[ G BOARD]

KP-43T75A/53SV75A

SECTION 4

SAFETY RELATED ADJUSTMENTS

4-1. HV REGULATION CIRCUIT CHECK AND ADJUSTMENT

When replacing the following components marked with ![]()

on the schematic diagram always check HV regulation, and if necessary

![]()

![]() : C517

: C517

![]() : C517, C521, C522

: C517, C521, C522

IC654, L504

T502, T504 (FBT)

D.Y, A board, G board

OPERATION CHECK

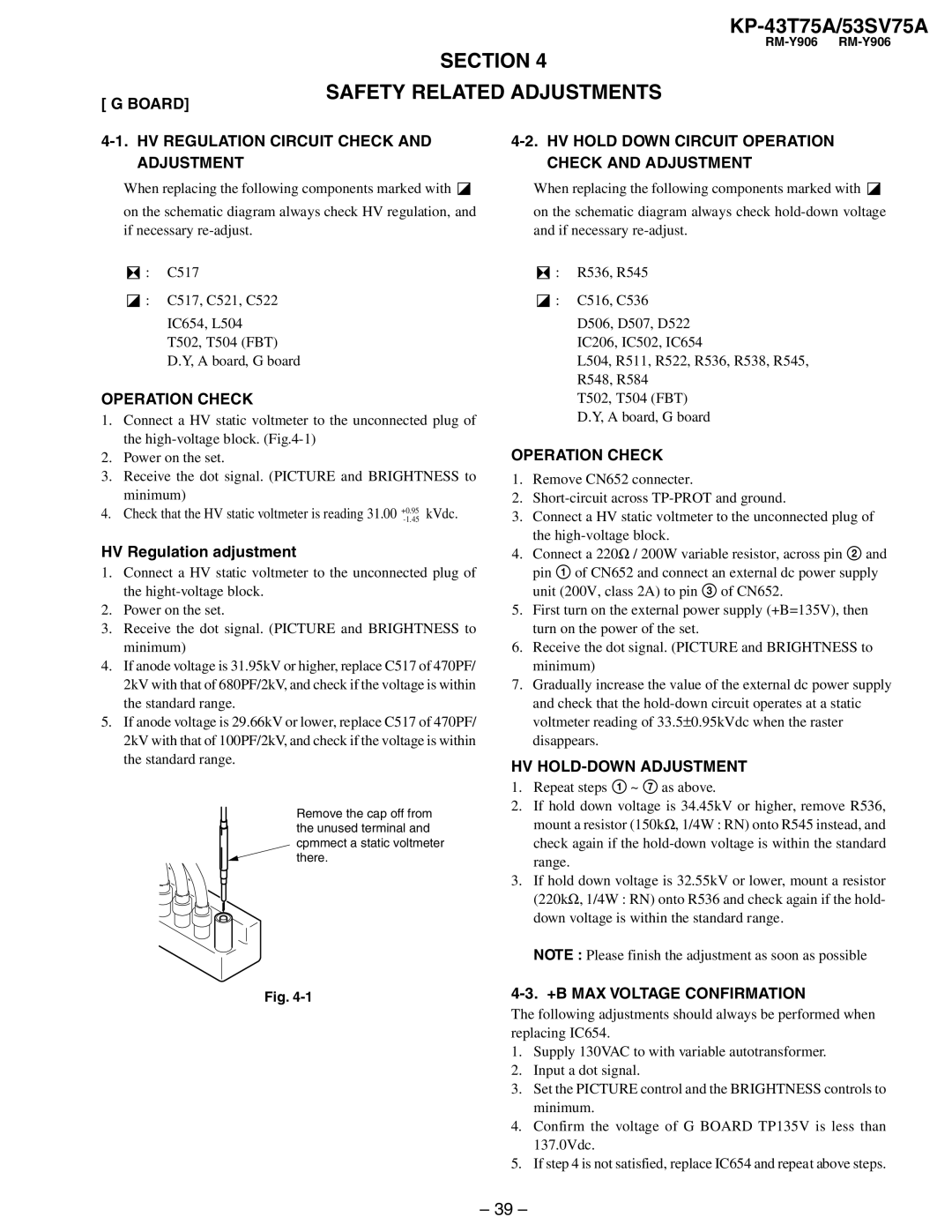

1. Connect a HV static voltmeter to the unconnected plug of the

2. Power on the set.

3. Receive the dot signal. (PICTURE and BRIGHTNESS to minimum)

4. Check that the HV static voltmeter is reading 31.00 +0.95 kVdc.

HV Regulation adjustment

1.Connect a HV static voltmeter to the unconnected plug of the

2.Power on the set.

3.Receive the dot signal. (PICTURE and BRIGHTNESS to minimum)

4.If anode voltage is 31.95kV or higher, replace C517 of 470PF/ 2kV with that of 680PF/2kV, and check if the voltage is within the standard range.

5.If anode voltage is 29.66kV or lower, replace C517 of 470PF/ 2kV with that of 100PF/2kV, and check if the voltage is within the standard range.

Remove the cap off from the unused terminal and cpmmect a static voltmeter there.

Fig.

4-2. HV HOLD DOWN CIRCUIT OPERATION CHECK AND ADJUSTMENT

When replacing the following components marked with ![]()

on the schematic diagram always check

![]()

![]() : R536, R545

: R536, R545

![]() : C516, C536

: C516, C536

D506, D507, D522

IC206, IC502, IC654

L504, R511, R522, R536, R538, R545,

R548, R584

T502, T504 (FBT)

D.Y, A board, G board

OPERATION CHECK

1.Remove CN652 connecter.

2.

3.Connect a HV static voltmeter to the unconnected plug of the

4.Connect a 220Ω / 200W variable resistor, across pin 2 and pin 1 of CN652 and connect an external dc power supply unit (200V, class 2A) to pin 3 of CN652.

5.First turn on the external power supply (+B=135V), then turn on the power of the set.

6.Receive the dot signal. (PICTURE and BRIGHTNESS to minimum)

7.Gradually increase the value of the external dc power supply

and check that the

disappears.

HV HOLD-DOWN ADJUSTMENT

1.Repeat steps 1 ~ 7 as above.

2.If hold down voltage is 34.45kV or higher, remove R536, mount a resistor (150kΩ , 1/4W : RN) onto R545 instead, and

check again if the

3.If hold down voltage is 32.55kV or lower, mount a resistor (220kΩ , 1/4W : RN) onto R536 and check again if the hold-

down voltage is within the standard range.

NOTE : Please finish the adjustment as soon as possible

4-3. +B MAX VOLTAGE CONFIRMATION

The following adjustments should always be performed when replacing IC654.

1.Supply 130VAC to with variable autotransformer.

2.Input a dot signal.

3.Set the PICTURE control and the BRIGHTNESS controls to minimum.

4.Confirm the voltage of G BOARD TP135V is less than 137.0Vdc.

5.If step 4 is not satisfied, replace IC654 and repeat above steps.

– 39 –