Cutting or extending the pipe

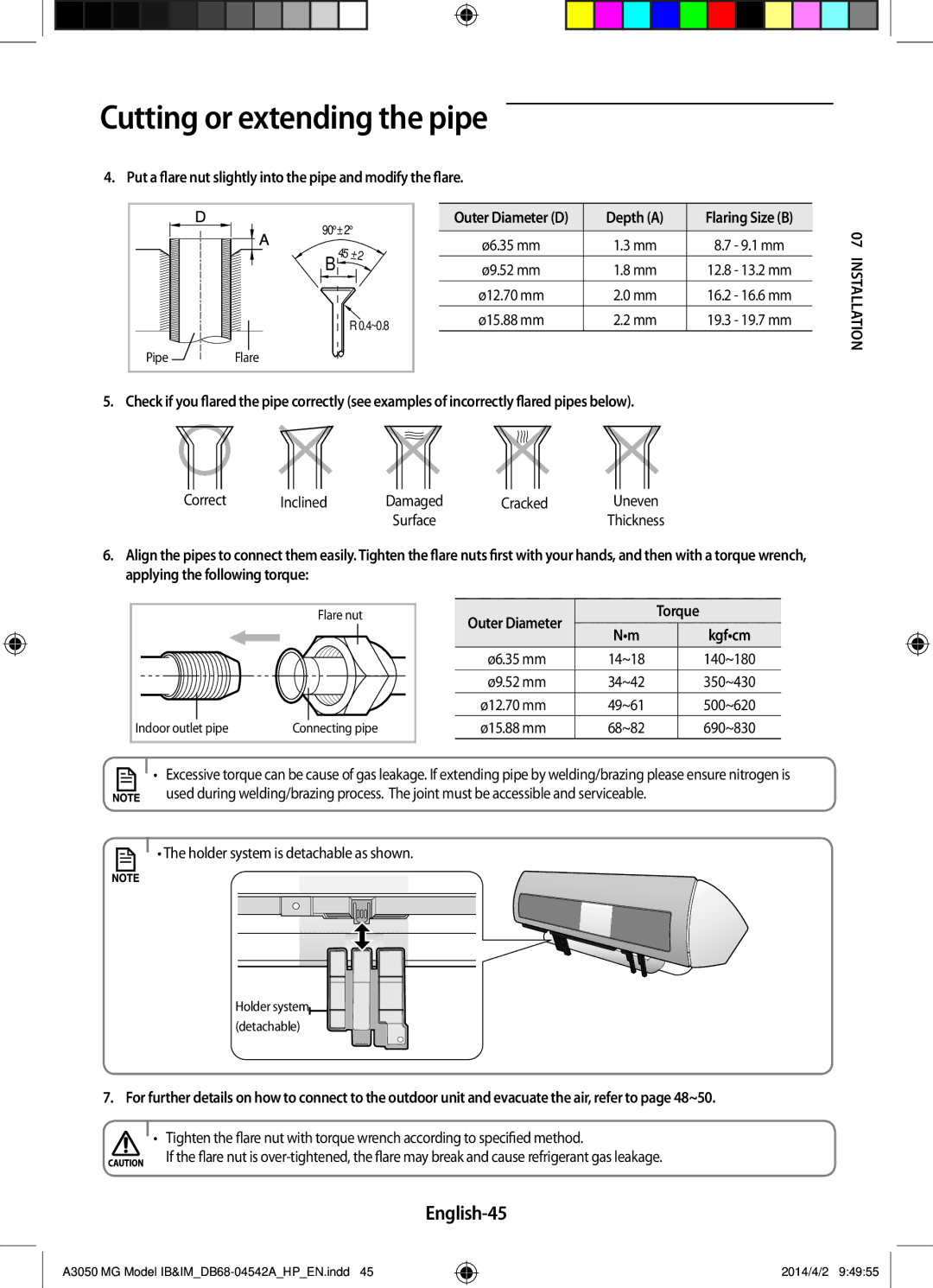

4. Put a flare nut slightly into the pipe and modify the flare.

90°±2°

| 4 |

|

| 5°± | |

B |

| 2° |

|

| |

R0.4~0.8

Pipe ![]() Flare

Flare

Outer Diameter (D) | Depth (A) | Flaring Size (B) | |

|

|

|

|

ø6.35 mm | 1.3 mm | 8.7 | - 9.1 mm |

ø9.52 mm | 1.8 mm | 12.8 | - 13.2 mm |

ø12.70 mm | 2.0 mm | 16.2 | - 16.6 mm |

ø15.88 mm | 2.2 mm | 19.3 | - 19.7 mm |

07 INSTALLATION

5. Check if you flared the pipe correctly (see examples of incorrectly flared pipes below).

Correct | Inclined | Damaged | Cracked | Uneven |

|

| Surface |

| Thickness |

6.Align the pipes to connect them easily. Tighten the flare nuts first with your hands, and then with a torque wrench, applying the following torque:

Flare nut

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Indoor outlet |

| pipe |

|

|

|

| ||||

| Connecting pipe | |||||||||

Outer Diameter |

| Torque | |

|

|

| |

N•m |

| kgf•cm | |

|

| ||

|

|

|

|

ø6.35 mm | 14~18 |

| 140~180 |

ø9.52 mm | 34~42 |

| 350~430 |

ø12.70 mm | 49~61 |

| 500~620 |

ø15.88 mm | 68~82 |

| 690~830 |

• Excessive torque can be cause of gas leakage. If extending pipe by welding/brazing please ensure nitrogen is used during welding/brazing process. The joint must be accessible and serviceable.

• The holder system is detachable as shown.

Holder system![]()

![]() (detachable)

(detachable)

7. For further details on how to connect to the outdoor unit and evacuate the air, refer to page 48~50.

• Tighten the flare nut with torque wrench according to specified method.

If the flare nut is

English-45

A3050 MG Model

2014/4/2 9:49:55