Instruction Manual

7.INSTALLATION

7.1 Sensor Locations

Select locations for each of the sensors based on the following:

-Consider the density of the gas to determine height of sensor above floor or ground level.

-Sensors should be placed close to the potential source of gas.

-Sensors should be placed in areas accessible for calibration.

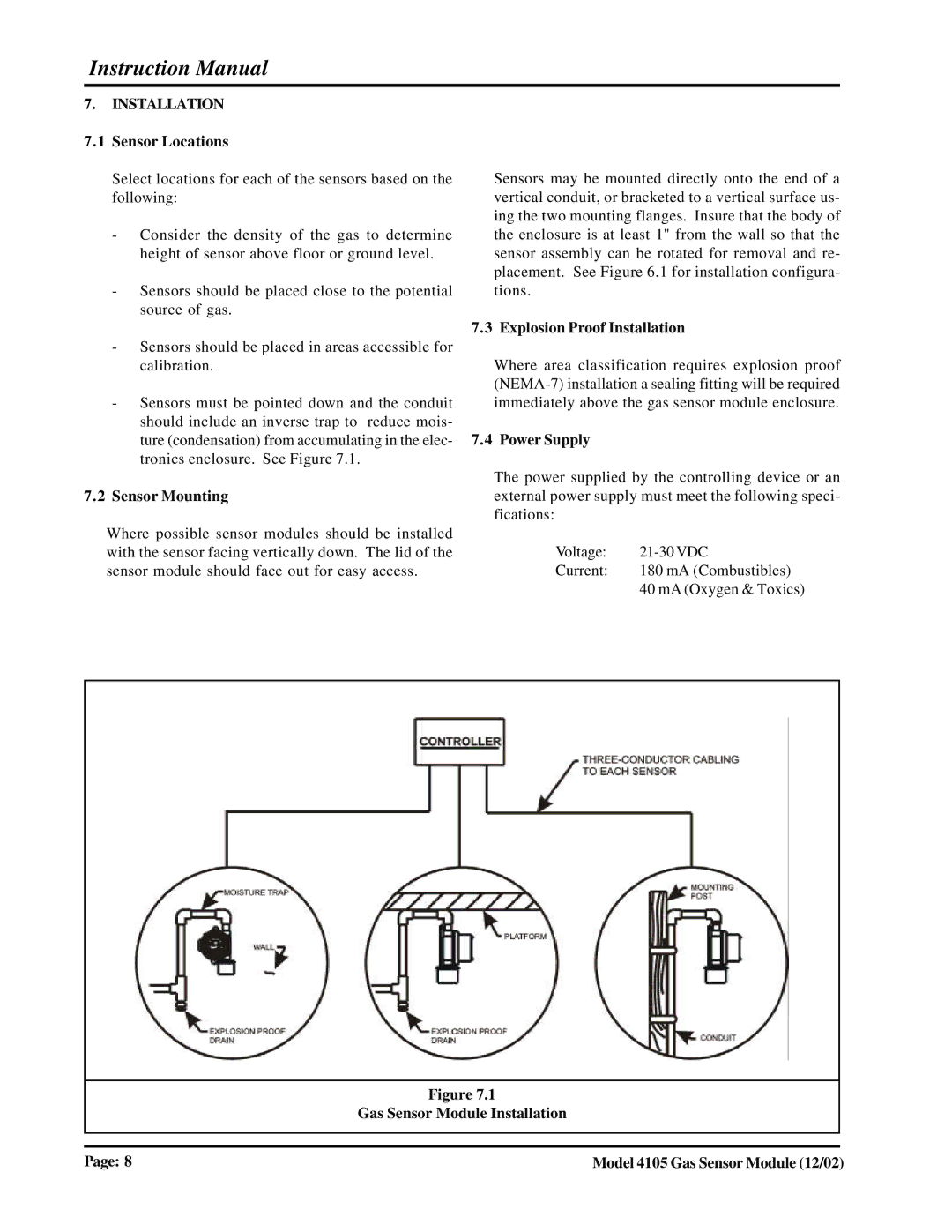

-Sensors must be pointed down and the conduit should include an inverse trap to reduce mois- ture (condensation) from accumulating in the elec- tronics enclosure. See Figure 7.1.

7.2Sensor Mounting

Where possible sensor modules should be installed with the sensor facing vertically down. The lid of the sensor module should face out for easy access.

Sensors may be mounted directly onto the end of a vertical conduit, or bracketed to a vertical surface us- ing the two mounting flanges. Insure that the body of the enclosure is at least 1" from the wall so that the sensor assembly can be rotated for removal and re- placement. See Figure 6.1 for installation configura- tions.

7.3 Explosion Proof Installation

Where area classification requires explosion proof

7.4 Power Supply

The power supplied by the controlling device or an external power supply must meet the following speci- fications:

Voltage: | |

Current: | 180 mA (Combustibles) |

| 40 mA (Oxygen & Toxics) |

Figure 7.1

Gas Sensor Module Installation

Page: 8 | Model 4105 Gas Sensor Module (12/02) |