MAINTENANCE AND REPAIR INSTRUCTIONS (Continued)

3.Initial High Speed Mixture and Idle Speed Mixture Needle Settings: Insert the screwdriver through the hole at the back of the top handle (Fig. 32). Turn both the high speed mixture and idle speed mixture needles out (counterclockwise) until the limiter caps stop.

4.Start the engine and let it run for a minute.

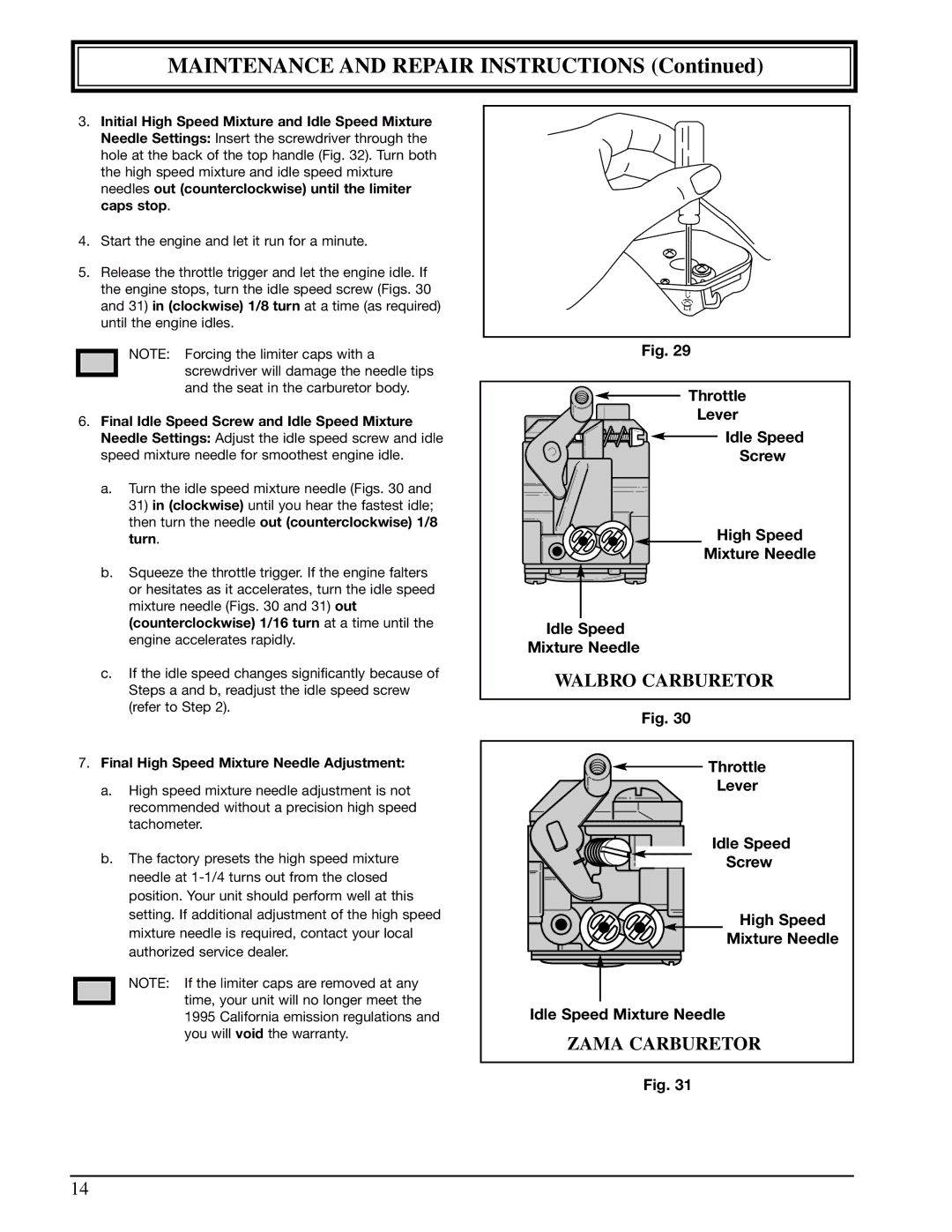

5.Release the throttle trigger and let the engine idle. If the engine stops, turn the idle speed screw (Figs. 30 and 31) in (clockwise) 1/8 turn at a time (as required) until the engine idles.

NOTE: Forcing the limiter caps with a screwdriver will damage the needle tips and the seat in the carburetor body.

6.Final Idle Speed Screw and Idle Speed Mixture Needle Settings: Adjust the idle speed screw and idle speed mixture needle for smoothest engine idle.

a.Turn the idle speed mixture needle (Figs. 30 and 31) in (clockwise) until you hear the fastest idle; then turn the needle out (counterclockwise) 1/8 turn.

b.Squeeze the throttle trigger. If the engine falters or hesitates as it accelerates, turn the idle speed mixture needle (Figs. 30 and 31) out (counterclockwise) 1/16 turn at a time until the engine accelerates rapidly.

c.If the idle speed changes significantly because of Steps a and b, readjust the idle speed screw (refer to Step 2).

7.Final High Speed Mixture Needle Adjustment:

a.High speed mixture needle adjustment is not recommended without a precision high speed tachometer.

b.The factory presets the high speed mixture needle at

NOTE: If the limiter caps are removed at any time, your unit will no longer meet the 1995 California emission regulations and you will void the warranty.

Fig. 29

Throttle

Lever

Idle Speed

Screw

High Speed

Mixture Needle

Idle Speed

Mixture Needle

WALBRO CARBURETOR

Fig. 30

Throttle

Lever

Idle Speed

Screw

High Speed

Mixture Needle

Idle Speed Mixture Needle

ZAMA CARBURETOR

Fig. 31

14