Gauge Wheels (Select Models)

The mower gauge wheels can be placed in several posi- tions depending on the height of cut. When using higher cutting heights, set the wheels in the lower position.

When using lower cutting heights, set the wheels in the upper position. To adjust:

PIVOTING GAUGE WHEELS

1.Remove the hair pin clip (A, B, Figure 46).

2.For upper position, install the pin (A) through the spindle above the bracket (C). For the lower position, push down on the top of the spindle, and install the hair pin clip (B) below the top of the bracket (C).

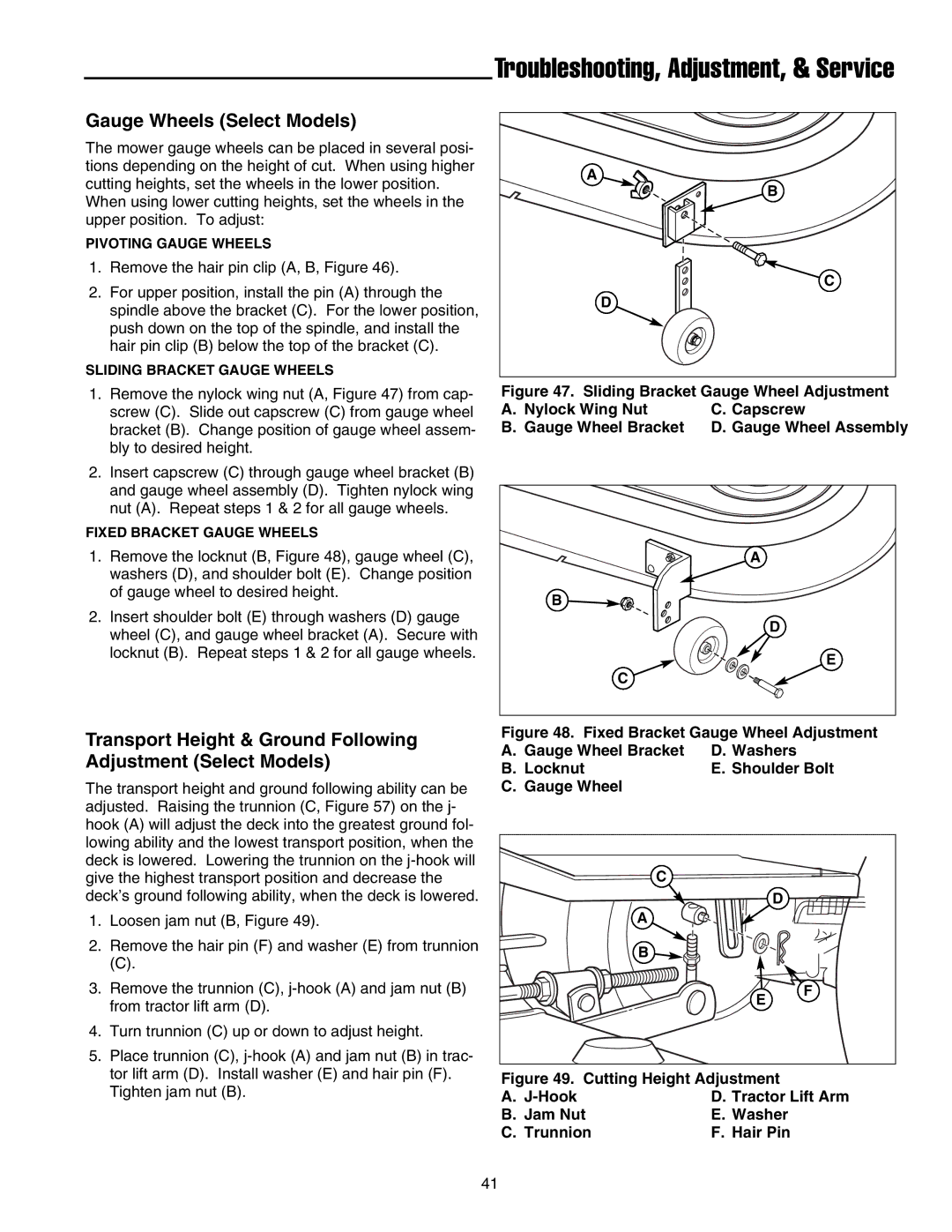

SLIDING BRACKET GAUGE WHEELS

1.Remove the nylock wing nut (A, Figure 47) from cap- screw (C). Slide out capscrew (C) from gauge wheel bracket (B). Change position of gauge wheel assem- bly to desired height.

2.Insert capscrew (C) through gauge wheel bracket (B) and gauge wheel assembly (D). Tighten nylock wing nut (A). Repeat steps 1 & 2 for all gauge wheels.

FIXED BRACKET GAUGE WHEELS

1.Remove the locknut (B, Figure 48), gauge wheel (C), washers (D), and shoulder bolt (E). Change position of gauge wheel to desired height.

2.Insert shoulder bolt (E) through washers (D) gauge wheel (C), and gauge wheel bracket (A). Secure with locknut (B). Repeat steps 1 & 2 for all gauge wheels.

Transport Height & Ground Following Adjustment (Select Models)

The transport height and ground following ability can be adjusted. Raising the trunnion (C, Figure 57) on the j- hook (A) will adjust the deck into the greatest ground fol- lowing ability and the lowest transport position, when the deck is lowered. Lowering the trunnion on the

1.Loosen jam nut (B, Figure 49).

2.Remove the hair pin (F) and washer (E) from trunnion

(C).

3.Remove the trunnion (C),

4.Turn trunnion (C) up or down to adjust height.

5.Place trunnion (C),

Troubleshooting, Adjustment, & Service

A |

B |

C |

D |

Figure 47. Sliding Bracket Gauge Wheel Adjustment

A. | Nylock Wing Nut | C. Capscrew |

B. | Gauge Wheel Bracket | D. Gauge Wheel Assembly |

A

B

D |

E

C

Figure 48. Fixed Bracket Gauge Wheel Adjustment

A. Gauge Wheel Bracket | D. Washers |

B. Locknut | E. Shoulder Bolt |

C. Gauge Wheel |

|

C |

|

| D |

A |

|

B |

|

E | F |

|

Figure 49. Cutting Height Adjustment

A. | D. Tractor Lift Arm |

B. Jam Nut | E. Washer |

C. Trunnion | F. Hair Pin |

41