OPERATION

![]() WARNING:

WARNING:

Always wear safety goggles or safety glasses with side shields when using your trimmer. Failure to do so could result in dust, shavings, chips, loose particles, or foreign objects being thrown into your eyes resulting in possible serious injury. If the operation is dusty, also wear a face or dust mask.

![]() WARNING:

WARNING:

When turning your trimmer ON, be prepared for

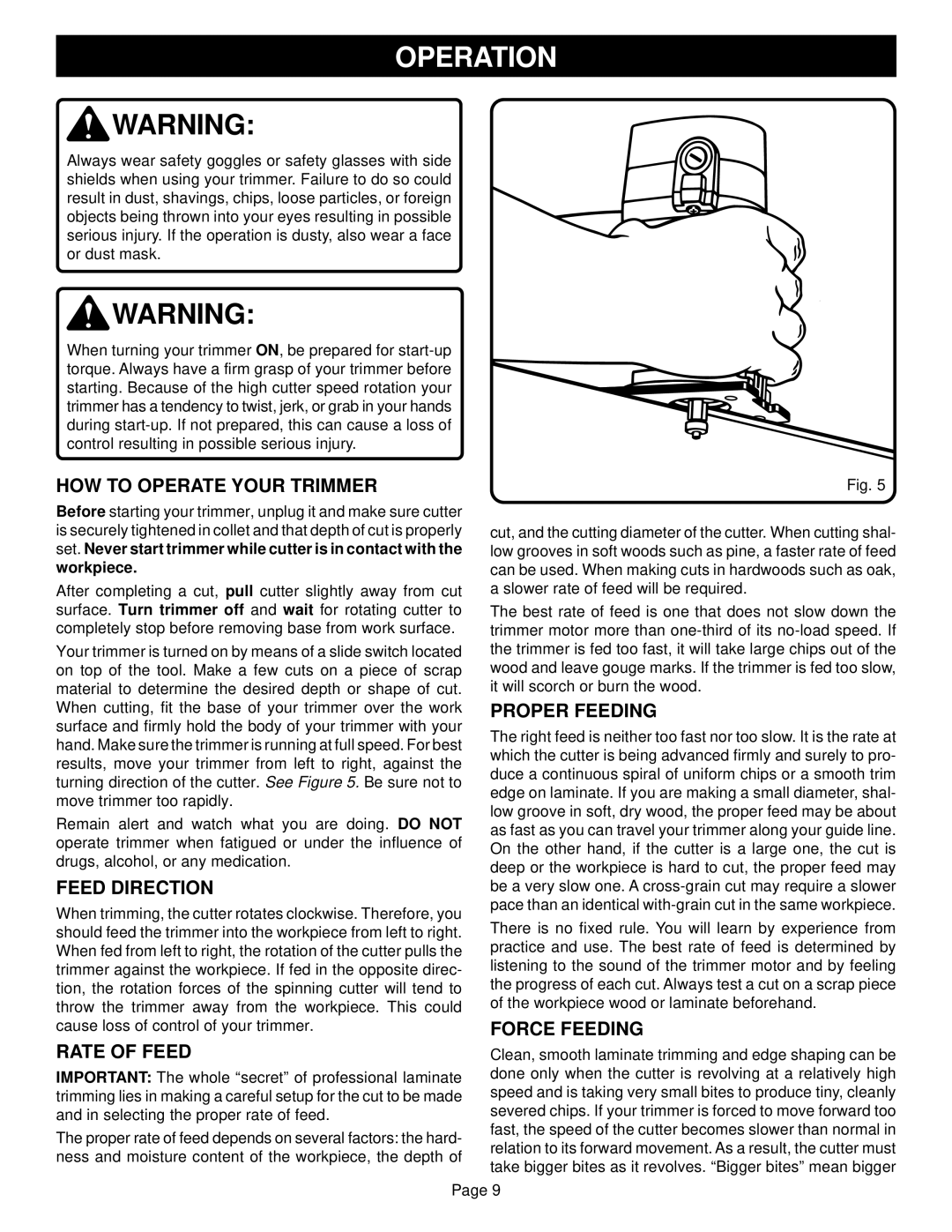

HOW TO OPERATE YOUR TRIMMER | Fig. 5 |

Before starting your trimmer, unplug it and make sure cutter is securely tightened in collet and that depth of cut is properly set. Never start trimmer while cutter is in contact with the workpiece.

After completing a cut, pull cutter slightly away from cut surface. Turn trimmer off and wait for rotating cutter to completely stop before removing base from work surface.

Your trimmer is turned on by means of a slide switch located on top of the tool. Make a few cuts on a piece of scrap material to determine the desired depth or shape of cut. When cutting, fit the base of your trimmer over the work surface and firmly hold the body of your trimmer with your hand. Make sure the trimmer is running at full speed. For best results, move your trimmer from left to right, against the turning direction of the cutter. See Figure 5. Be sure not to move trimmer too rapidly.

Remain alert and watch what you are doing. DO NOT operate trimmer when fatigued or under the influence of drugs, alcohol, or any medication.

FEED DIRECTION

When trimming, the cutter rotates clockwise. Therefore, you should feed the trimmer into the workpiece from left to right. When fed from left to right, the rotation of the cutter pulls the trimmer against the workpiece. If fed in the opposite direc- tion, the rotation forces of the spinning cutter will tend to throw the trimmer away from the workpiece. This could cause loss of control of your trimmer.

RATE OF FEED

IMPORTANT: The whole “secret” of professional laminate trimming lies in making a careful setup for the cut to be made and in selecting the proper rate of feed.

The proper rate of feed depends on several factors: the hard- ness and moisture content of the workpiece, the depth of

cut, and the cutting diameter of the cutter. When cutting shal- low grooves in soft woods such as pine, a faster rate of feed can be used. When making cuts in hardwoods such as oak, a slower rate of feed will be required.

The best rate of feed is one that does not slow down the trimmer motor more than

PROPER FEEDING

The right feed is neither too fast nor too slow. It is the rate at which the cutter is being advanced firmly and surely to pro- duce a continuous spiral of uniform chips or a smooth trim edge on laminate. If you are making a small diameter, shal- low groove in soft, dry wood, the proper feed may be about as fast as you can travel your trimmer along your guide line. On the other hand, if the cutter is a large one, the cut is deep or the workpiece is hard to cut, the proper feed may be a very slow one. A

There is no fixed rule. You will learn by experience from practice and use. The best rate of feed is determined by listening to the sound of the trimmer motor and by feeling the progress of each cut. Always test a cut on a scrap piece of the workpiece wood or laminate beforehand.

FORCE FEEDING

Clean, smooth laminate trimming and edge shaping can be done only when the cutter is revolving at a relatively high speed and is taking very small bites to produce tiny, cleanly severed chips. If your trimmer is forced to move forward too fast, the speed of the cutter becomes slower than normal in relation to its forward movement. As a result, the cutter must take bigger bites as it revolves. “Bigger bites” mean bigger

Page 9