Adjustments

Aligning Rip Fence

! | WARNING | To prevent personal injury, always disconnect | |

plug from power source before making any | |||

|

|

adjustments.

The rip fence must be parallel with the SAWBLADE in order to prevent KICKBACK when ripping.

Your table saw is equipped with a

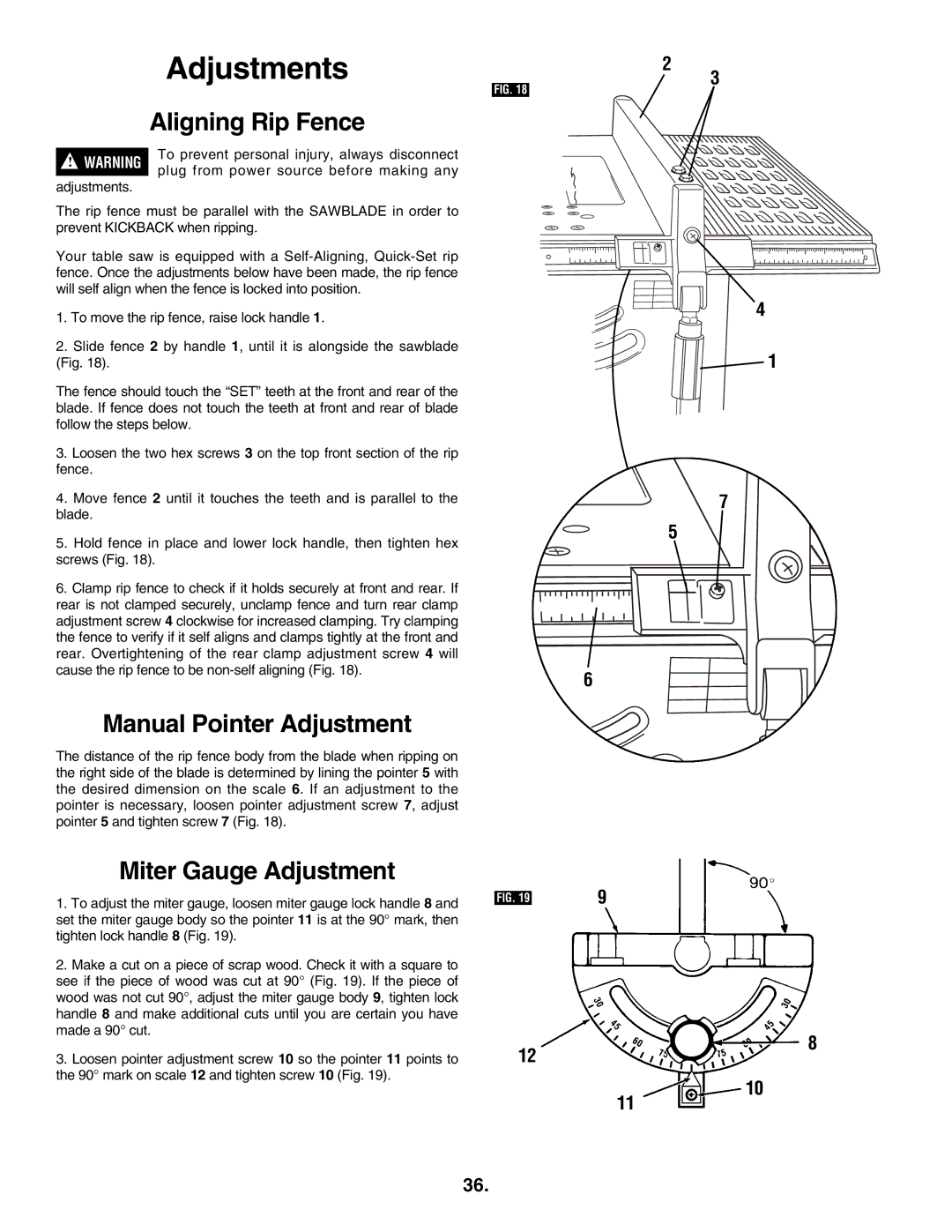

1.To move the rip fence, raise lock handle 1.

2.Slide fence 2 by handle 1, until it is alongside the sawblade (Fig. 18).

The fence should touch the “SET” teeth at the front and rear of the blade. If fence does not touch the teeth at front and rear of blade follow the steps below.

3.Loosen the two hex screws 3 on the top front section of the rip fence.

4.Move fence 2 until it touches the teeth and is parallel to the blade.

5.Hold fence in place and lower lock handle, then tighten hex screws (Fig. 18).

6.Clamp rip fence to check if it holds securely at front and rear. If rear is not clamped securely, unclamp fence and turn rear clamp adjustment screw 4 clockwise for increased clamping. Try clamping the fence to verify if it self aligns and clamps tightly at the front and rear. Overtightening of the rear clamp adjustment screw 4 will cause the rip fence to be

Manual Pointer Adjustment

The distance of the rip fence body from the blade when ripping on the right side of the blade is determined by lining the pointer 5 with the desired dimension on the scale 6. If an adjustment to the pointer is necessary, loosen pointer adjustment screw 7, adjust pointer 5 and tighten screw 7 (Fig. 18).

Miter Gauge Adjustment

1. To adjust the miter gauge, loosen miter gauge lock handle 8 and |

set the miter gauge body so the pointer 11 is at the 90° mark, then |

tighten lock handle 8 (Fig. 19). |

2. Make a cut on a piece of scrap wood. Check it with a square to |

see if the piece of wood was cut at 90° (Fig. 19). If the piece of |

wood was not cut 90°, adjust the miter gauge body 9, tighten lock |

handle 8 and make additional cuts until you are certain you have |

made a 90° cut. |

2 ![]() 3

3

FIG. 18

|

|

|

|

|

|

|

| 23 |

|

|

|

|

|

|

0 |

| 1 |

|

|

|

|

|

|

|

| 10 |

| 11 |

|

1 | 2 | 3 | 4 | 2 | 2 | 21 | 22 | 24 | 2 | 2 | 2 | 2 | 2 | 30 |

4

![]() 1

1

7

5

01

1 2 3 4

6

| 9 |

FIG. 19 |

3. Loosen pointer adjustment screw 10 so the pointer 11 points to |

the 90° mark on scale 12 and tighten screw 10 (Fig. 19). |

12

8

10

11

36.