186589-001 specifications

State Industries 186589-001 is a highly efficient water heater designed to meet both residential and commercial hot water demands. Known for its durability and exceptional performance, this unit is a popular choice among homeowners and business owners alike.One of the standout features of the State Industries 186589-001 is its robust construction. The tank is made from high-quality materials that offer superior insulation, reducing heat loss and improving overall energy efficiency. This ensures a longer lifespan for the unit while minimizing operating costs. The model also features a glass-lined tank, which prevents corrosion and extends the longevity of the water heater.

The 186589-001 employs innovative heating technologies, including an advanced control system that provides precise temperature regulation. This allows users to set their desired water temperature easily, ensuring optimal comfort and safety. With a powerful heating element, the water heater can quickly heat water to desired levels, providing a reliable supply for various applications, from daily bathing to commercial needs.

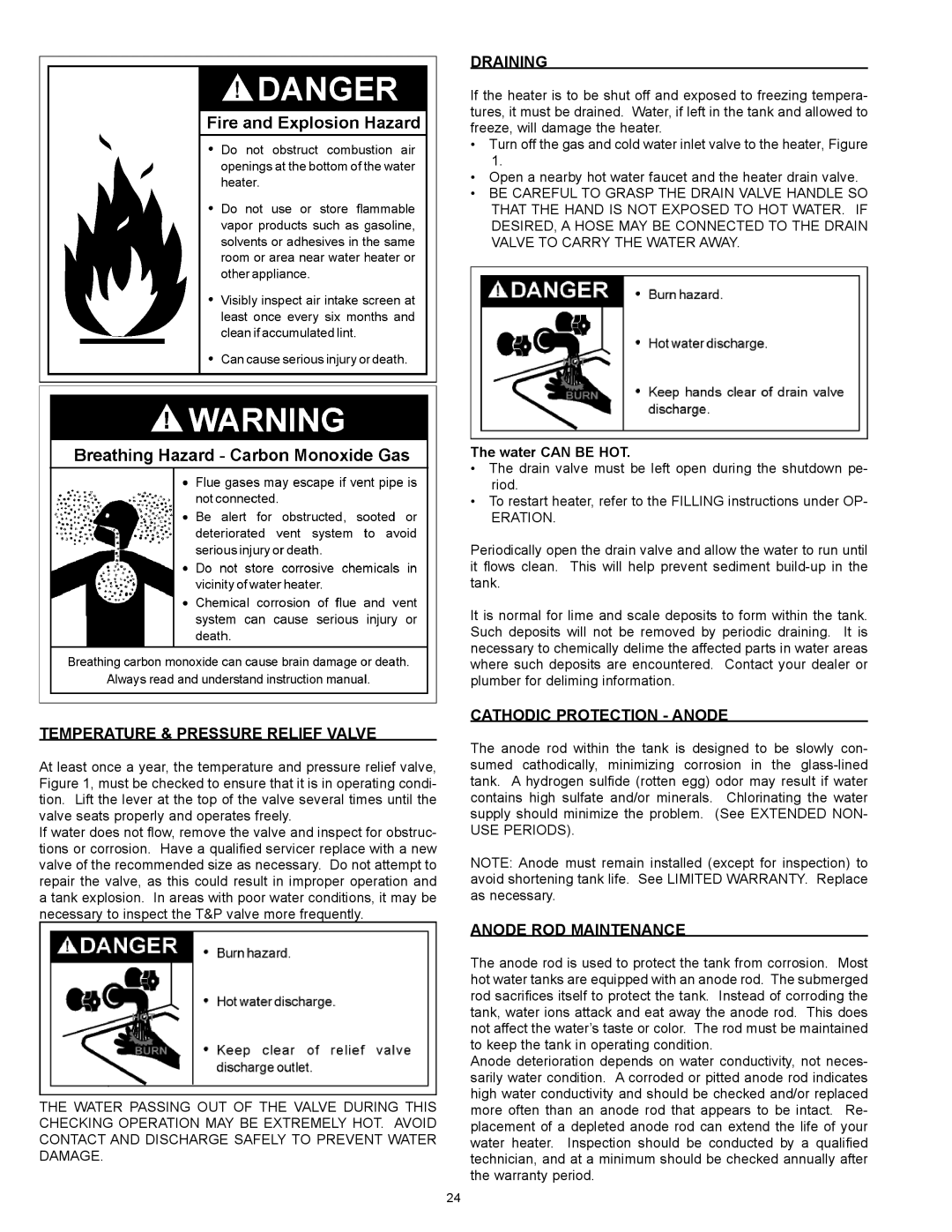

Furthermore, the State Industries water heater is equipped with multiple safety features. An automatic shut-off function is integrated to protect against overheating, ensuring user safety during operation. Additionally, the model comes with a pressure relief valve, preventing potential hazards from excessive pressure build-up.

In terms of energy efficiency, the 186589-001 meets and often exceeds current industry standards. Its design minimizes energy consumption, which not only lowers utility bills for users but also aligns with environmentally sustainable practices.

The unit is designed for easy installation, making it convenient for both professionals and DIY enthusiasts. Clear instructions are provided, and the compact size allows it to fit in tight spaces, an advantage for those with limited installation options.

Overall, the State Industries 186589-001 stands as a reliable choice for those seeking a quality water heater with excellent features, advanced technology, and safety characteristics. Its commitment to durability and efficiency makes it a valuable investment for anyone in need of consistent hot water supply.