Maintenance

IMPORTANT!

For detailed maintenance information about your T230/231, AH230/231, or PB230, consult the owner's manual that was provided with it. If it has been lost or misplaced, contact Shindaiwa for a replacement.

WARNING!

Before performing any maintenance, repair, or cleaning work on the unit, make sure the engine and cutting attachment are completely stopped. Disconnect the spark plug wire before performing service or mainte- nance work.

![]() WARNING!

WARNING!

IMPORTANT!

Using

Daily Maintenance

![]() WARNING!

WARNING!

The saw chain is very sharp. Wear gloves to protect your hands when working with or around the saw chain.

15-hour Maintenance

Every 15 hours of operation (more frequently in dusty or dirty conditions):

Remove the sprocket cover and inspect the sprocket (A) for excessive dirt, debris, or wear. Remove the guide bar and clean out the guide bar groove. If the sprocket is excessively worn, replace it with a new one.

Prior to each work day, perform the follow- | Check for loose or missing screws or | |

ing: | components. | |

Clean any debris or dirt from the | Check the entire machine for leaking | |

cutting attachment. Check the bar | fuel or grease. | |

and chain for damage or incorrect | Make sure that nuts, bolts, and | |

adjustment. | ||

screws (except carburetor adjusting | ||

| ||

| screws) are tight. |

A

Every 50 hours of operation (more frequently in dusty or dirty conditions):

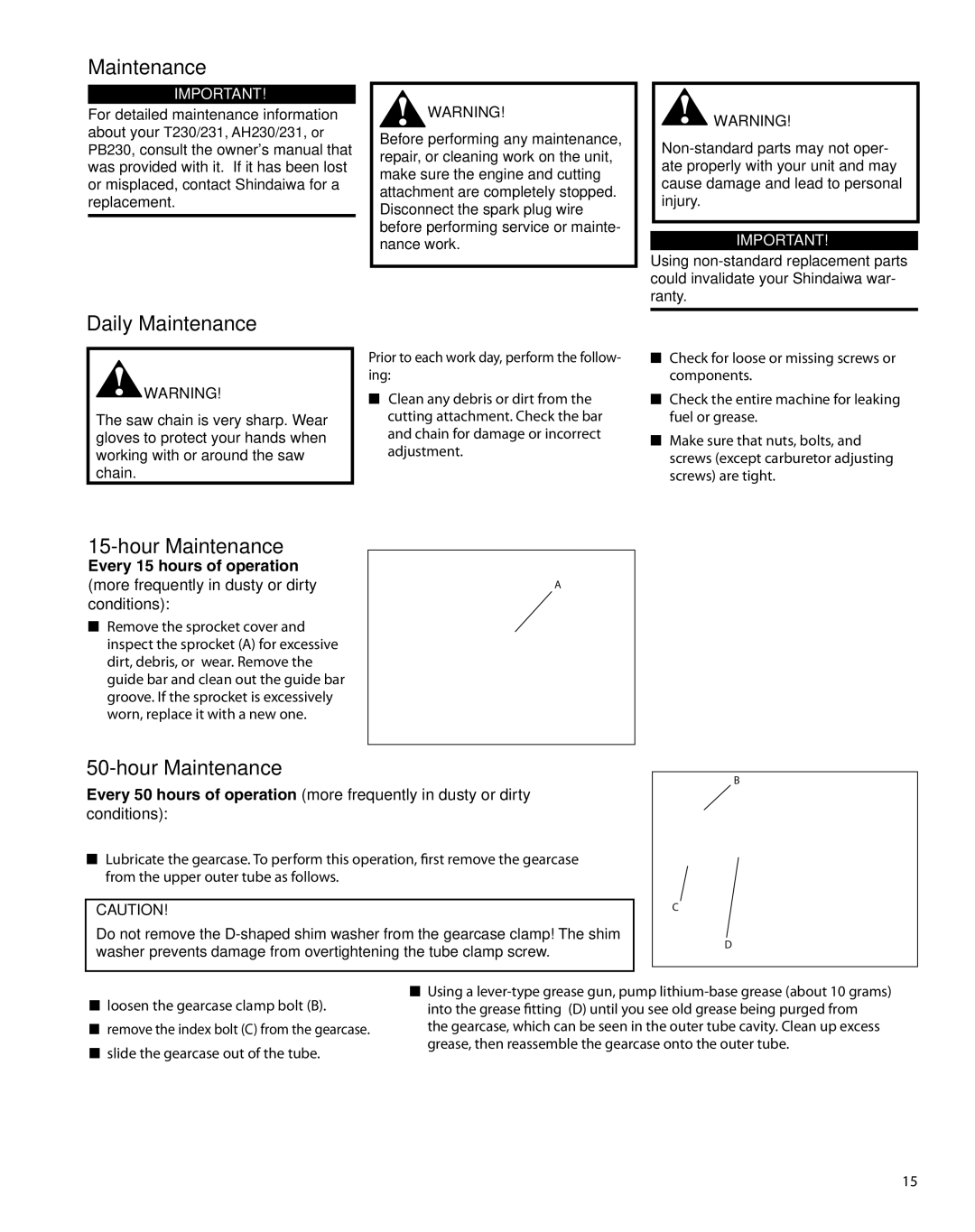

Lubricate the gearcase. To perform this operation, first remove the gearcase from the upper outer tube as follows.

CAUTION!

Do not remove the

B

C

D

■■loosen the gearcase clamp bolt (B).

■■remove the index bolt (C) from the gearcase. ■■slide the gearcase out of the tube.

■■Using a

15