O111 specifications

The Stoelting O111 is an advanced soft serve ice cream machine, designed for both high-volume production and unparalleled quality. This machine showcases a blend of efficiency, reliability, and user-friendly features, making it an ideal choice for ice cream parlors, restaurants, and catering services.One of the main features of the Stoelting O111 is its high-capacity output, capable of producing a significant volume of soft serve in a short period. The machine is designed to handle busy environments, ensuring that customers receive their desserts quickly, which is essential during peak hours. It typically offers dual-flavor capabilities, allowing the simultaneous dispensing of two different ice cream flavors. This not only enhances customer choice but also provides the opportunity for creative mix-ins and swirls.

In terms of technology, the Stoelting O111 is equipped with a state-of-the-art refrigeration system that maintains optimal product consistency. This system includes a direct drive compressor, which ensures efficient cooling while minimizing energy consumption. The machine also features a temperature control panel that allows operators to adjust the serving temperature for different products, thereby enhancing the overall quality and texture of the soft serve.

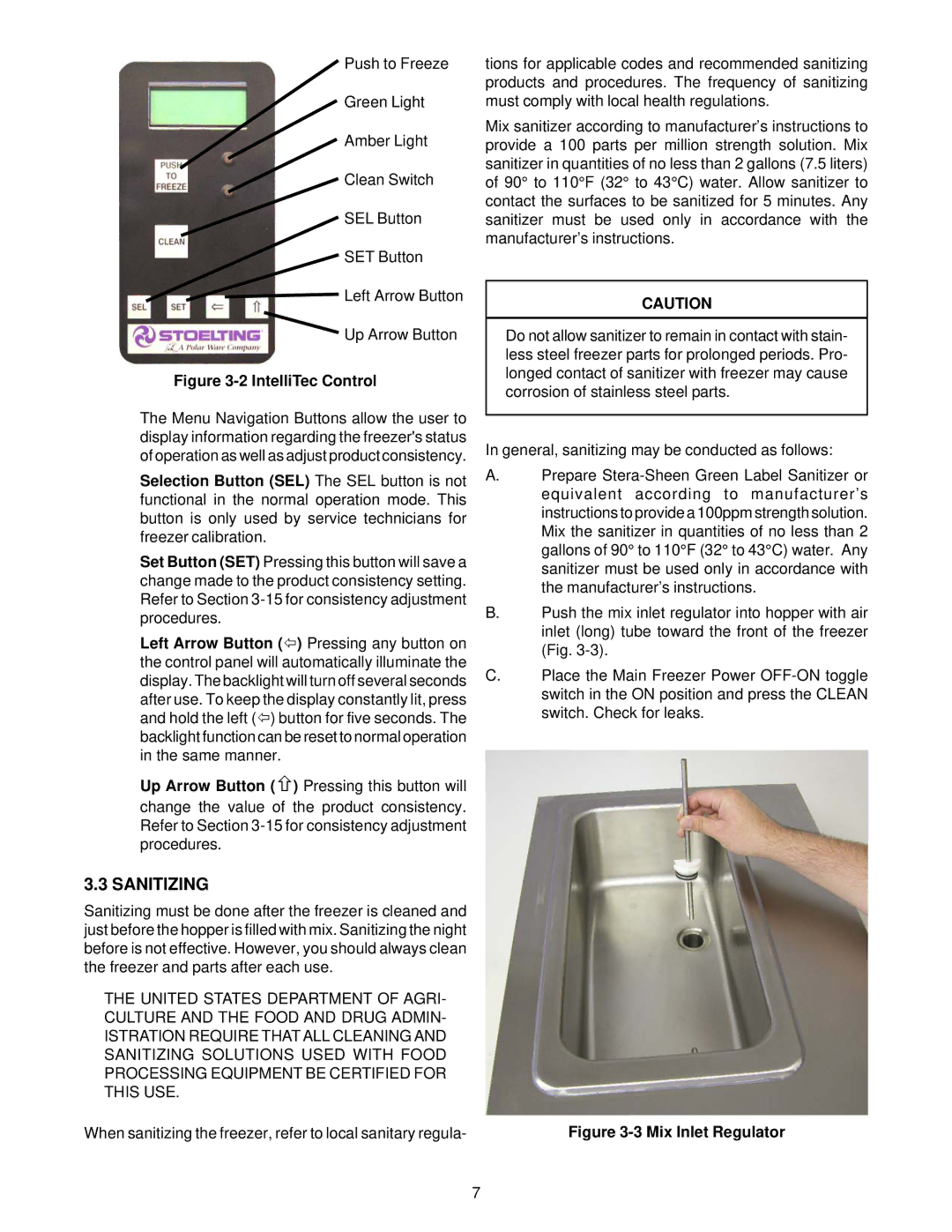

Another standout characteristic of the Stoelting O111 is its intuitive digital controls. These controls provide operators with real-time monitoring of the machine’s performance, enabling them to make quick adjustments as necessary. The easy-to-read display shows information on the mix levels, temperature settings, and machine status, allowing for proactive maintenance and minimal downtime.

Moreover, the Stoelting O111 prioritizes hygiene and ease of cleaning. It features a removable mix hopper and dispensing nozzle, facilitating thorough cleaning procedures. This focus on maintenance aligns with health standards, ensuring that the soft serve produced remains safe and high-quality.

With its robust construction, user-friendly interface, and advanced technologies, the Stoelting O111 stands out as a reliable machine that caters to the demands of the modern food service industry. Whether it's for a busy ice cream shop or a special event, the Stoelting O111 delivers exceptional performance and superior soft serve, making it a valuable addition to any establishment.