SECTION 3 - OPERATING INSTRUCTIONS

3.3 PRE-START CHECK LIST

Make the following checks and perform the services as required before each

1.If required, make cutting height adjustments. Refer to Section "CUTTING HEIGHT ADJUSTMENT".

2, Check tires and add air as needed to bring pressure to 25 psi in front and

3.Check Guards, Deflector, and Belt Covers to make sure all are in place and secure.

4.Check Condition of Cutter Deck Belt(s). If dam- aged, replace before operating machine. Refer to Section "CUTTER DECK BELT REMOVAL".

5.Clean Interior and Exterior Surfaces of cutting deck and clean Engine of any accumulation of dirt, grass,

oil, etc. Keep Engine air intake screens and cooling fins clear at all times.

6.Check Engine Oil and add oil as needed to bring level up to (but not over) the FULL mark. (Refer to Engine manual for oil specifications).

7.Add Fuel to tank after pushing the Mower outside where fumes can be dissipated. Make sure Fuel Tank Cap is tightened after refueling. (Refer to Engine manual for fuel specifications).

NOTE: DO NOT add fuel while engine is running or hot. Use fresh, clean,

3.4 STARTING & OPERATING

3.4.1. ENGINE: START ENGINE AS FOLLOWS:

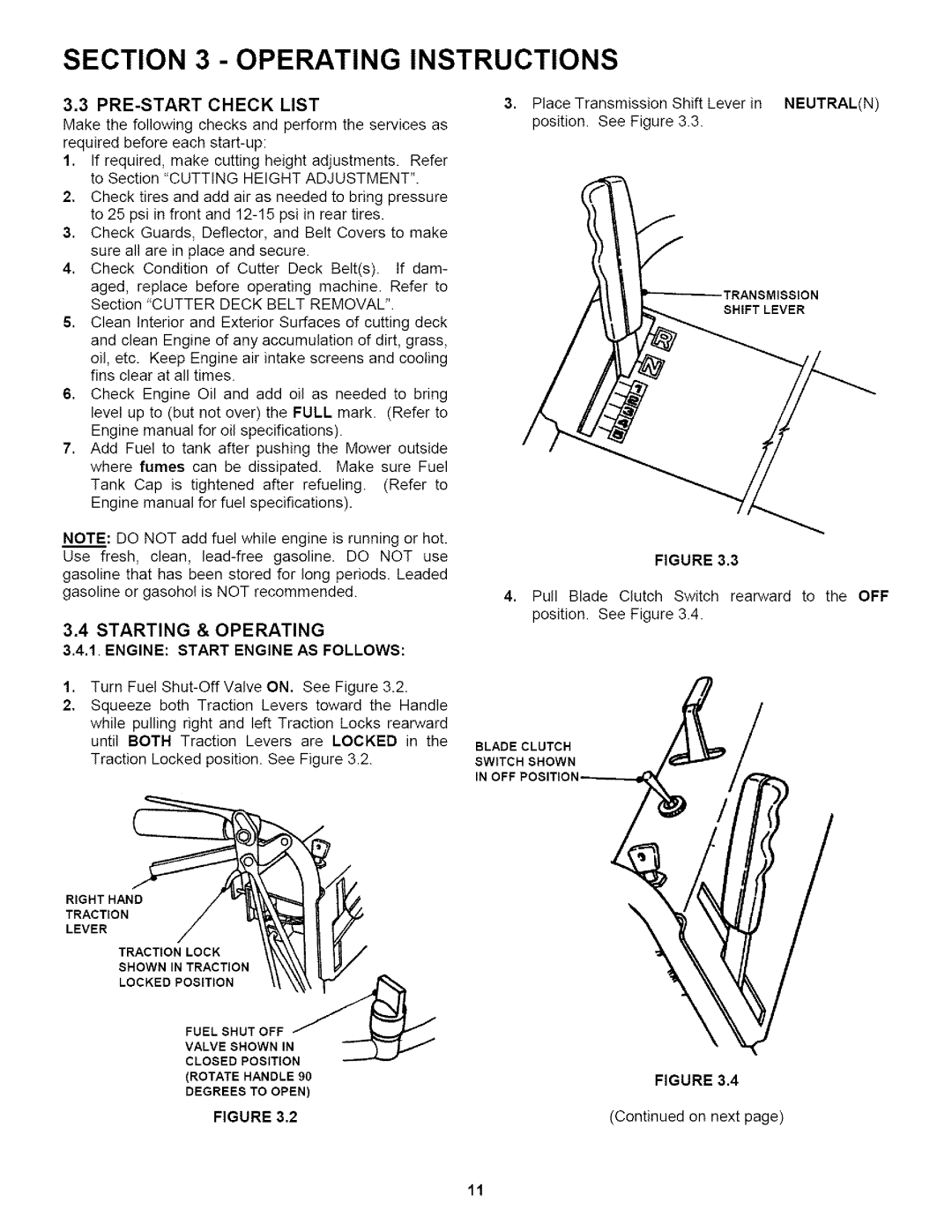

1, Turn Fuel

2, Squeeze both Traction Levers toward the Handle

while pulling right and left Traction Locks rearward until BOTH Traction Levers are LOCKED in the

Traction Locked position. See Figure 3.2.

RIGHT HAND

TRACTION

LEVER

TRACTION LOCK

SHOWN IN TRACTION

LOCKED POSITION

FUEL SHUT OFF

VALVE SHOWNIN

CLOSED POSITION

(ROTATE HANDLE 90

DEGREES TO OPEN)

FIGURE 3.2

3.Place Transmission Shift Lever in NEUTRAL(N) position. See Figure 3.3.

TRANSMISSION

SHIFT LEVER

FIGURE 3.3

4.Pull Blade Clutch Switch rearward to the OFF position. See Figure 3.4.

BLADE CLUTCH

SWITCH SHOWN

IN OFF

FIGURE 3.4

(Continued on next page)

11