Troubleshooting | 13 | |||||

|

|

|

|

|

| |

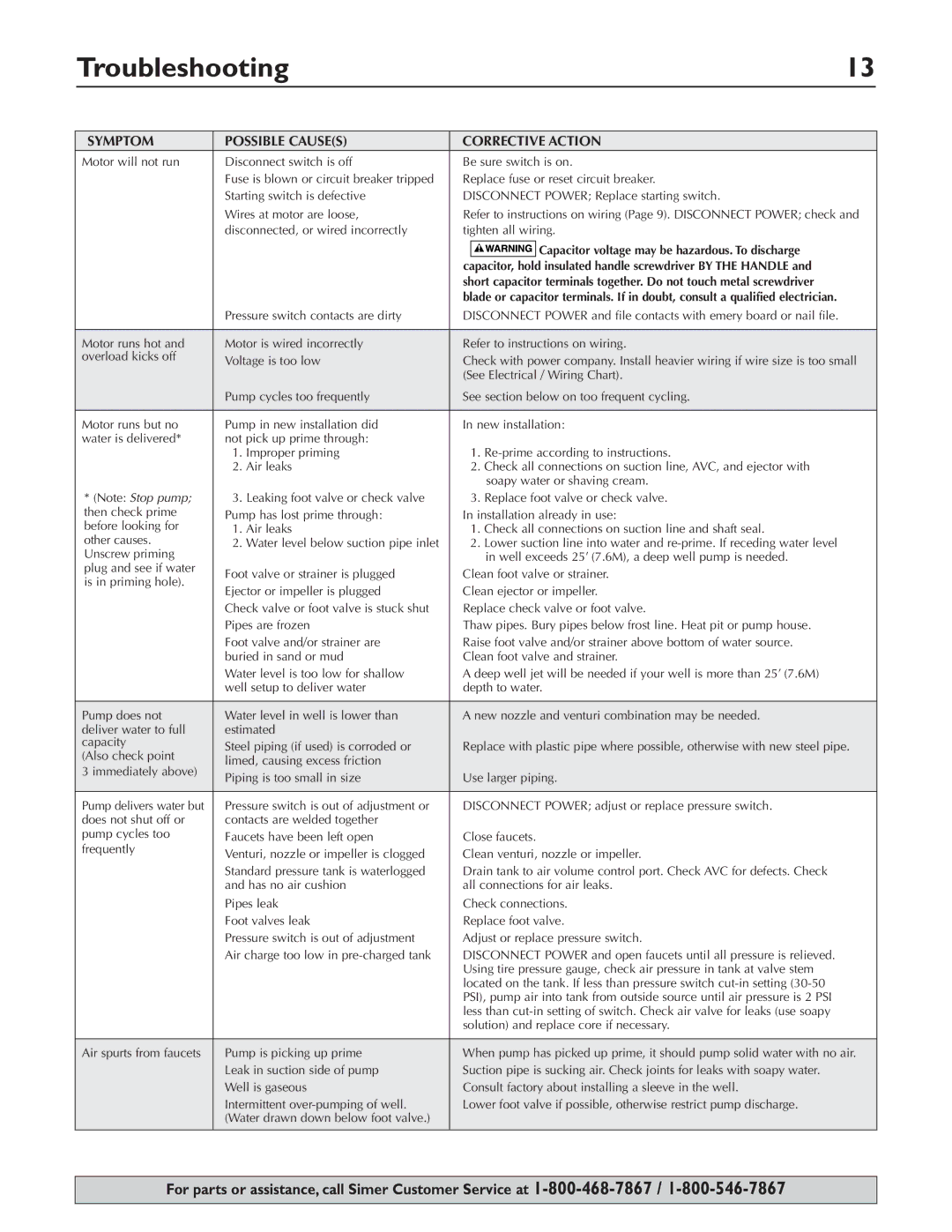

SYMPTOM | POSSIBLE CAUSE(S) | CORRECTIVE ACTION | ||||

Motor will not run | Disconnect switch is off | Be sure switch is on. | ||||

| Fuse is blown or circuit breaker tripped | Replace fuse or reset circuit breaker. | ||||

| Starting switch is defective | DISCONNECT POWER; Replace starting switch. | ||||

| Wires at motor are loose, | Refer to instructions on wiring (Page 9). DISCONNECT POWER; check and | ||||

