Gigaset 2011 Tango

KAP00.FM5

Carrying clip

Overview Gigaset 2011 Tango

Display symbols

Overview Key functions and display symbols

Key function

Only use rechargeable bat

Safety precautions

As shown

Type according to instruc

Certification and CE marking

Contents

Contents

Index

Check the contents of the package

Observe the safety precautions

Connecting the base station

Stepwise startup

Inserting the batteries into the handset

Power cord

Phone cord

Stepwise startup Charging the batteries

Check signaling method

Menu-driven operation

Menu-driven operation

Menu structure

Moving to higher menu levels and leaving a menu

Abbreviated presentation

Settings Handset Settings Beeps Confirm beep

Store

UW t New Entry

Operating modes

Switching the handset to protected mode

Operating modes

ON/OFF/PROTECTED modes

When the handset is switched off

Signaling method

Switching off the handset

Checking the signaling method of your telephone line

Incoming calls

Incoming calls

Accepting calls

If the handset is in the charging unit

Ending a call

Incoming calls External call-waiting during internal calls

External outgoing calls

External outgoing calls

Calling external subscribers

Dialing with call number checking en-bloc dialing

Redial

No answer or line busy

Manually inserting a pause

Pause

Call up directory

External outgoing calls Dialing using the directory

Dial number

Dialing a DSS number from a locked handset

Switch to Tone

If the base station is locked

Collective ringing and internal calls

Collective ringing and internal calls

Making internal calls

End call prematurely

Ending an internal call

Switching off the microphone mute function

Disconnect internal party again

Internal consultation calls and transferring calls

Internal consultation calls and transferring calls

Consultation calls

When more than one handsets are in operation Either

Creating and managing the directory

Creating and managing the directory

UW t e.g. New Entry

New Entry

Save Entry Cancel Display special character

U W t New Entry

Inserting a pause

Editing an entry T Edit Entry

Copying numbers T Copy Number

Process and save entry

Available memory

Delete directory

Delete entry T Delete Entry x OK

UW t Delete Directory

Input function

Input function

Input field

First digit, in this

Example of a new directory entry

Tered

You can also make corrections while making new entries

Example of field boundaries

Entering letters, special characters, and digits

Name entry field 123 789 C, d....x, y, z Character set

Content input field

Default setting = lower case

Key Press

Shift to upper case by pressing

Base station settings

Base station settings

Service function

Service Call up the Service menu item

Base station settings Setting the base station ringer tone

Handset settings

Handset settings

Setting the handset volume

Settings t Handset volume

Settings t Ringer Options t followed by

Handset settings Ringer settings

OK or u

Activating/deactivating the call duration display

Activating/deactivating automatic backlight

Handset settings Selecting a language

Automatic call acceptance

Base station has moved back into range

Settings t Handset Settings t Beepst followed by

Activating/deactivating the baby alarm

Handset settings Baby alarm

Baby Alarm

Store Cancel

Switch on the lock Switch off the lock

Emergency calls when the Gigaset 2011 Tango is locked

Gigaset 2011 Tango lock functions

Gigaset 2011 Tango lock functions

Deleting all emergency numbers

Displaying and storing emergency numbers

