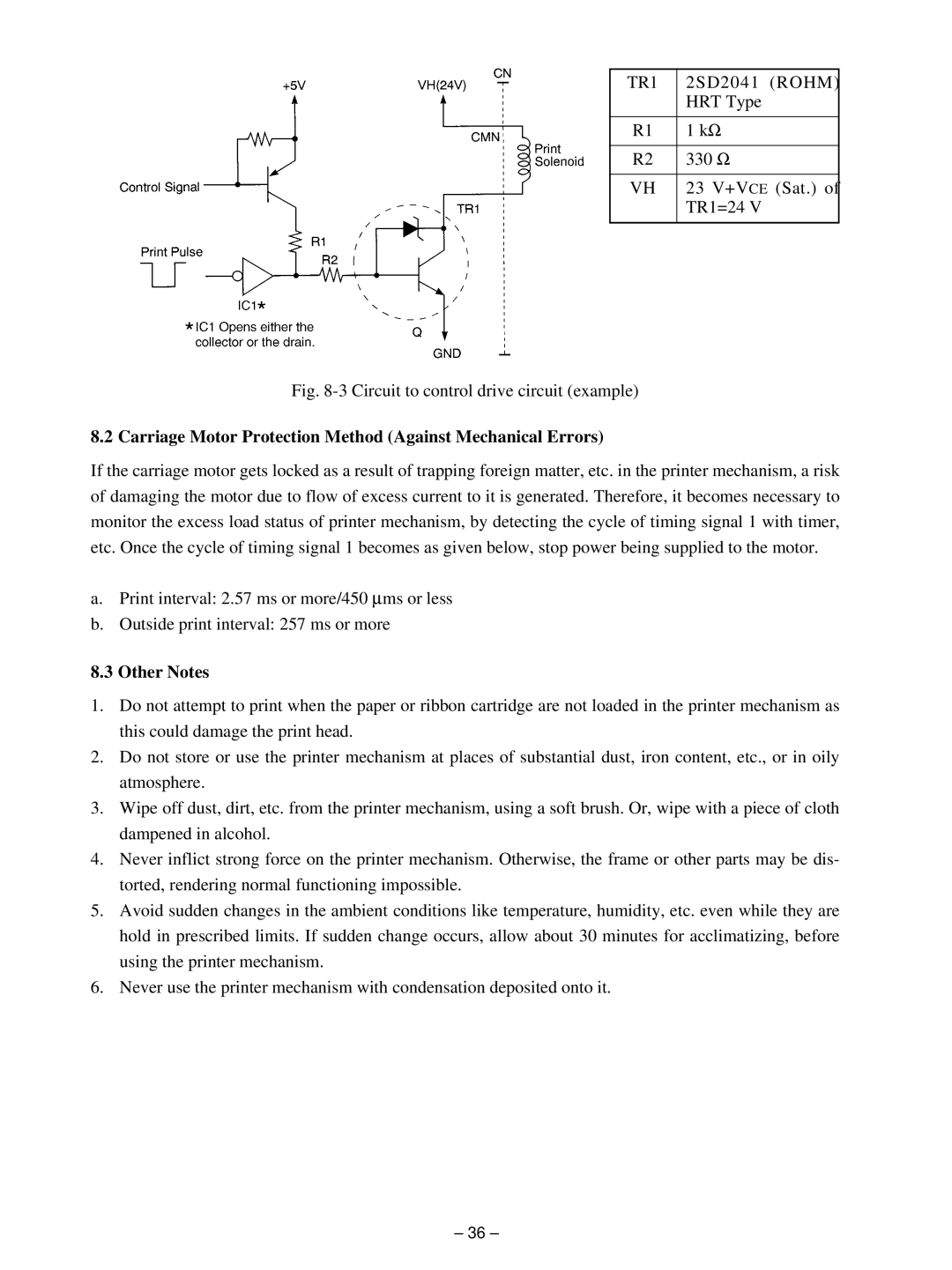

TR1 | 2SD2041 (ROHM) |

| HRT Type |

|

|

R1 | 1 kΩ |

|

|

R2 | 330 Ω |

|

|

VH | 23 V+VCE (Sat.) of |

| TR1=24 V |

|

|

Fig. 8-3 Circuit to control drive circuit (example)

8.2 Carriage Motor Protection Method (Against Mechanical Errors)

If the carriage motor gets locked as a result of trapping foreign matter, etc. in the printer mechanism, a risk of damaging the motor due to flow of excess current to it is generated. Therefore, it becomes necessary to monitor the excess load status of printer mechanism, by detecting the cycle of timing signal 1 with timer, etc. Once the cycle of timing signal 1 becomes as given below, stop power being supplied to the motor.

a.Print interval: 2.57 ms or more/450 ∝ ms or less

b.Outside print interval: 257 ms or more

8.3 Other Notes

1.Do not attempt to print when the paper or ribbon cartridge are not loaded in the printer mechanism as this could damage the print head.

2.Do not store or use the printer mechanism at places of substantial dust, iron content, etc., or in oily atmosphere.

3.Wipe off dust, dirt, etc. from the printer mechanism, using a soft brush. Or, wipe with a piece of cloth dampened in alcohol.

4.Never inflict strong force on the printer mechanism. Otherwise, the frame or other parts may be dis- torted, rendering normal functioning impossible.

5.Avoid sudden changes in the ambient conditions like temperature, humidity, etc. even while they are hold in prescribed limits. If sudden change occurs, allow about 30 minutes for acclimatizing, before using the printer mechanism.

6.Never use the printer mechanism with condensation deposited onto it.

– 36 –