| disconnected, or wired incorrectly | tighten all wiring. | ||||

|

|

|

|

| Capacitor voltage may be hazardous. To discharge | |

|

|

|

|

| ||

|

|

|

| |||

|

| capacitor, hold insulated handle screwdriver BY THE HANDLE and | ||||

|

| short capacitor terminals together. Do not touch metal screwdriver | ||||

|

| blade or capacitor terminals. If in doubt, consult a qualified electrician. | ||||

| Pressure switch contacts are dirty | DISCONNECT POWER and file contacts with emery board or nail file. | ||||

|

|

|

|

|

| |

Motor runs hot and | Motor is wired incorrectly | Refer to instructions on wiring. | ||||

overload kicks off | Voltage is too low | Check with power company. Install heavier wiring if wire size is too small | ||||

| ||||||

|

| (See Electrical / Wiring Chart). | ||||

| Pump cycles too frequently | See section below on too frequent cycling. | ||||

|

|

|

|

|

| |

Motor runs but no | Pump in new installation did | In new installation: | ||||

water is delivered* | not pick up prime through: |

|

|

|

| |

| 1. Improper priming | 1. | ||||

| 2. Air leaks | 2. Check all connections on suction line, AVC, and ejector with | ||||

|

|

| soapy water or shaving cream. | |||

* (Note: Stop pump; | 3. Leaking foot valve or check valve | 3. Replace foot valve or check valve. | ||||

then check prime | Pump has lost prime through: | In installation already in use: | ||||

before looking for | 1. Air leaks | 1. Check all connections on suction line and shaft seal. | ||||

other causes. | 2. Water level below suction pipe inlet | 2. Lower suction line into water and | ||||

Unscrew priming |

|

| in well exceeds 25’ (7.6M), a deep well pump is needed. | |||

plug and see if water | Foot valve or strainer is plugged | Clean foot valve or strainer. | ||||

is in priming hole). | ||||||

Ejector or impeller is plugged | Clean ejector or impeller. | |||||

| ||||||

| Check valve or foot valve is stuck shut | Replace check valve or foot valve. | ||||

| Pipes are frozen | Thaw pipes. Bury pipes below frost line. Heat pit or pump house. | ||||

| Foot valve and/or strainer are | Raise foot valve and/or strainer above bottom of water source. | ||||

| buried in sand or mud | Clean foot valve and strainer. | ||||

| Water level is too low for shallow | A deep well jet will be needed if your well is more than 25’ (7.6M) | ||||

| well setup to deliver water | depth to water. | ||||

|

|

|

|

|

| |

Pump does not | Water level in well is lower than | A new nozzle and venturi combination may be needed. | ||||

deliver water to full | estimated |

|

|

|

| |

capacity | Steel piping (if used) is corroded or | Replace with plastic pipe where possible, otherwise with new steel pipe. | ||||

(Also check point | ||||||

limed, causing excess friction |

|

|

|

| ||

3 immediately above) |

|

|

|

| ||

Piping is too small in size | Use larger piping. | |||||

| ||||||

|

|

|

|

|

| |

Pump delivers water but | Pressure switch is out of adjustment or | DISCONNECT POWER; adjust or replace pressure switch. | ||||

does not shut off or | contacts are welded together |

|

|

|

| |

pump cycles too | Faucets have been left open | Close faucets. | ||||

frequently | Venturi, nozzle or impeller is clogged | Clean venturi, nozzle or impeller. | ||||

| ||||||

| Standard pressure tank is waterlogged | Drain tank to air volume control port. Check AVC for defects. Check | ||||

| and has no air cushion | all connections for air leaks. | ||||

| Pipes leak | Check connections. | ||||

| Foot valves leak | Replace foot valve. | ||||

| Pressure switch is out of adjustment | Adjust or replace pressure switch. | ||||

| Air charge too low in | DISCONNECT POWER and open faucets until all pressure is relieved. | ||||

|

| Using tire pressure gauge, check air pressure in tank at valve stem | ||||

|

| located on the tank. If less than pressure switch | ||||

|

| PSI), pump air into tank from outside source until air pressure is 2 PSI | ||||

|

| less than | ||||

|

| solution) and replace core if necessary. | ||||

|

|

|

|

|

| |

Air spurts from faucets | Pump is picking up prime | When pump has picked up prime, it should pump solid water with no air. | ||||

| Leak in suction side of pump | Suction pipe is sucking air. Check joints for leaks with soapy water. | ||||

| Well is gaseous | Consult factory about installing a sleeve in the well. | ||||

| Intermittent | Lower foot valve if possible, otherwise restrict pump discharge. | ||||

| (Water drawn down below foot valve.) |

|

|

|

| |

|

|

|

|

|

| |

For parts or assistance, call Simer Customer Service at