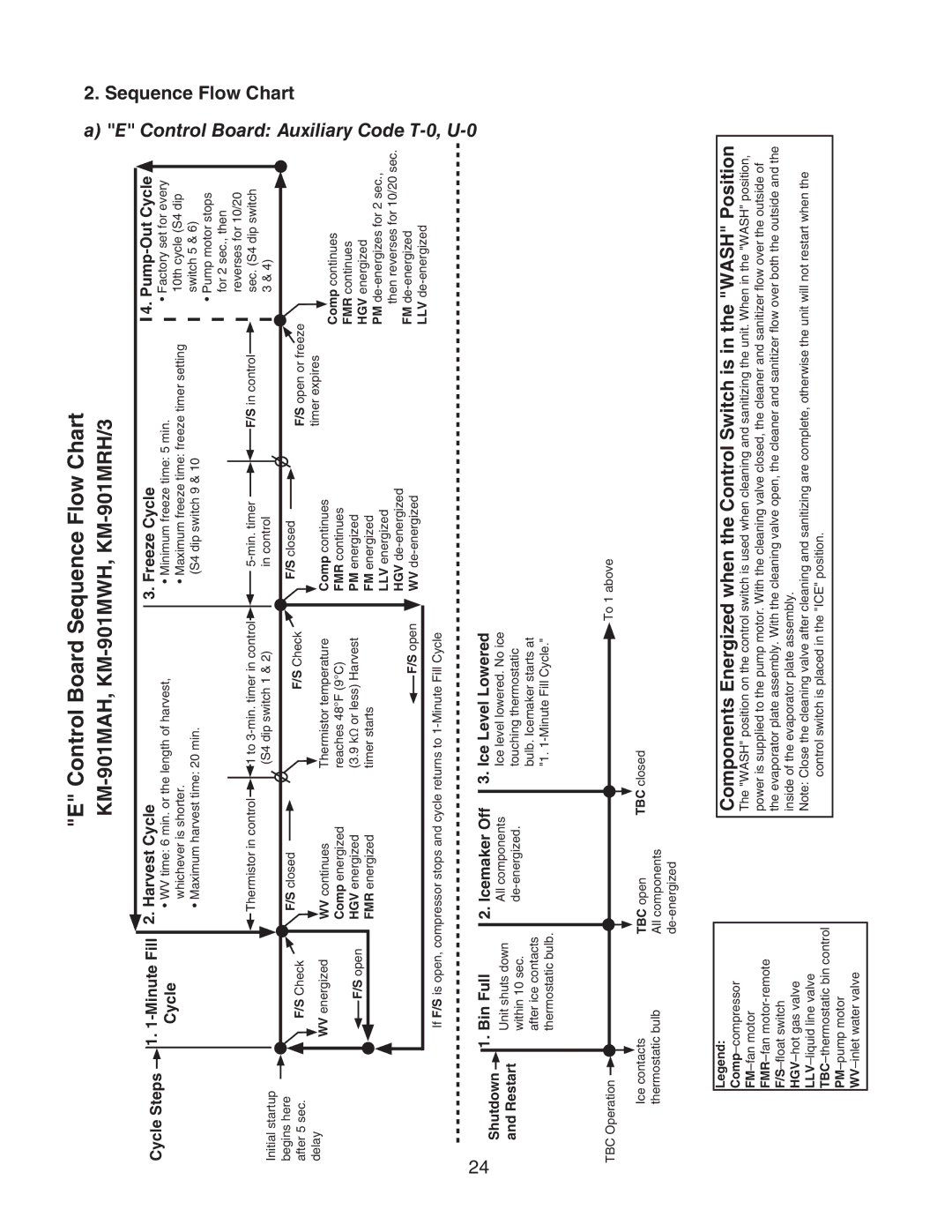

"E" Control Board Sequence Flow Chart

KM-901MAH, KM-901MWH, KM-901MRH/3

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Cycle Steps |

|

|

|

| 1. | 2. Harvest Cycle |

|

|

|

|

| 3. Freeze Cycle |

|

|

| 4. |

| |||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

| ||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

| • Factory set for every |

| ||||||||||||||||||||||||

|

|

| Cycle |

|

|

| • WV time: 6 min. or the length of harvest, |

| • Minimum freeze time: 5 min. |

| ||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

| |||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

| 10th cycle (S4 dip |

| ||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

| whichever is shorter. |

|

|

|

|

|

| • Maximum freeze time: freeze timer setting |

| |||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

| • Maximum harvest time: 20 min. |

| (S4 dip switch 9 & 10 |

|

|

| switch 5 & 6) |

| ||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| • Pump motor stops |

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| for 2 sec., then |

| |

|

|

|

|

|

|

|

|

|

|

|

|

| Thermistor in control |

|

| 1 to |

|

|

|

|

|

|

|

|

| F/S in control |

| reverses for 10/20 |

| |||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| sec. (S4 dip switch |

| |||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||||||||||||||||

Initial startup |

|

|

|

|

|

|

|

|

|

|

|

| (S4 dip switch 1 & 2) |

|

| in control |

|

|

|

| 3 & 4) |

|

| |||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||||||||||||||||||||

begins here |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||

|

|

| F/S Check |

|

|

| F/S closed |

|

|

|

|

| F/S Check |

| F/S closed |

|

|

|

|

|

| F/S open or freeze | ||||||||||||||

after 5 sec. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||||||||||||||

delay |

| WV energized |

|

| WV continues | Thermistor temperature |

| Comp continues |

| timer expires |

|

|

| |||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

| Comp continues | ||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

| Comp energized | reaches 48°F (9°C) |

| FMR continues |

|

|

| ||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| FMR continues | ||||||||||||||||||||

