2.Bend the connection pipe to an appropriate length using a bender depending upon the installation place.

3.Perform pipe bending process.

4.Connect the high pressure pipe (ø6.35mm) and low pressure pipe (ø15.88mm) to the high/low pressure pipe of the outdoor unit and tightening by applying appropriate torque.

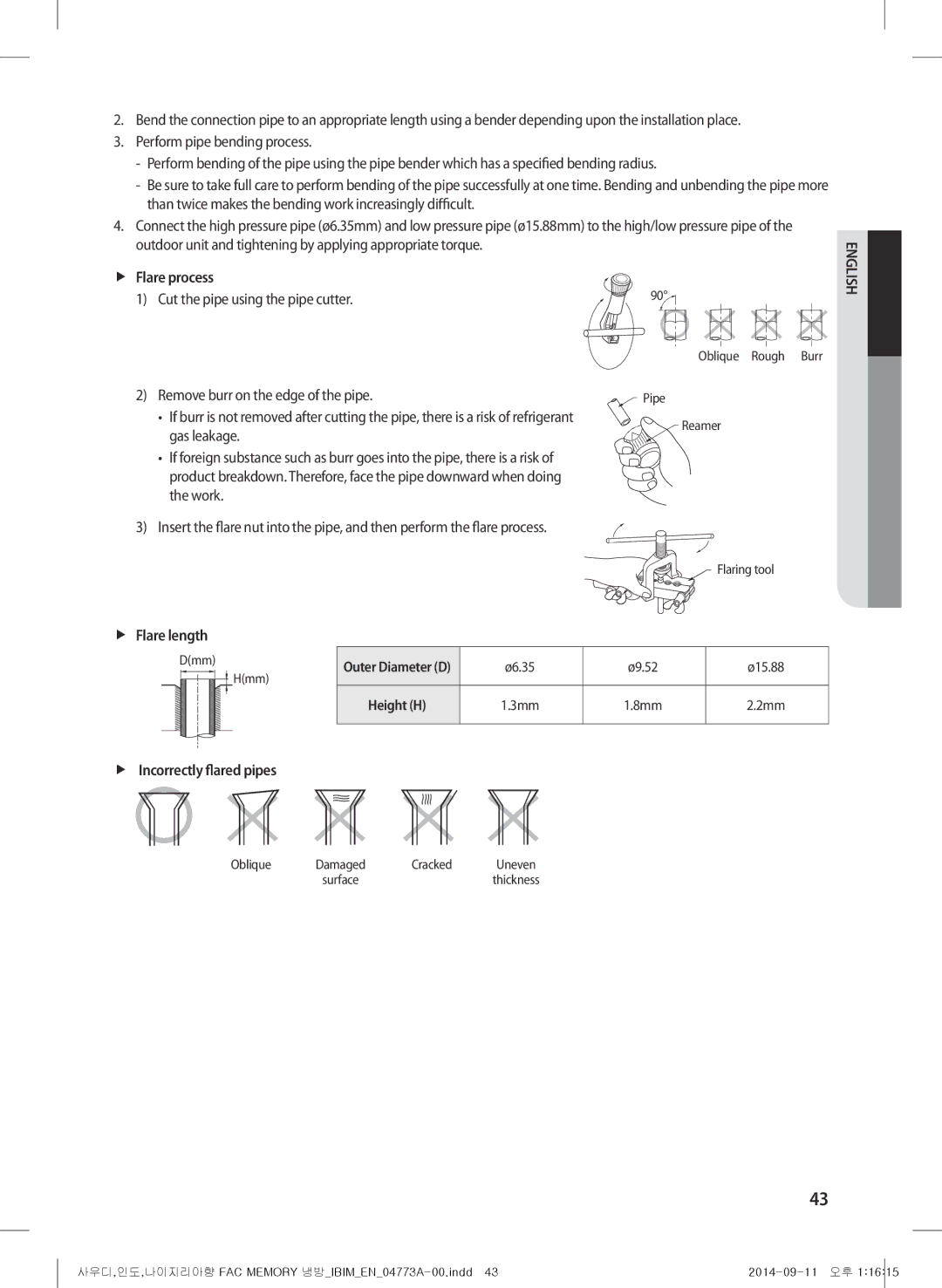

ffFlare process

1) Cut the pipe using the pipe cutter. | 90° |

Oblique Rough Burr

2) Remove burr on the edge of the pipe. | Pipe | |

• If burr is not removed after cutting the pipe, there is a risk of refrigerant | Reamer | |

gas leakage. | ||

|

• If foreign substance such as burr goes into the pipe, there is a risk of product breakdown. Therefore, face the pipe downward when doing the work.

3) Insert the flare nut into the pipe, and then perform the flare process.

Flaring tool

ffFlare length

D(mm) | Outer Diameter (D) | ø6.35 | ø9.52 | ø15.88 |

| ||||

| H(mm) |

|

|

|

| Height (H) | 1.3mm | 1.8mm | 2.2mm |

ENGLISH

ffIncorrectly flared pipes

Oblique | Damaged | Cracked | Uneven |

| surface |

| thickness |

43

사우디,인도,나이지리아향 FAC MEMORY |