Assembly

This unit comes fully assembled with the exception of the cutting attachment shield and cutting attachment.

IMPORTANT!

The terms “left”,

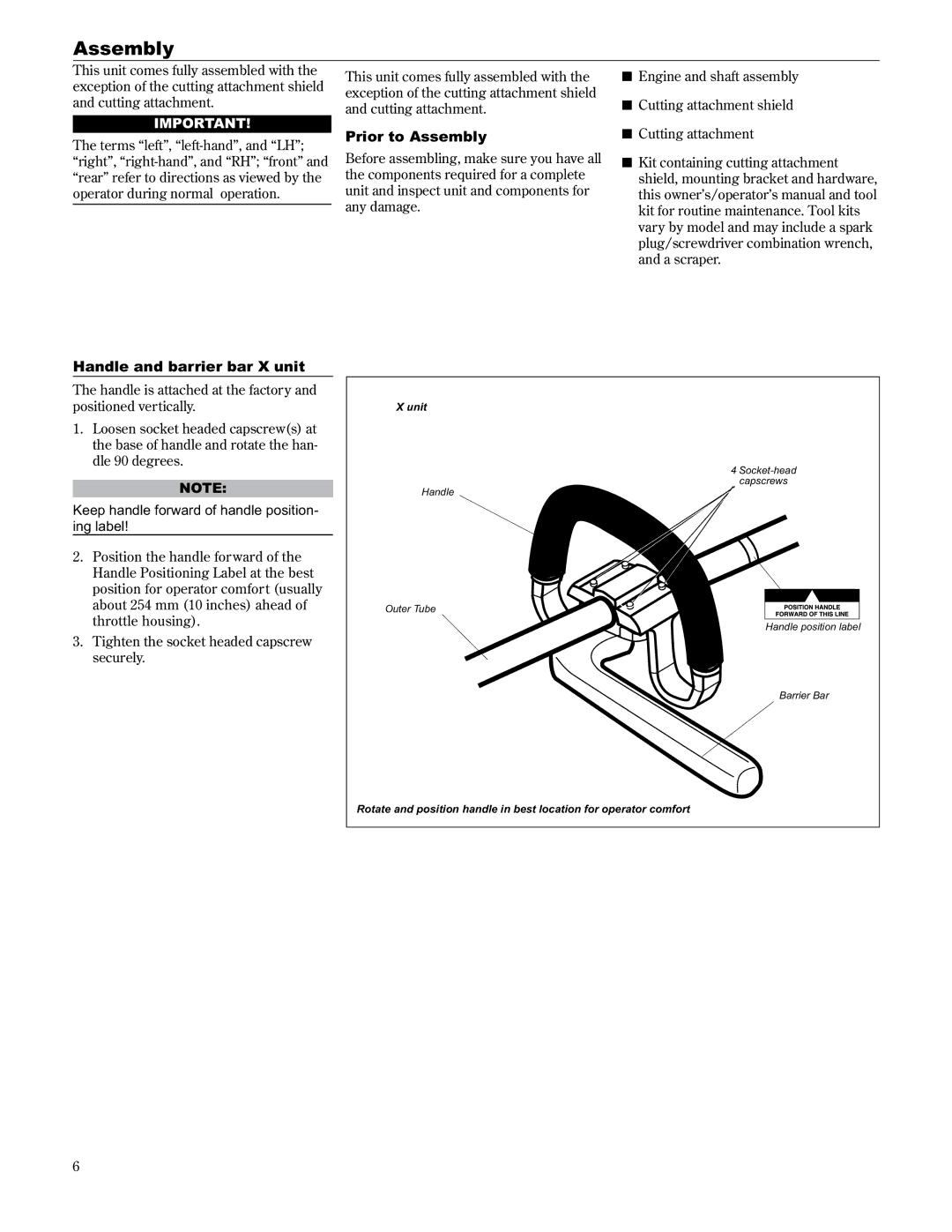

Handle and barrier bar X unit

The handle is attached at the factory and positioned vertically.

1.Loosen socket headed capscrew(s) at the base of handle and rotate the han dle 90 degrees.

NOTE:

Keep handle forward of handle position- ing label!

2.Position the handle forward of the Handle Positioning Label at the best position for operator comfort (usually about 254 mm (10 inches) ahead of throttle housing).

3.Tighten the socket headed capscrew securely.

This unit comes fully assembled with the exception of the cutting attachment shield and cutting attachment.

Prior to Assembly

Before assembling, make sure you have all the components required for a complete unit and inspect unit and components for any damage.

X unit

Handle

Outer Tube

ŶEngine and shaft assembly

ŶCutting attachment shield

ŶCutting attachment

ŶKit containing cutting attachment shield, mounting bracket and hardware, this owner’s/operator’s manual and tool kit for routine maintenance. Tool kits vary by model and may include a spark plug/screwdriver combination wrench, and a scraper.

4

Handle position label

Barrier Bar

Rotate and position handle in best location for operator comfort

6