excessive heat at the nip rollers.

Measure: Lower the roller temperature.

Problem: Wake waves.

Cause: Insufficient heat at the nip rollers.

Measure: Raise the roller temperature.

Problem: Curling.

Cause: 1.The film tension is very tight;

2.The decurling bar is not in the working location.

Measure: 1.Loose the tension;2.Adjust the decurling bar to working location.

8