AC Input/Output Connection

To avoid overloading your Inverter/Charger, be sure to match the power requirements of the equipment you plan to run at any one time (add their total watts) with the output wattage capacity of your Inverter/Charger model (see Specifications). When figuring the power requirements of your equipment, do not confuse “continuous” wattage with “peak” wattage ratings. Most electric motors require extra power at

•DoubleBoost™ Feature

Tripp Lite Inverter/Chargers deliver up to twice their nameplate rated wattage for up to 10 seconds,* providing the extra power needed to cold start

Connection for Models with Cords and Receptacles

• OverPower™ Feature

Tripp Lite Inverter/Chargers deliver up to 150% of their name- plate rated wattage for up to 1 hour,* providing plenty of reserve power to reliably support tools and equipment longer.

* Actual duration depends on battery age, battery charge level and ambient temperature.

Plug the Inverter/Charger’s AC input cord into an outlet providing 120V AC, 60Hz. power. Make sure that the circuit you connect your Inverter/Charger to has adequate overload protection, such as a circuit breaker or a fuse. To make use of AC output (either utility/genera- tor

Warning! Consult a qualified electrician and follow all applicable electrical codes and requirements for hardwire connection. Disconnect both DC input and AC utility supply before attempting hardwiring. Use wire type THHN or equivalent with minimum temperature rating of 90°C.

Connection for Models with Hardwire Terminals

Output Connection Requirement: UL requires that the output terminals of all hardwired Inverter/Charger models must be connected to

GFCI receptacles (required receptacle manufacturer/model series: Hubbell GF8200HW or Leviton 8598 HGW copper wiring devices XHGF- 15W). When wiring GFCI receptacles to output terminals, follow the instructions provided with the GFCI receptacles.

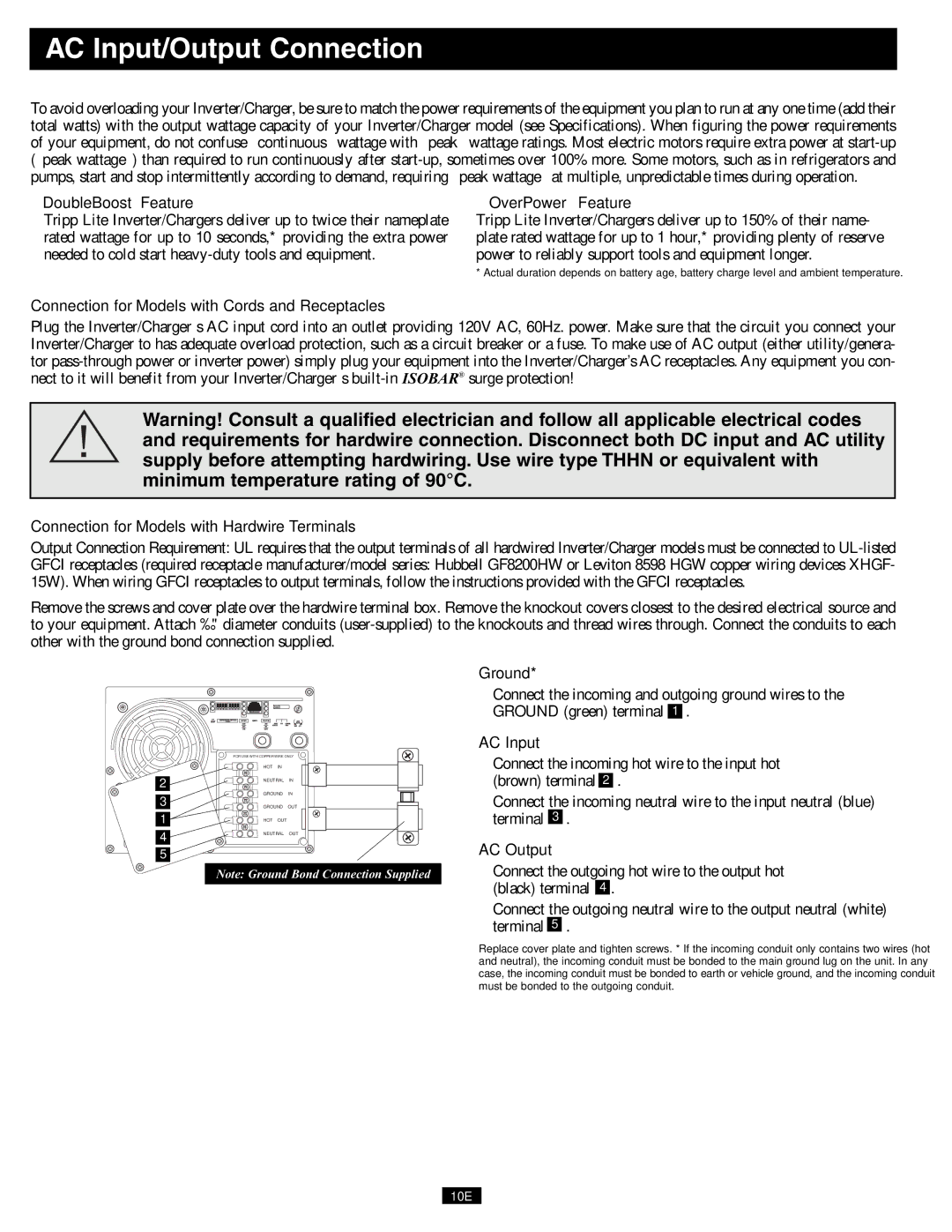

Remove the screws and cover plate over the hardwire terminal box. Remove the knockout covers closest to the desired electrical source and to your equipment. Attach ½" diameter conduits

| “FOR USE WITH COPPER WIRE ONLY” | ||

| HOT | IN |

|

2 | NEUTRAL | IN | |

|

|

| |

| GROUND | IN | |

3 | GROUND | OUT | |

1 | HOT | OUT |

|

Ground*

•Connect the incoming and outgoing ground wires to the GROUND (green) terminal 1 .

AC Input

•Connect the incoming hot wire to the input hot (brown) terminal 2 .

•Connect the incoming neutral wire to the input neutral (blue) terminal 3 .

4

5

NEUTRAL OUT

AC Output

Note: Ground Bond Connection Supplied

•Connect the outgoing hot wire to the output hot (black) terminal 4 .

•Connect the outgoing neutral wire to the output neutral (white) terminal 5 .

Replace cover plate and tighten screws. * If the incoming conduit only contains two wires (hot and neutral), the incoming conduit must be bonded to the main ground lug on the unit. In any case, the incoming conduit must be bonded to earth or vehicle ground, and the incoming conduit must be bonded to the outgoing conduit.

10E