Electrical | 10 |

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]() Hazardous voltage. Can shock, burn, or kill. Connect ground wire before connecting power sup- ply wires. Use the wire size (including the ground wire) specified in the wiring chart. If possible, connect the pump to a separate branch circuit with no other appli- ances on it.

Hazardous voltage. Can shock, burn, or kill. Connect ground wire before connecting power sup- ply wires. Use the wire size (including the ground wire) specified in the wiring chart. If possible, connect the pump to a separate branch circuit with no other appli- ances on it.

Explosion hazard. Do not ground to a gas

supply line.

WIRING CONNECTIONS

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]() Fire hazard. Incorrect voltage can cause a fire or seriously damage the motor and voids the warran- ty. The supply voltage must be within ±10% of the motor nameplate voltage.

Fire hazard. Incorrect voltage can cause a fire or seriously damage the motor and voids the warran- ty. The supply voltage must be within ±10% of the motor nameplate voltage.

NOTICE:

Install, ground, wire, and maintain your pump in compli- ance with the National Electrical Code (NEC) or the Canadian Electrical Code (CEC), as applicable, and with all local codes and ordinances that apply. Consult your local building inspector for code information.

Connection Procedure:

Step 1. Connect the ground wire first as shown in Figure

14.The ground wire must be a solid copper wire at least as large as the power supply wires.

Step 2. There must be a solid metal connection between the pressure switch and the motor for motor grounding protection. If the pressure switch is not connected to the motor, connect the green ground screw in the switch to the green ground screw under the motor end cover. Use a solid copper wire at least as large as the power supply wires.

Step 3. Connect the ground wire to a grounded lead in a service panel, to a metal underground water pipe, to a metal well casing at least ten feet (3M) long, or to a ground electrode provided by the power company or the hydro authority.

Step 4. Connect the power supply wires to the pressure switch as shown in Figure 14.

You have just completed the wiring for your pump. Please go to Page 11 or 12 for startup preparations.

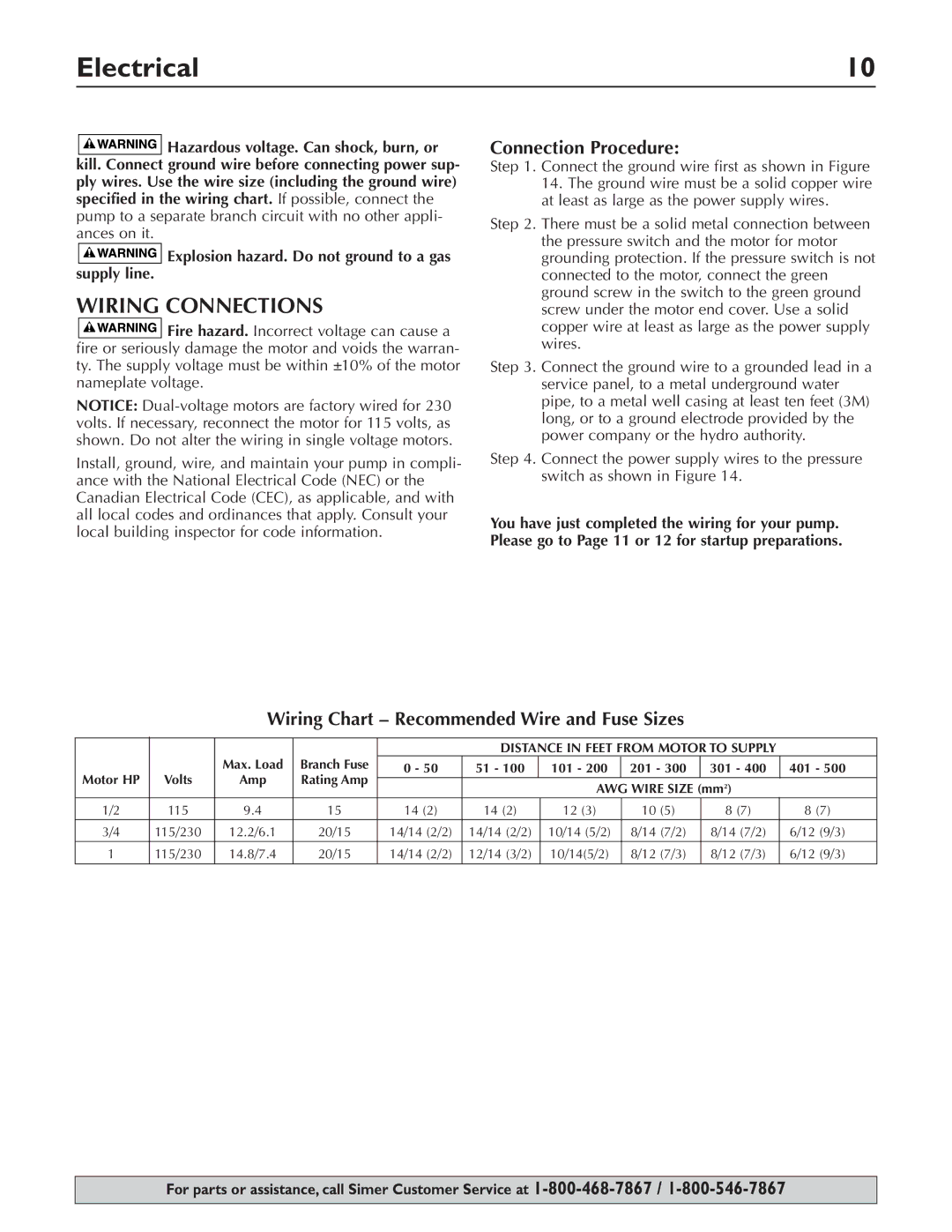

Wiring Chart – Recommended Wire and Fuse Sizes

|

|

|

|

| DISTANCE IN FEET FROM MOTOR TO SUPPLY |

| |||||

|

| Max. Load | Branch Fuse | 0 - 50 | 51 - 100 | 101 - 200 | 201 - 300 | 301 - 400 | 401 - 500 | ||

Motor HP | Volts | Amp | Rating Amp |

|

|

|

|

|

|

|

|

|

|

| AWG WIRE SIZE (mm2) |

| |||||||

|

|

|

|

|

|

|

| ||||

1/2 | 115 | 9.4 | 15 | 14 (2) | 14 (2) |

| 12 (3) | 10 | (5) | 8 (7) | 8 (7) |

3/4 | 115/230 | 12.2/6.1 | 20/15 | 14/14 (2/2) | 14/14 (2/2) |

| 10/14 (5/2) | 8/14 | (7/2) | 8/14 (7/2) | 6/12 (9/3) |

1 | 115/230 | 14.8/7.4 | 20/15 | 14/14 (2/2) | 12/14 (3/2) |

| 10/14(5/2) | 8/12 | (7/3) | 8/12 (7/3) | 6/12 (9/3) |

For parts or assistance, call Simer Customer Service at