SM 2610957121

Basic Scroll Saw Operations

Recommendations for cutting

A scroll saw is basically a

1.When feeding the workpiece into the blade do not force it against the blade. This could cause blade deflec- tion. Allow the saw to cut the material by guiding the workpiece into the blade as it cuts.

2.The blade teeth cut material ONLY on the down stroke.

3.Guide the wood into the blade slowly because the teeth of the blade are very small and remove wood only on the down stroke.

4.There is a learning curve for each person using this saw. During that period of time it is expected that some blades will break until you learn how to use the saw.

5.Best results are achieved when cutting wood one inch thick or less.

6.When cutting wood thicker than one inch, guide the wood very, very slowly into the blade and take extra care not to bend or twist the blade while cutting in order to maximize blade life.

7.Teeth on scroll saw blades wear out and the blades must be replaced frequently for best cutting results. Scroll saw blades generally stay sharp for 1/2 hour to 2 hours of cutting.

8.To get accurate cuts, be prepared to compensate for the blade's tendency to follow the wood grain as you are cutting.

9.This scroll saw is primarily designed to cut wood or wood products. For cutting precious and

10.When choosing a blade, use very fine, narrow blades to scroll cut in thin wood 1/4" thick or less. Use wider blades for thicker materials but this will reduce the ability to cut tight curves.

11.Blades wear faster when cutting plywood or very abrasive particle board. Angle cutting in hardwoods wears blades down faster.

12.Always use the foot to keep workpiece against table. It must be set just above the workpiece for free scrolling allowance, leaving no more than a gap of 1/16 inch between the foot and workpiece.

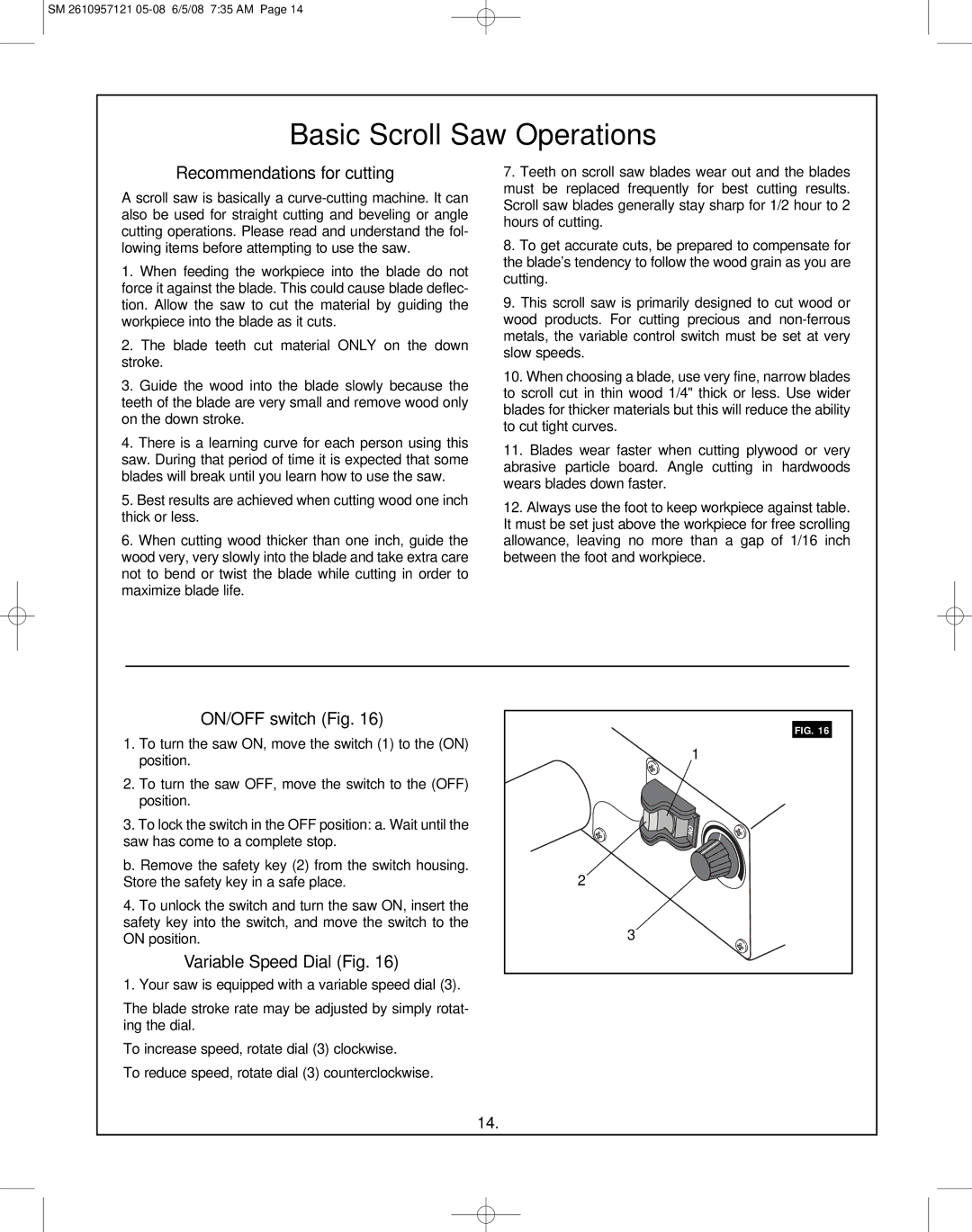

ON/OFF switch (Fig. 16)

1.To turn the saw ON, move the switch (1) to the (ON) position.

2.To turn the saw OFF, move the switch to the (OFF) position.

3.To lock the switch in the OFF position: a. Wait until the saw has come to a complete stop.

b. Remove the safety key (2) from the switch housing. Store the safety key in a safe place.

4.To unlock the switch and turn the saw ON, insert the safety key into the switch, and move the switch to the ON position.

Variable Speed Dial (Fig. 16)

1. Your saw is equipped with a variable speed dial (3).

The blade stroke rate may be adjusted by simply rotat- ing the dial.

To increase speed, rotate dial (3) clockwise.

To reduce speed, rotate dial (3) counterclockwise.

FIG. 16

1

2

3

14.