Section 4 - MAINTENANCE

4.3.3. RIDING MOWER - LUBRICATION | 3. Power Transfer Shaft |

1. Front & Rear Wheel Bearings | Lubricate power transfer shaft with Kendall NLGI |

Lubricate with Kendall NLGI No. 2 lithium grease or | No. 2 lithium grease or equivalent, from a grease |

equivalent, from a grease gun. See Figure 4.5. | gun. See Figure 4.7. |

LUBRICATE

BEARINGS

FRONT

WHEEL

FIGURE 4.5

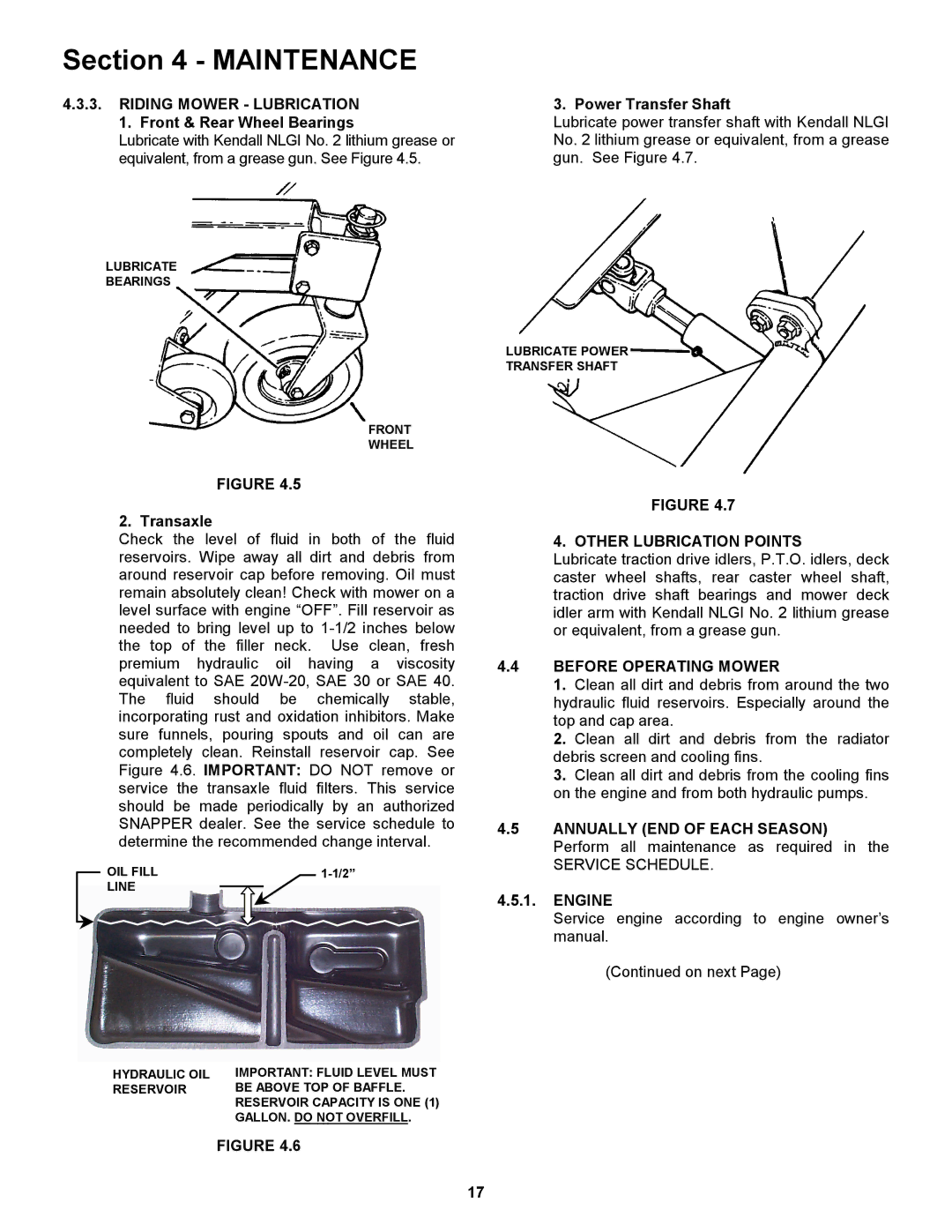

2. Transaxle

Check the level of fluid in both of the fluid reservoirs. Wipe away all dirt and debris from around reservoir cap before removing. Oil must remain absolutely clean! Check with mower on a level surface with engine “OFF”. Fill reservoir as needed to bring level up to

OIL FILL |

| |

LINE |

|

|

|

|

HYDRAULIC OIL | IMPORTANT: FLUID LEVEL MUST |

RESERVOIR | BE ABOVE TOP OF BAFFLE. |

| RESERVOIR CAPACITY IS ONE (1) |

| GALLON. DO NOT OVERFILL. |

FIGURE 4.6

LUBRICATE POWER

TRANSFER SHAFT

FIGURE 4.7

4. OTHER LUBRICATION POINTS

Lubricate traction drive idlers, P.T.O. idlers, deck caster wheel shafts, rear caster wheel shaft, traction drive shaft bearings and mower deck idler arm with Kendall NLGI No. 2 lithium grease or equivalent, from a grease gun.

4.4BEFORE OPERATING MOWER

1.Clean all dirt and debris from around the two hydraulic fluid reservoirs. Especially around the top and cap area.

2.Clean all dirt and debris from the radiator debris screen and cooling fins.

3.Clean all dirt and debris from the cooling fins on the engine and from both hydraulic pumps.

4.5ANNUALLY (END OF EACH SEASON) Perform all maintenance as required in the

SERVICE SCHEDULE.

4.5.1.ENGINE

Service engine according to engine owner’s manual.

(Continued on next Page)

17