Ice Storage Provides Reduced Electrical Demand

Ice storage is the hottest thing in cooling today. It has been accepted by building owners and tenants who are concerned about utility costs.

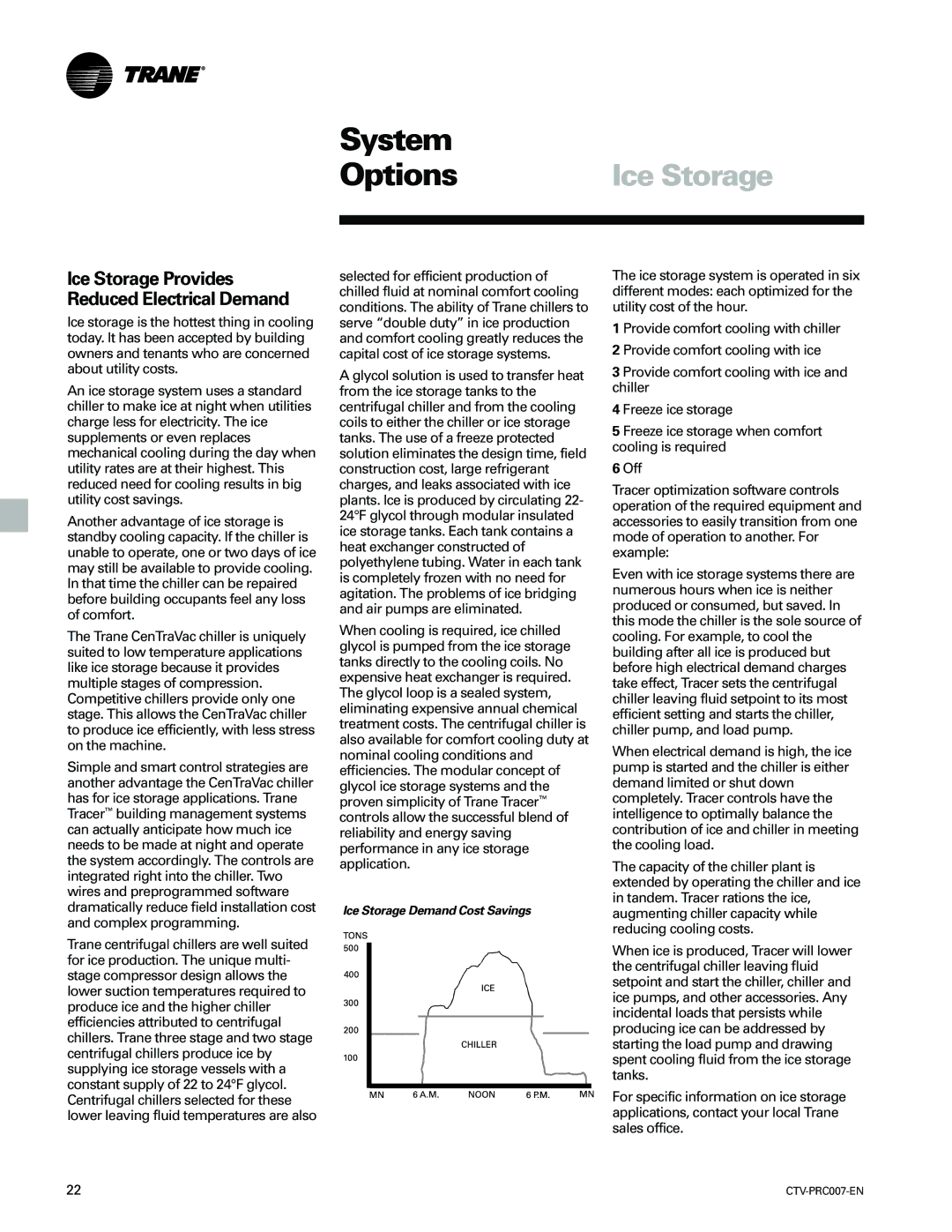

An ice storage system uses a standard chiller to make ice at night when utilities charge less for electricity. The ice supplements or even replaces mechanical cooling during the day when utility rates are at their highest. This reduced need for cooling results in big utility cost savings.

