63230-314-200C2 specifications

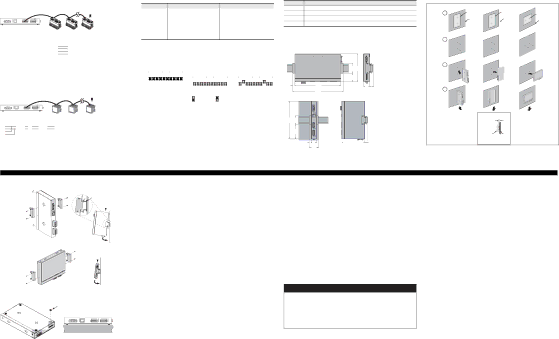

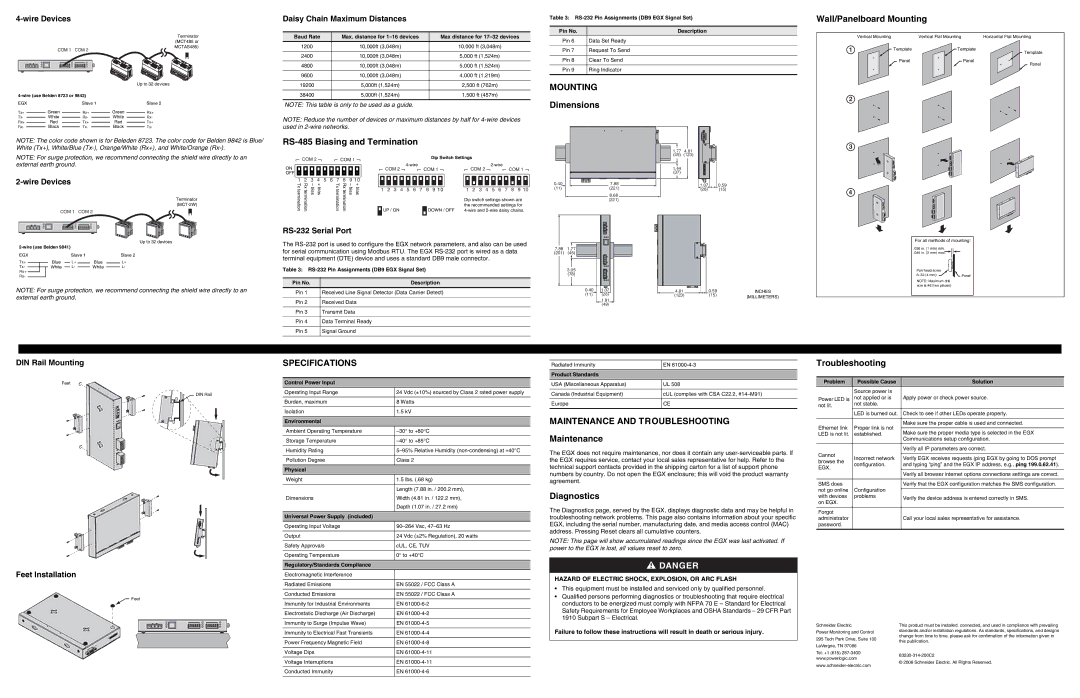

Schneider Electric is a global leader in energy management and automation, renowned for providing innovative solutions tailored to various industrial needs. Among its extensive portfolio, the Schneider Electric 63230-314-200C2 stands out, representing an exemplary product characterized by its versatility and advanced technology.The Schneider Electric 63230-314-200C2 is primarily designed for monitoring and controlling electrical systems, making it essential for efficient energy management. One of its main features includes a robust communication interface that supports multiple protocols, enabling seamless integration with existing systems and enhancing interoperability. This functionality allows users to easily adopt smart technologies and optimize their energy consumption.

Another significant characteristic of the 63230-314-200C2 is its user-friendly interface. The device comes equipped with an intuitive display that offers real-time data visualization, ensuring that operators can monitor system performance at a glance. This feature reduces the complexity typically associated with industrial devices, allowing users to focus on critical decision-making processes without getting bogged down by technicalities.

The technology behind the 63230-314-200C2 showcases Schneider Electric's commitment to sustainability and efficiency. It utilizes advanced algorithms that facilitate energy data analysis, helping users identify trends and patterns that can lead to significant cost savings. By leveraging this information, companies can make informed choices about their energy usage, ultimately reducing their carbon footprint.

Safety is another paramount consideration, and the 63230-314-200C2 addresses this by incorporating various protective features. It is designed to withstand harsh industrial environments, ensuring reliable operation under challenging conditions. Furthermore, the product meets stringent international safety standards, providing users with peace of mind regarding its reliability and effectiveness.

In conclusion, the Schneider Electric 63230-314-200C2 embodies a blend of innovation, user-centric design, and sustainability. Its robust communication capabilities, intuitive interface, energy analysis technologies, and safety features make it an invaluable asset for any organization looking to optimize its electrical systems. As industries increasingly pivot towards smart energy solutions, the Schneider Electric 63230-314-200C2 positions itself as a forward-thinking choice that aligns with modern operational demands.