Section 5: Maintenance |

|

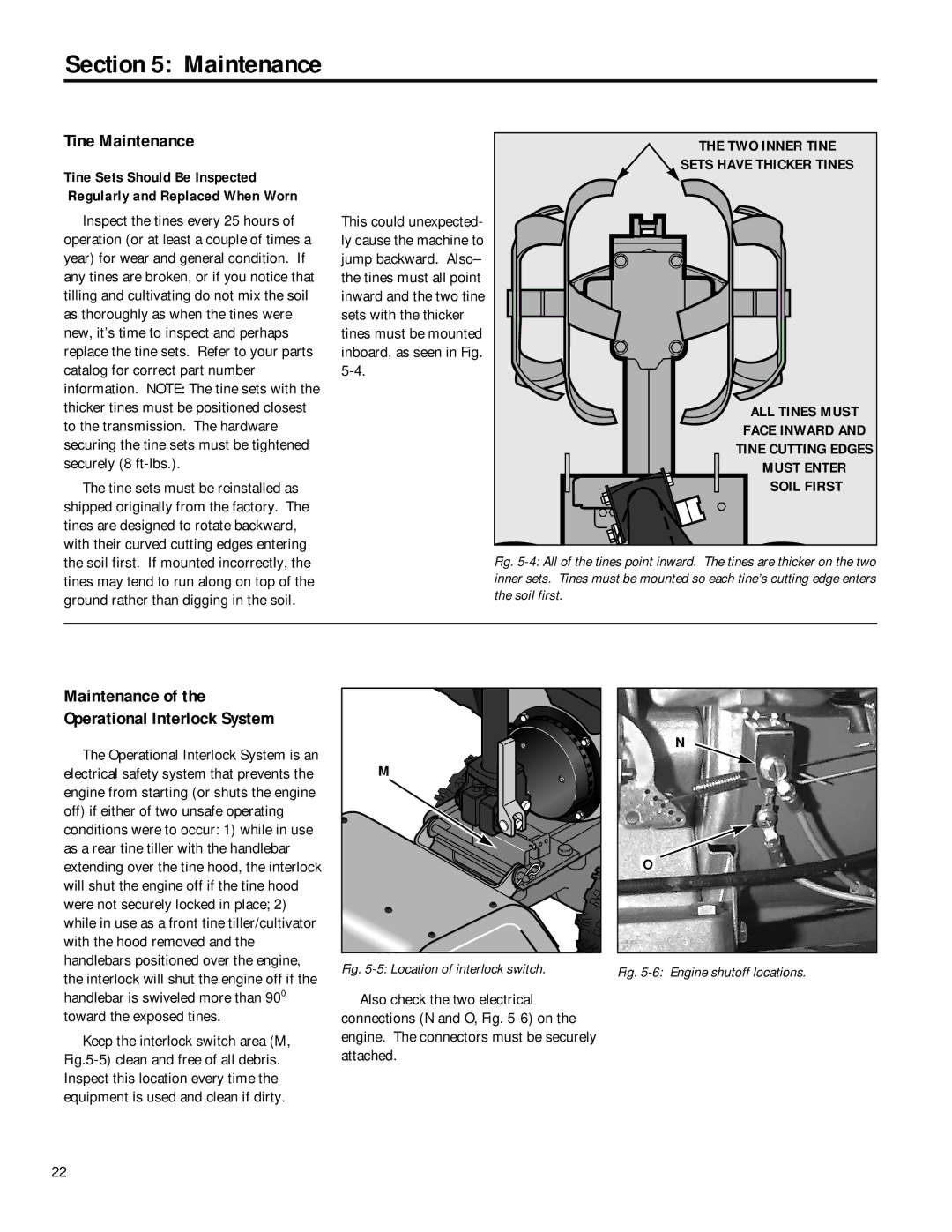

Tine Maintenance | THE TWO INNER TINE |

Tine Sets Should Be Inspected | SETS HAVE THICKER TINES |

| |

Regularly and Replaced When Worn |

|

Inspect the tines every 25 hours of | This could unexpected- |

operation (or at least a couple of times a | ly cause the machine to |

year) for wear and general condition. If | jump backward. Also– |

any tines are broken, or if you notice that | the tines must all point |

tilling and cultivating do not mix the soil | inward and the two tine |

as thoroughly as when the tines were | sets with the thicker |

new, it’s time to inspect and perhaps | tines must be mounted |

replace the tine sets. Refer to your parts | inboard, as seen in Fig. |

catalog for correct part number | |

information. NOTE: The tine sets with the |

|

thicker tines must be positioned closest | ALL TINES MUST |

to the transmission. The hardware | FACE INWARD AND |

securing the tine sets must be tightened | TINE CUTTING EDGES |

securely (8 | MUST ENTER |

The tine sets must be reinstalled as | SOIL FIRST |

shipped originally from the factory. The |

|

tines are designed to rotate backward, |

|

with their curved cutting edges entering | Fig. |

the soil first. If mounted incorrectly, the | |

tines may tend to run along on top of the | inner sets. Tines must be mounted so each tine’s cutting edge enters |

ground rather than digging in the soil. | the soil first. |

Maintenance of the |

|

| |

Operational Interlock System |

|

| |

The Operational Interlock System is an |

| N | |

M |

| ||

electrical safety system that prevents the |

| ||

engine from starting (or shuts the engine |

|

| |

off) if either of two unsafe operating |

|

| |

conditions were to occur: 1) while in use |

|

| |

as a rear tine tiller with the handlebar |

| O | |

extending over the tine hood, the interlock |

| ||

will shut the engine off if the tine hood |

|

| |

were not securely locked in place; 2) |

|

| |

while in use as a front tine tiller/cultivator |

|

| |

with the hood removed and the |

|

| |

handlebars positioned over the engine, | Fig. | Fig. | |

the interlock will shut the engine off if the | |||

|

| ||

handlebar is swiveled more than 900 | Also check the two electrical |

| |

toward the exposed tines. | connections (N and O, Fig. |

| |

Keep the interlock switch area (M, | engine. The connectors must be securely |

| |

| attached. |

| |

Inspect this location every time the |

|

| |

equipment is used and clean if dirty. |

|

|

22