STT 1600 specifications

The Sterling STT 1600 is a robust and versatile machine known for its efficiency and performance in various applications, particularly in the field of material handling and transportation. Designed with cutting-edge technology and a focus on user ergonomics, the STT 1600 stands out in its category for its impressive features and specifications.One of the key characteristics of the STT 1600 is its powerful engine, which provides tremendous torque and horsepower, allowing it to handle heavy loads with ease. This model is equipped with a fuel-efficient diesel engine that meets the latest emissions standards, ensuring both performance and environmental compliance. The engine’s advanced fuel management system optimizes consumption, making it an economical choice for businesses that rely on durability and cost-effectiveness.

The STT 1600 features a heavy-duty chassis that enhances stability and strength during operation. This construction ensures that the machine can withstand rigorous use in tough environments, whether for construction, warehousing, or logistics. Additionally, the equipment boasts a maximum lifting capacity that accommodates a wide variety of materials, ranging from pallets to larger equipment, making it highly versatile for different industries.

Technologically, the Sterling STT 1600 is equipped with state-of-the-art hydraulics that provide smooth and precise movement of the lifting mechanism. This includes a hydraulic lift that allows for optimal height adjustments with minimal effort from the operator. The system is designed for quick response times, which is crucial for enhancing operational efficiency in fast-paced environments.

The ergonomic design of the cab focuses on the operator's comfort and usability. It features adjustable seating, intuitive controls, and enhanced visibility, reducing fatigue and improving safety during extended shifts. Furthermore, the machine includes an advanced safety system with sensors and emergency stop mechanisms to protect both operators and on-site personnel.

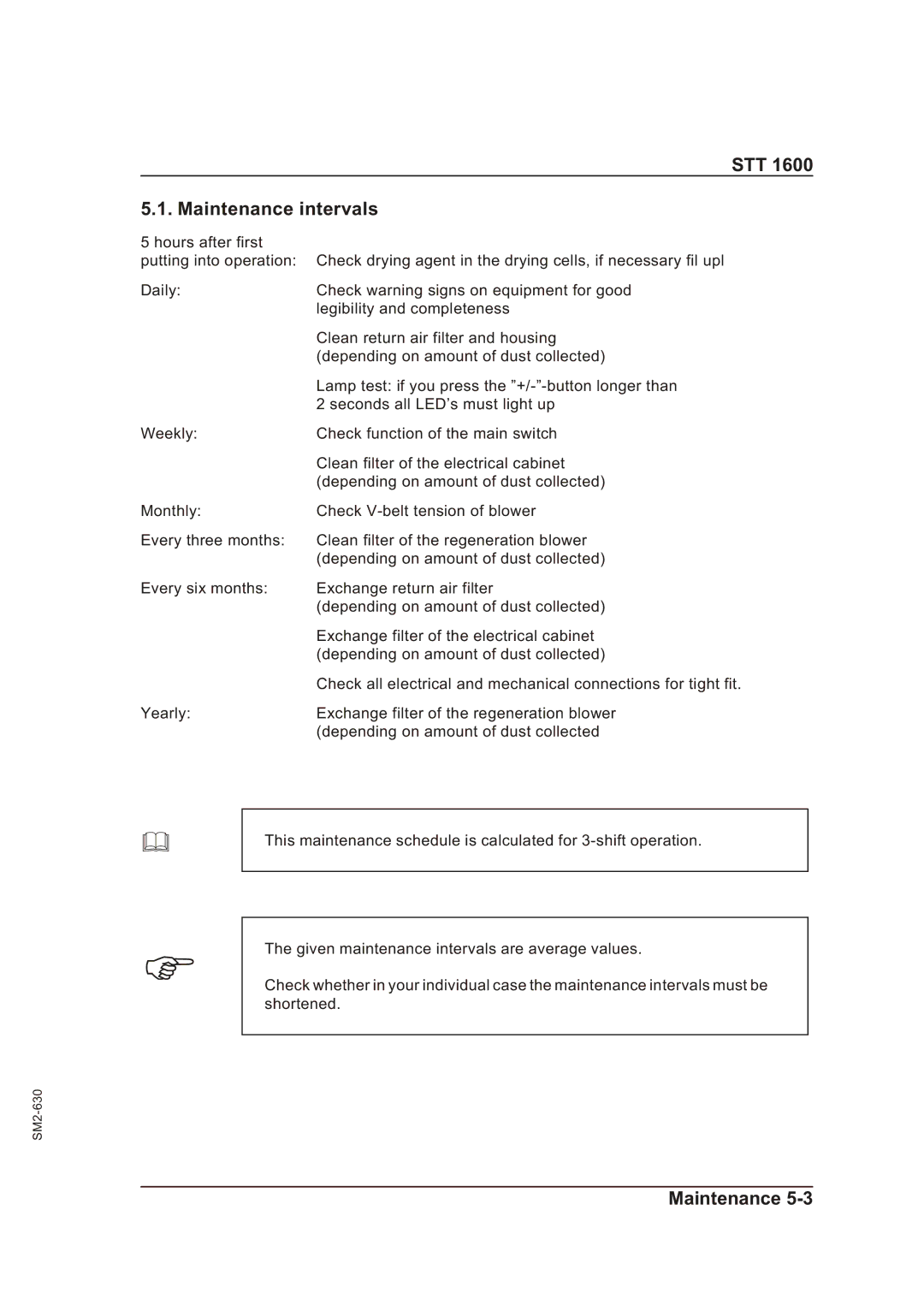

Maintenance is simplified with the STT 1600, as easy access points allow for quick inspections and repairs, minimizing downtime. The overall build quality and design reflect a commitment to longevity, making the Sterling STT 1600 a trusted choice for businesses looking to invest in reliable and high-performing machinery. In summary, the Sterling STT 1600 represents a perfect blend of power, efficiency, and technological advancements, making it an ideal solution for material handling challenges.