Step 2.4 Optional: Extending the power cable

1Prepare a compressor and the following tools.

Tools | Spec | Shape |

Crimping pliers |

| |

Connection sleeve | 20xØ7.0 |

|

(mm)(HxOD)

Insulation tape | Width 18 | |

mm | ||

| ||

|

| |

Contraction tube | 50xØ8.0 | |

(mm) | (LxOD) |

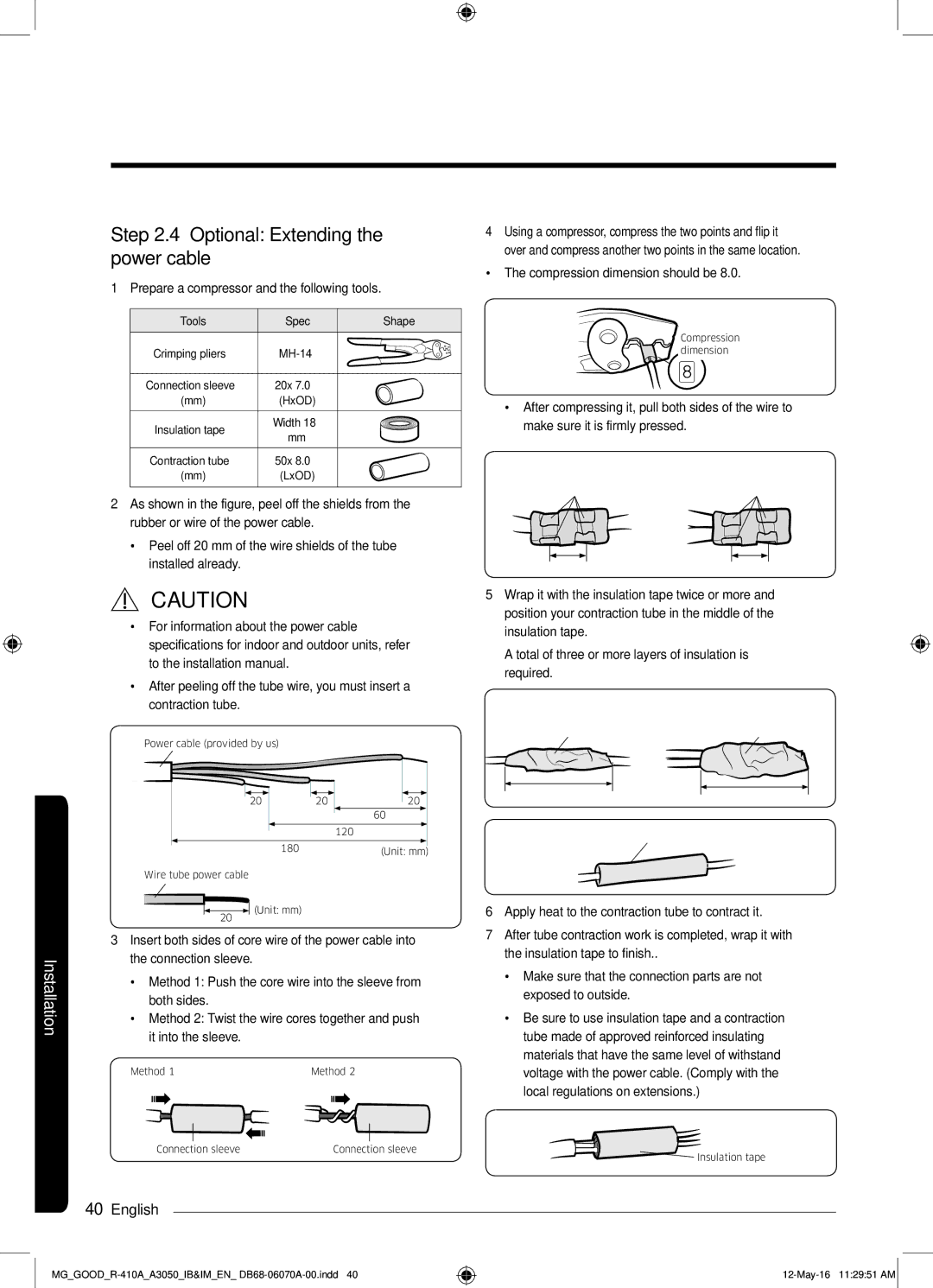

2As shown in the figure, peel off the shields from the rubber or wire of the power cable.

•Peel off 20 mm of the wire shields of the tube installed already.

![]() CAUTION

CAUTION

•For information about the power cable specifications for indoor and outdoor units, refer to the installation manual.

•After peeling off the tube wire, you must insert a contraction tube.

Power cable (provided by us)

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 20 |

|

| 20 |

|

|

|

|

| 20 |

|

| ||

|

|

|

|

|

|

|

|

|

|

|

|

| ||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 60 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

| 120 |

|

|

|

|

|

| ||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 180 |

|

|

|

|

| (Unit: mm) | |||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||||

|

|

| Wire tube power cable |

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||||

|

|

|

|

|

|

|

|

| (Unit: mm) |

|

|

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||

|

|

|

|

|

| 20 |

|

|

|

|

|

|

|

|

|

|

|

| ||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||||

| 3 Insert both sides of core wire of the power cable into | |||||||||||||||||||||

Installation |

| the connection sleeve. |

|

|

|

|

|

|

|

|

|

|

| |||||||||

| • Method 1: Push the core wire into the sleeve from | |||||||||||||||||||||

|

| |||||||||||||||||||||

|

|

| both sides. |

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||||

|

| • Method 2: Twist the wire cores together and push | ||||||||||||||||||||

|

|

| it into the sleeve. |

|

|

|

|

|

|

|

|

|

|

| ||||||||

|

| Method 1 |

|

|

| Method 2 |

|

|

|

|

|

| ||||||||||

Connection sleeve | Connection sleeve |

40English

4Using a compressor, compress the two points and flip it over and compress another two points in the same location.

•The compression dimension should be 8.0.

Compression dimension

•After compressing it, pull both sides of the wire to make sure it is firmly pressed.

Method 1 | Method 2 |

Compress it 4 times. | Compress it 4 times. |

5 mm | 5 mm |

5Wrap it with the insulation tape twice or more and position your contraction tube in the middle of the insulation tape.

A total of three or more layers of insulation is required.

Method 1 |

| Method 2 | ||

| Insulation tape |

| Insulation tape | |

|

|

|

|

|

|

|

|

|

|

| 40 mm |

|

| |

|

| 35 mm | ||

|

| |||

|

|

|

| |

|

|

| Contraction tube | |

6Apply heat to the contraction tube to contract it.

7After tube contraction work is completed, wrap it with the insulation tape to finish..

•Make sure that the connection parts are not exposed to outside.

•Be sure to use insulation tape and a contraction tube made of approved reinforced insulating materials that have the same level of withstand voltage with the power cable. (Comply with the local regulations on extensions.)

![]()

![]()

![]() Insulation tape

Insulation tape

MG_GOOD_R-410A_A3050_IB&IM_EN_ DB68-06070A-00.indd 40

![]()