WARNING TO SERVICE PERSONNEL

TABLE OF CONTENTS

WARNING TO SERVICE PERSONNEL

MICROWAVE MEASUREMENT PROCEDURE

BEFORE SERVICING

After repairing

WARNING TO SERVICE PERSONNEL

Before Servicing

When the testing is completed

B. Preparation for testing

MICROWAVE MEASUREMENT PROCEDURE

A. Requirements

C. Leakage test

1440 Bridge Gate Dr Diamond Bar, CA

DANGER

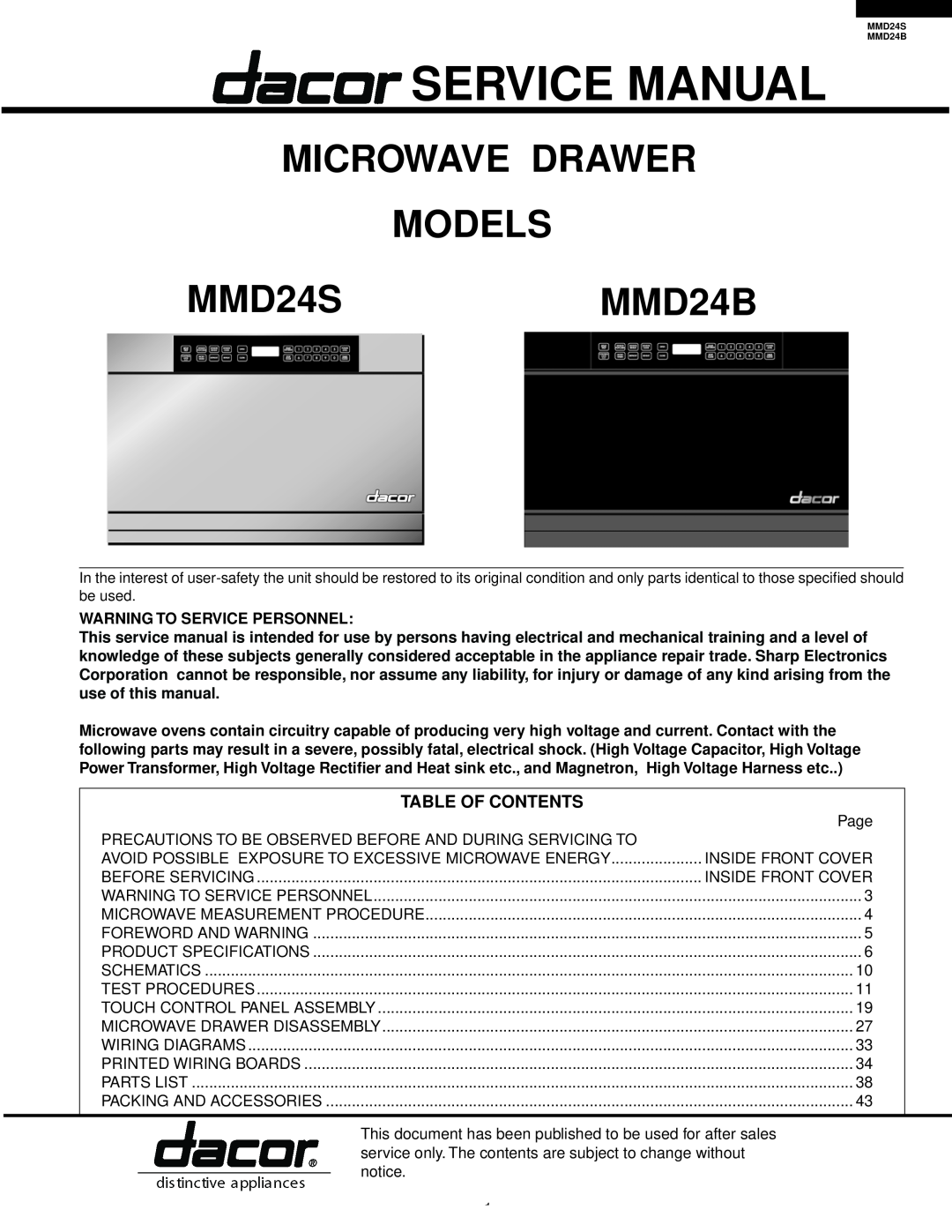

SERVICE MANUAL

If provided, Vent Hood, Fan assembly, Cooling Fan Motor

DESCRIPTION

MICROWAVE DRAWER SPECIFICATION

GROUNDING INSTRUCTIONS

GENERAL INFORMATION

OPERATION

POWER LEVEL P-0 TO P-90 COOKING

DESCRIPTION OF OPERATING SEQUENCE

OFF CONDITION

Cooking Sequence

SENSOR COOKING CONDITION

MICROWAVE

CLOSED, COOK OFF CONDITTION

SCHEMATIC OFF CONDITION

DOOR

PROCEDURE

TEST PROCEDURES

A TOUCH CONTROL PANEL ASSEMBLY TEST

Before testing

B KEY UNIT TEST

COMPONENT TEST

C RELAY TEST

DEFROST TEST

Check supply voltage and oven power cord

STEPS

The rated AC voltage is not present between

F AH SENSOR TEST Checking the initial sensor cooking condition

TESTING METHOD FOR AH SENSOR AND/OR CONTROL UNIT

Water load cooking test

R1, R2 22Ω ± 1% 1/2W R3 4.3kΩ ± 5% 1/4W R4 1MΩ ± 5% 1/4W

CHECKING CONTROL UNIT

G MAGNETRON ASSEMBLY TEST

Refer to the disassembly instructions found on Page

MICROWAVE OUTPUT POWER

H THERMAL CUT-OUT TEST

J STOP SWITCH TEST

I SECONDARY INTERLOCK SWITCH TEST

K MONITOR SWITCH TEST

L BLOWN MONITOR FUSE TEST

M POWER TRANSFORMER TEST

Control Unit and Power Unit

TOUCH CONTROL PANEL ASSEMBLY

4 Reset Circuit

5 Indicator Circuit

Power source voltage 0V GND

DESCRIPTION OF LSI IC-1

Internal clock oscillation frequency setting input

Power source voltage +5V

Segment data signal

Signal

Signal coming from touch key

