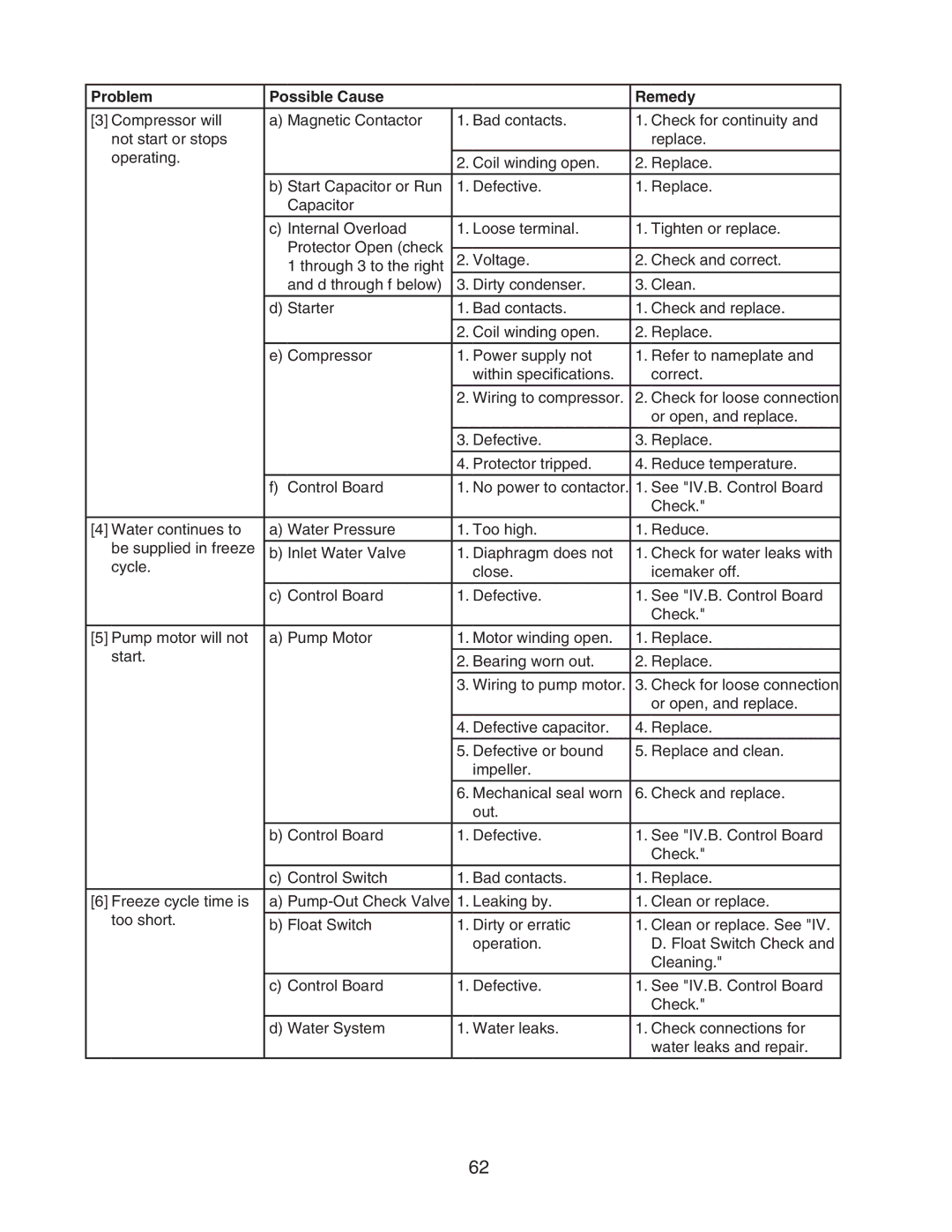

Problem | Possible Cause |

| Remedy | |

|

|

|

| |

[3] Compressor will | a) Magnetic Contactor | 1. Bad contacts. | 1. Check for continuity and | |

not start or stops |

|

| replace. | |

operating. |

| 2. Coil winding open. | 2. Replace. | |

|

| |||

|

|

|

| |

| b) Start Capacitor or Run | 1. Defective. | 1. Replace. | |

| Capacitor |

|

| |

|

|

|

| |

| c) Internal Overload | 1. Loose terminal. | 1. Tighten or replace. | |

| Protector Open (check |

|

| |

| 2. Voltage. | 2. Check and correct. | ||

| 1 through 3 to the right | |||

| and d through f below) | 3. Dirty condenser. | 3. Clean. | |

|

|

|

| |

| d) Starter | 1. Bad contacts. | 1. Check and replace. | |

|

| 2. Coil winding open. | 2. Replace. | |

| e) Compressor | 1. Power supply not | 1. Refer to nameplate and | |

|

| within specifications. | correct. | |

|

|

|

| |

|

| 2. Wiring to compressor. | 2. Check for loose connection | |

|

|

| or open, and replace. | |

|

|

|

| |

|

| 3. Defective. | 3. Replace. | |

|

|

|

| |

|

| 4. Protector tripped. | 4. Reduce temperature. | |

| f) Control Board | 1. No power to contactor. | 1. See "IV.B. Control Board | |

|

|

| Check." | |

|

|

|

| |

[4] Water continues to | a) Water Pressure | 1. Too high. | 1. Reduce. | |

be supplied in freeze |

|

|

| |

b) Inlet Water Valve | 1. Diaphragm does not | 1. Check for water leaks with | ||

cycle. |

| close. | icemaker off. | |

|

| |||

|

|

|

| |

| c) Control Board | 1. Defective. | 1. See "IV.B. Control Board | |

|

|

| Check." | |

[5] Pump motor will not | a) Pump Motor | 1. Motor winding open. | 1. Replace. | |

start. |

|

|

| |

| 2. Bearing worn out. | 2. Replace. | ||

|

| |||

|

|

|

| |

|

| 3. Wiring to pump motor. | 3. Check for loose connection | |

|

|

| or open, and replace. | |

|

|

|

| |

|

| 4. Defective capacitor. | 4. Replace. | |

|

| 5. Defective or bound | 5. Replace and clean. | |

|

| impeller. |

| |

|

|

|

| |

|

| 6. Mechanical seal worn | 6. Check and replace. | |

|

| out. |

| |

|

|

|

| |

| b) Control Board | 1. Defective. | 1. See "IV.B. Control Board | |

|

|

| Check." | |

|

|

|

| |

| c) Control Switch | 1. Bad contacts. | 1. Replace. | |

[6] Freeze cycle time is | a) | 1. Leaking by. | 1. Clean or replace. | |

too short. |

|

|

| |

b) Float Switch | 1. Dirty or erratic | 1. Clean or replace. See "IV. | ||

| ||||

|

| operation. | D. Float Switch Check and | |

|

|

| Cleaning." | |

|

|

|

| |

| c) Control Board | 1. Defective. | 1. See "IV.B. Control Board | |

|

|

| Check." | |

|

|

|

| |

| d) Water System | 1. Water leaks. | 1. Check connections for | |

|

|

| water leaks and repair. |

62