Installation

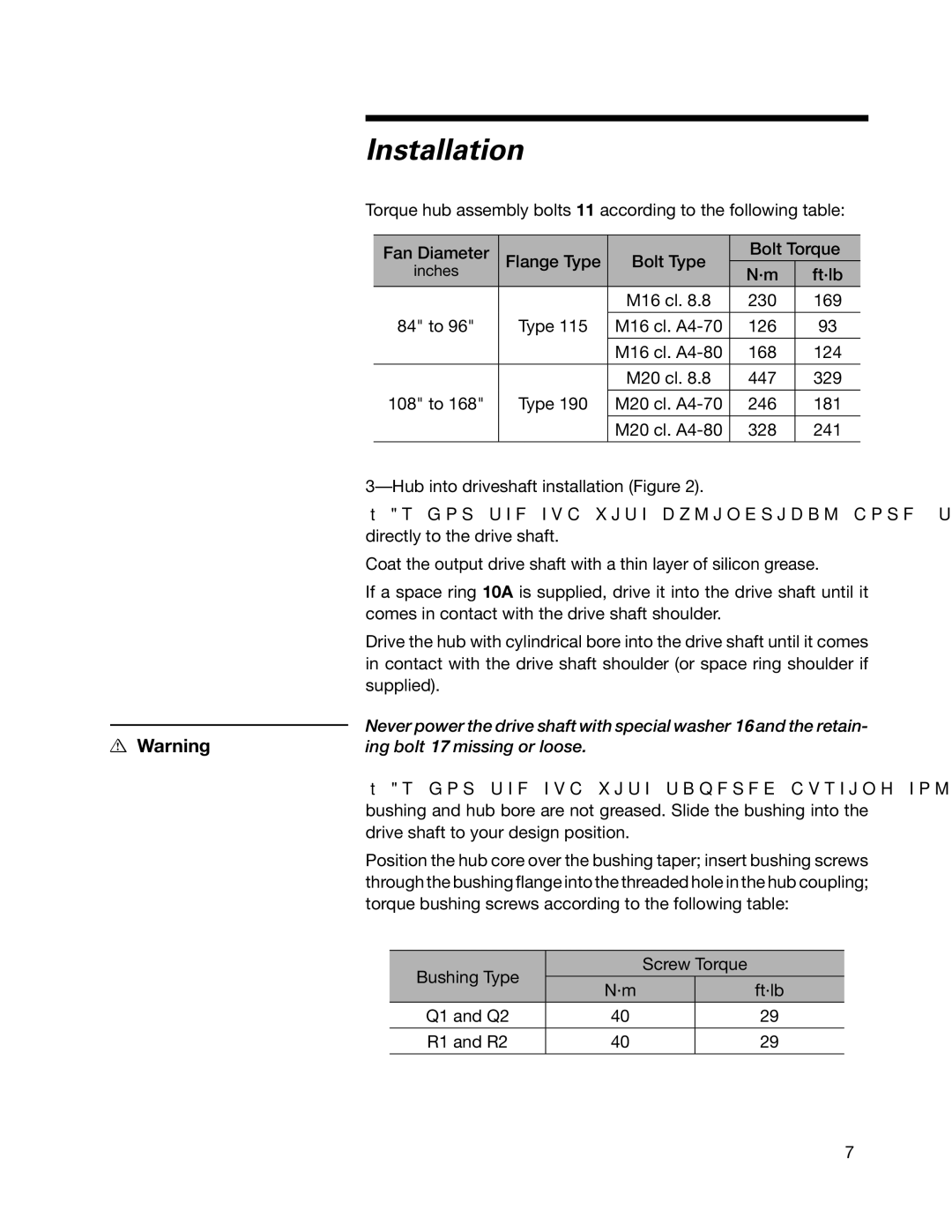

Torque hub assembly bolts 11 according to the following table:

Fan Diameter | Flange Type | Bolt Type | Bolt Torque | ||

|

| ||||

N·m | ft·lb | ||||

inches |

|

| |||

|

| M16 cl. 8.8 | 230 | 169 | |

|

|

|

|

| |

84" to 96" | Type 115 | M16 cl. | 126 | 93 | |

|

|

|

|

| |

|

| M16 cl. | 168 | 124 | |

|

|

|

|

| |

|

| M20 cl. 8.8 | 447 | 329 | |

|

|

|

|

| |

108" to 168" | Type 190 | M20 cl. | 246 | 181 | |

|

|

|

|

| |

|

| M20 cl. | 328 | 241 | |

|

|

|

|

| |

•As for the hub with cylindrical bore, the hub is bored to attach directly to the drive shaft.

Coat the output drive shaft with a thin layer of silicon grease.

If a space ring 10A is supplied, drive it into the drive shaft until it comes in contact with the drive shaft shoulder.

Drive the hub with cylindrical bore into the drive shaft until it comes in contact with the drive shaft shoulder (or space ring shoulder if supplied).

Warning | Never power the drive shaft with special washer 16 and the retain- |

ing bolt 17 missing or loose. |

•As for the hub with tapered bushing hole, be sure drive shaft, bushing and hub bore are not greased. Slide the bushing into the drive shaft to your design position.

Position the hub core over the bushing taper; insert bushing screws through the bushing flange into the threaded hole in the hub coupling; torque bushing screws according to the following table:

Bushing Type |

| Screw Torque | |

|

|

| |

N·m |

| ft·lb | |

|

| ||

|

|

|

|

Q1 and Q2 | 40 |

| 29 |

|

|

|

|

R1 and R2 | 40 |

| 29 |

|

|

|

|

7