Number from being dialed if the call number lock is acti

#8% Start the setting procedure

Rate numbers, e.g. numbers starting with

Set. Barred numbers can have up to eight digits

Deleting all barred numbers

Factory default setting is off

Number lock is switched on

#84 Start the setting procedure

Not affected by the lock

Tmeans browse using x Z, confirm using u OK

Lock functions on the handset

Lock functions on the handset

Activating/deactivating the handset lock

Handset Lock t Lock on/off

Deleting a DSS number

Display or store a DSS number

Save Entry

Dialing a DSS number

Display with locked handset

Handset lock is switched on and a DSS number is stored

Display with system lock

Display with call number lock

Short cuts

Short cuts

Descriptions with example

Short cut menu

T New Entry

Short cuts New entry

Function list

Insert Function

Cancel Checking for double entries

Save Entry Cancel procedure

Insert Function t Request Number

Displaying a function

Deleting an entry

Short cuts Editing an entry

Displaying an entry

T Delete Entry

Starting a short cut

Short cuts Deleting all entries

T Available Memory

T Start

Restoring default short cuts

Short cuts Default short cuts

Procedure

T Default short cuts

Operating more than one handset

Operating more than one handset

Registering a Gigaset 2000C Tango handset at a base station

Ring priority for incoming calls

Switching between collective ringing and ring priority

SET Set collective ringing SET Set ring priority

Selecting a handset for ring priority

Enter the desired number of rings two to nine and con- firm

Setting the number of rings for ring priority Service

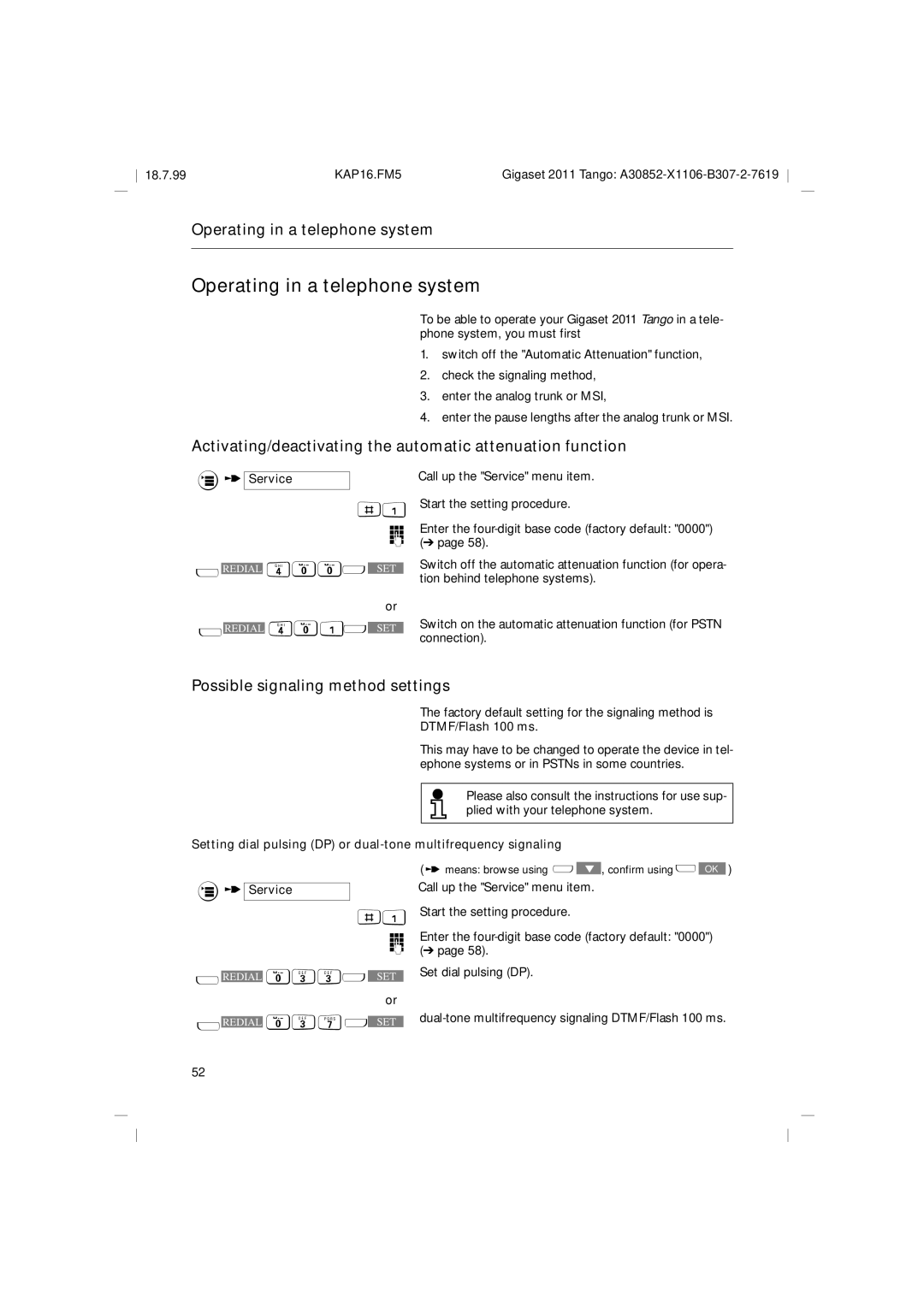

Operating in a telephone system

Possible signaling method settings

Operating in a telephone system

Activating/deactivating the automatic attenuation function

Deleting the analog trunk/MSI

Analog trunks

Delete analog trunk/MSI

Entering the analog trunk and the MSI

Operation at more than one base station

Procedure for operating at more than one base station

Operation at more than one base station

Selecting the best station

Select Base

Selecting the fixed station

T Fixed Selection Searching for the preferred station

T Priority Select

De-registering a base station

Operation at more than one base station Base station names

Code numbers and factory defaults

Code numbers and factory defaults

Changing the system code, changing the PIN

Changing the system code

Service Redial 2 %0x SET

Resetting the base station to factory defaults

Changing the handset PIN

Confirming the PIN resets the settings to factory de

Default

Faults

Initialization

Installation site/installation area

Installing the base station

Power socket must be located at the installation site

Temperature/ambient conditions

KAP18.FM5

Mounting the carrying clip onto the handset

NiMH, 1100 mAh

Standard

Technical data

Prox W, during charging approx W

Up to 130 hours

Maintenance notes

Connecting the telephone socket

Third party use/disposal

Symptom Cause Remedy

Procedure in the case of malfunctions

Volume

Remove it and plug it back

Recall Tuuuuut Internal dial tone

Overview signal tones

Batt. low Tuuuut Beep/batteries Almost empty

Batt. low beep/radio Tut

Quick reference guide handset Gigaset 2000C Tango

Quick reference guide handset Gigaset 2000C Tango

KAP19.FM5

Index

Emergency numbers

Factory defaults

Handset Collective call

Lock

Signaling method

Settings

Setting Pause length according analog trunk/MSI

Setting

Siemens Aktiengesellschaft

KAP20.FM5