SM 2610957121

Assembly and adjustments

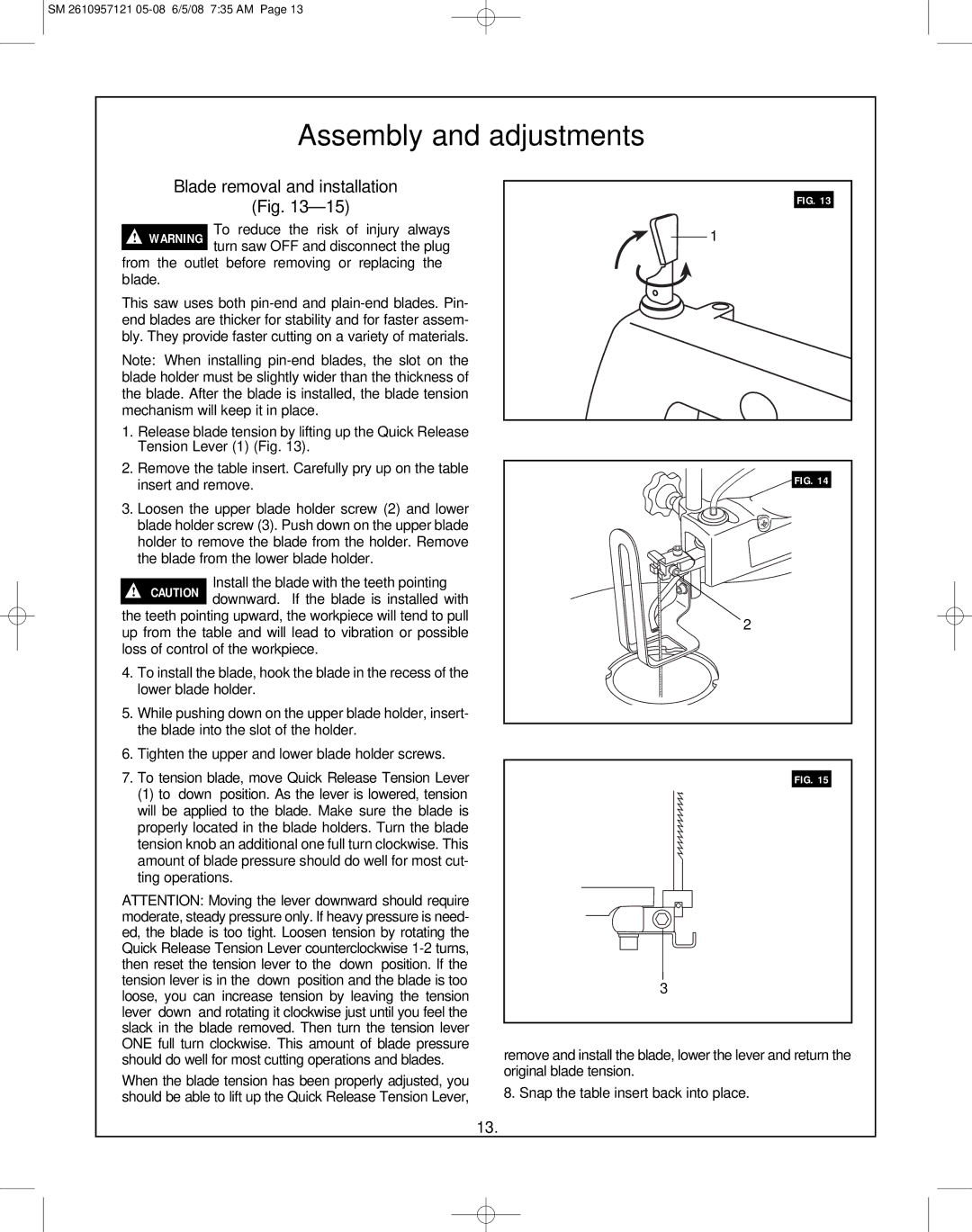

Blade removal and installation (Fig. 13–15)

To reduce the risk of injury always ! WARNING turn saw OFF and disconnect the plug

from the outlet before removing or replacing the blade.

This saw uses both

Note: When installing

1.Release blade tension by lifting up the Quick Release Tension Lever (1) (Fig. 13).

2.Remove the table insert. Carefully pry up on the table insert and remove.

3.Loosen the upper blade holder screw (2) and lower blade holder screw (3). Push down on the upper blade holder to remove the blade from the holder. Remove the blade from the lower blade holder.

Install the blade with the teeth pointing ! CAUTION downward. If the blade is installed with

the teeth pointing upward, the workpiece will tend to pull up from the table and will lead to vibration or possible loss of control of the workpiece.

4. To install the blade, hook the blade in the recess of the lower blade holder.

5. While pushing down on the upper blade holder, insert- the blade into the slot of the holder.

6. Tighten the upper and lower blade holder screws.

7. To tension blade, move Quick Release Tension Lever

(1) to “down” position. As the lever is lowered, tension will be applied to the blade. Make sure the blade is properly located in the blade holders. Turn the blade tension knob an additional one full turn clockwise. This amount of blade pressure should do well for most cut- ting operations.

ATTENTION: Moving the lever downward should require moderate, steady pressure only. If heavy pressure is need- ed, the blade is too tight. Loosen tension by rotating the Quick Release Tension Lever counterclockwise

When the blade tension has been properly adjusted, you should be able to lift up the Quick Release Tension Lever,

FIG. 13

1

FIG. 14

2

FIG. 15

3

remove and install the blade, lower the lever and return the original blade tension.

8. Snap the table insert back into place.

13.