Blade Elevation and Tilting

Mechanism

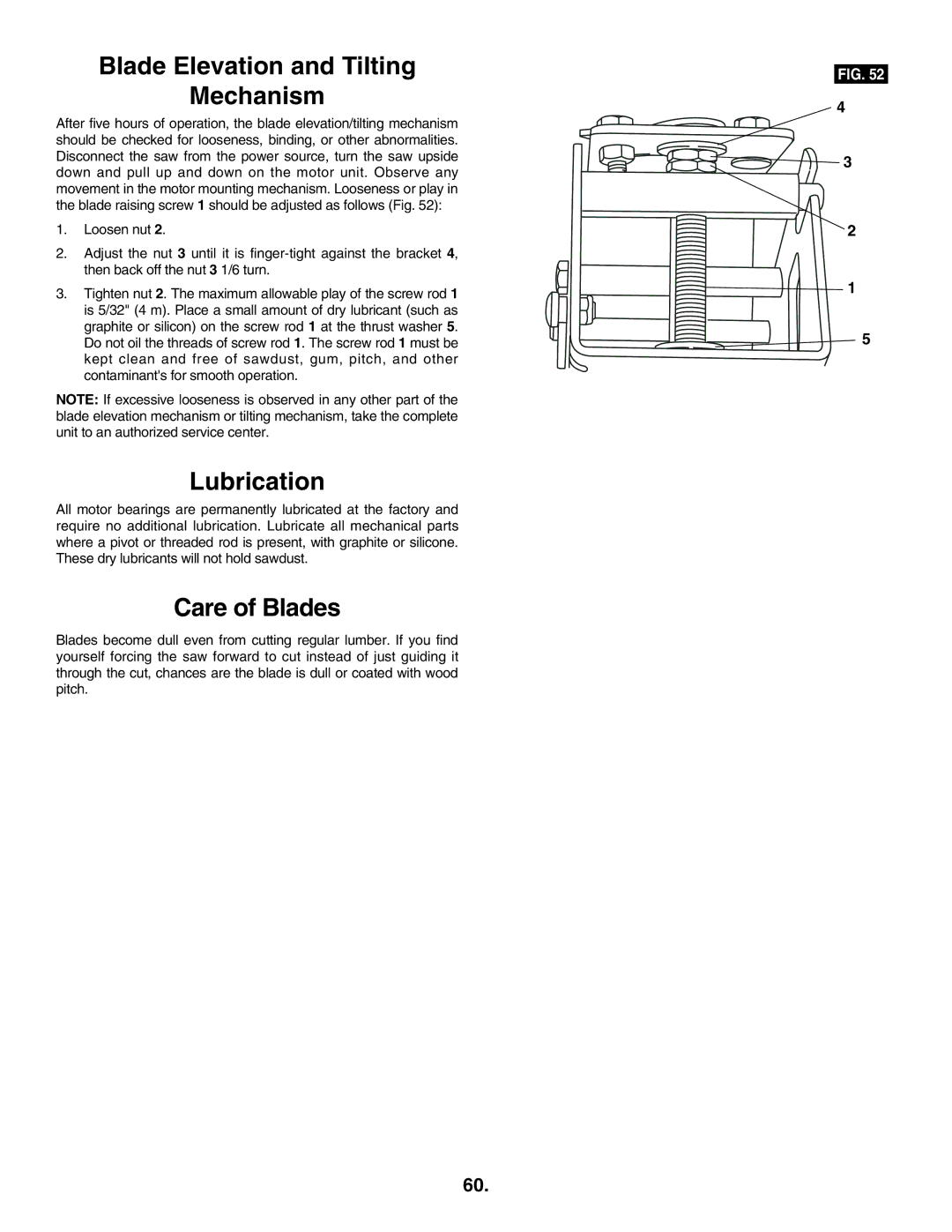

After five hours of operation, the blade elevation/tilting mechanism should be checked for looseness, binding, or other abnormalities. Disconnect the saw from the power source, turn the saw upside down and pull up and down on the motor unit. Observe any movement in the motor mounting mechanism. Looseness or play in the blade raising screw 1 should be adjusted as follows (Fig. 52):

1.Loosen nut 2.

2.Adjust the nut 3 until it is

3.Tighten nut 2. The maximum allowable play of the screw rod 1 is 5/32" (4 m). Place a small amount of dry lubricant (such as graphite or silicon) on the screw rod 1 at the thrust washer 5. Do not oil the threads of screw rod 1. The screw rod 1 must be kept clean and free of sawdust, gum, pitch, and other contaminant's for smooth operation.

NOTE: If excessive looseness is observed in any other part of the blade elevation mechanism or tilting mechanism, take the complete unit to an authorized service center.

Lubrication

All motor bearings are permanently lubricated at the factory and require no additional lubrication. Lubricate all mechanical parts where a pivot or threaded rod is present, with graphite or silicone. These dry lubricants will not hold sawdust.

Care of Blades

Blades become dull even from cutting regular lumber. If you find yourself forcing the saw forward to cut instead of just guiding it through the cut, chances are the blade is dull or coated with wood pitch.

FIG. 52

4

![]() 3

3

2

![]() 1

1

![]() 5

5

60.