Signal similar to P23

Common relay driving signal. Square Waveform 60Hz

Magnetron high-voltage circuit driving signal

Signal to sound buzzer

Signal to synchronize LSI with commercial power source frequency

ventilation opening for sensing

HUMIDITY SENSOR CIRCUIT

1 Structure of Humidity Sensor

2 Operational Principle of Humidity Sensor

1 Servicing the touch control panel with power supply of the oven

TOUCH CONTROL PANEL SERVICING

4. Other Precautions

2. Servicing of Touch Control Panel

2. Using lead-free wire solder

PRECAUTIONS FOR USING LEAD-FREE SOLDER

1. Employing lead-free solder

3. Soldering

WARNING FOR WIRING

COMPONENT REPLACEMENT AND ADJUSTMENT PROCEDURE

WARNING AGAINST HIGH VOLTAGE

To prevent an electric shock, take the following pre- cautions

MICROWAVE DRAWER DISASSEMBLY

Un-hook/Attach Black AC Wire to Top Terminal

POWER CORD REPLACEMENT

Un-hook/Attach White AC Wire to Bottom Terminal

Un-hook/Attach Ground to metal Tab on Back Plate

STOP SWITCH, SECONDARY INTERLOCK SWITCH AND MONITOR SWITCH ADJUSTMENT

STOP SWITCH, SECONDARY INTERLOCK SWITCH AND MONITOR SWITCH REMOVAL

Re-install

After adjustment, check the following

DRAWER SUPPORT ANGLE REMOVAL

DRAWER ASSEMBLY AND CHOKE REMOVAL

DRAWER/SLIDE RAIL REMOVAL

1. Follow the Microwave Drawer disassembly as previously

SWITCH ANGLE REMOVAL

SWITCH ANGLE REMOVAL/ADJUSTMENT

ACTUATOR REMOVAL/ADJUSTMENT

Actuator adjustment

Bottom cover

AUTO DRAWER GEAR REMOVAL/INSTALLATION

RACK GEAR REMOVAL

Installation

to Back Plate

HIGH VOLTAGE COMPONENTS

MICRO

Figure S-2. Power Unit Circuit

FM A

CN-A

CONTROL

UNIT

UNIT

F G H

2.5A

Figure S-4. Printed Wiring Board of Power Unit

A B C D E F G H

UnitControlof

5.PrintedWiringBoard

COPYRIGHT 2008 BY DACOR, INC ALL RIGHTS RESERVED