Another advantage of ice storage is standby cooling capacity. If the chiller is unable to operate, one or two days of ice may still be available to provide cooling. In that time the chiller can be repaired before building occupants feel any loss of comfort.

The Trane CenTraVac chiller is uniquely suited to low temperature applications like ice storage because it provides multiple stages of compression. Competitive chillers provide only one stage. This allows the CenTraVac chiller to produce ice efficiently, with less stress on the machine.

Simple and smart control strategies are another advantage the CenTraVac chiller has for ice storage applications. Trane Tracer™ building management systems can actually anticipate how much ice needs to be made at night and operate the system accordingly. The controls are integrated right into the chiller. Two wires and preprogrammed software dramatically reduce field installation cost and complex programming.

Trane centrifugal chillers are well suited for ice production. The unique multi- stage compressor design allows the lower suction temperatures required to produce ice and the higher chiller efficiencies attributed to centrifugal chillers. Trane three stage and two stage centrifugal chillers produce ice by supplying ice storage vessels with a constant supply of 22 to 24°F glycol. Centrifugal chillers selected for these lower leaving fluid temperatures are also

selected for efficient production of chilled fluid at nominal comfort cooling conditions. The ability of Trane chillers to serve “double duty” in ice production and comfort cooling greatly reduces the capital cost of ice storage systems.

A glycol solution is used to transfer heat from the ice storage tanks to the centrifugal chiller and from the cooling coils to either the chiller or ice storage tanks. The use of a freeze protected solution eliminates the design time, field construction cost, large refrigerant charges, and leaks associated with ice plants. Ice is produced by circulating 22- 24°F glycol through modular insulated ice storage tanks. Each tank contains a heat exchanger constructed of polyethylene tubing. Water in each tank is completely frozen with no need for agitation. The problems of ice bridging and air pumps are eliminated.

When cooling is required, ice chilled glycol is pumped from the ice storage tanks directly to the cooling coils. No expensive heat exchanger is required. The glycol loop is a sealed system, eliminating expensive annual chemical treatment costs. The centrifugal chiller is also available for comfort cooling duty at nominal cooling conditions and efficiencies. The modular concept of glycol ice storage systems and the proven simplicity of Trane Tracer™ controls allow the successful blend of reliability and energy saving performance in any ice storage application.

Ice Storage Demand Cost Savings

The ice storage system is operated in six different modes: each optimized for the utility cost of the hour.

1 Provide comfort cooling with chiller

2 Provide comfort cooling with ice

3 Provide comfort cooling with ice and chiller

4 Freeze ice storage

5 Freeze ice storage when comfort cooling is required

6Off

Tracer optimization software controls operation of the required equipment and accessories to easily transition from one mode of operation to another. For example:

Even with ice storage systems there are numerous hours when ice is neither produced or consumed, but saved. In this mode the chiller is the sole source of cooling. For example, to cool the building after all ice is produced but before high electrical demand charges take effect, Tracer sets the centrifugal chiller leaving fluid setpoint to its most efficient setting and starts the chiller, chiller pump, and load pump.

When electrical demand is high, the ice pump is started and the chiller is either demand limited or shut down completely. Tracer controls have the intelligence to optimally balance the contribution of ice and chiller in meeting the cooling load.

The capacity of the chiller plant is extended by operating the chiller and ice in tandem. Tracer rations the ice, augmenting chiller capacity while reducing cooling costs.

When ice is produced, Tracer will lower the centrifugal chiller leaving fluid setpoint and start the chiller, chiller and ice pumps, and other accessories. Any incidental loads that persists while producing ice can be addressed by starting the load pump and drawing spent cooling fluid from the ice storage tanks.

For specific information on ice storage applications, contact your local Trane sales office.