|

|

|

|

|

|

|

|

| F/S open |

|

| HGV energized | (3.9 kΩ or less) Harvest |

| PM energized |

|

|

| ||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| HGV energized | |||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

| FMR energized | timer starts |

| FM energized |

|

|

| ||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| PM | ||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| LLV energized |

|

|

| |||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| then reverses for 10/20 sec. | |||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| HGV |

|

|

| |||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| F/S open |

|

|

|

| FM | |||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| WV |

|

|

| ||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| LLV | ||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||

|

|

|

|

|

|

| If F/S is open, compressor stops and cycle returns to |

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||||||||||||||

a) "E" Control Board: Auxiliary | 2. Sequence Flow Chart |

Code |

|

24 | Shutdown |

|

|

| 1. Bin Full | |

|

|

| ||||

|

|

| Unit shuts down | |||

|

| |||||

| and Restart | |||||

| within 10 sec. | |||||

|

|

|

|

|

| |

|

|

|

|

|

| after ice contacts |

|

|

|

|

|

| thermostatic bulb. |

TBC Operation |

|

|

|

|

| |

|

|

|

|

| ||

2. Icemaker Off |

| 3. Ice Level Lowered |

| ||

All components |

| Ice level lowered. No ice |

| touching thermostatic | |

|

| bulb. Icemaker starts at |

|

| "1. |

|

| To 1 above |

|

|

0 |

Ice contacts | TBC open | TBC closed |

thermostatic bulb | All components |

|

|

|

Legend:

Components Energized when the Control Switch is in the "WASH" Position

The "WASH" position on the control switch is used when cleaning and sanitizing the unit. When in the "WASH" position, power is supplied to the pump motor. With the cleaning valve closed, the cleaner and sanitizer flow over the outside of the evaporator plate assembly. With the cleaning valve open, the cleaner and sanitizer flow over both the outside and the inside of the evaporator plate assembly.

Note: Close the cleaning valve after cleaning and sanitizing are complete, otherwise the unit will not restart when the control switch is placed in the "ICE" position.