Section 5: Maintenance

ENGINE MAINTENANCE

Engine Oil Maintenance

Change engine oil after the first two (2) hours of new operation. Thereafter, change the oil every fifty (50) operating hours (or sooner if the work environment is very dirty or dusty).

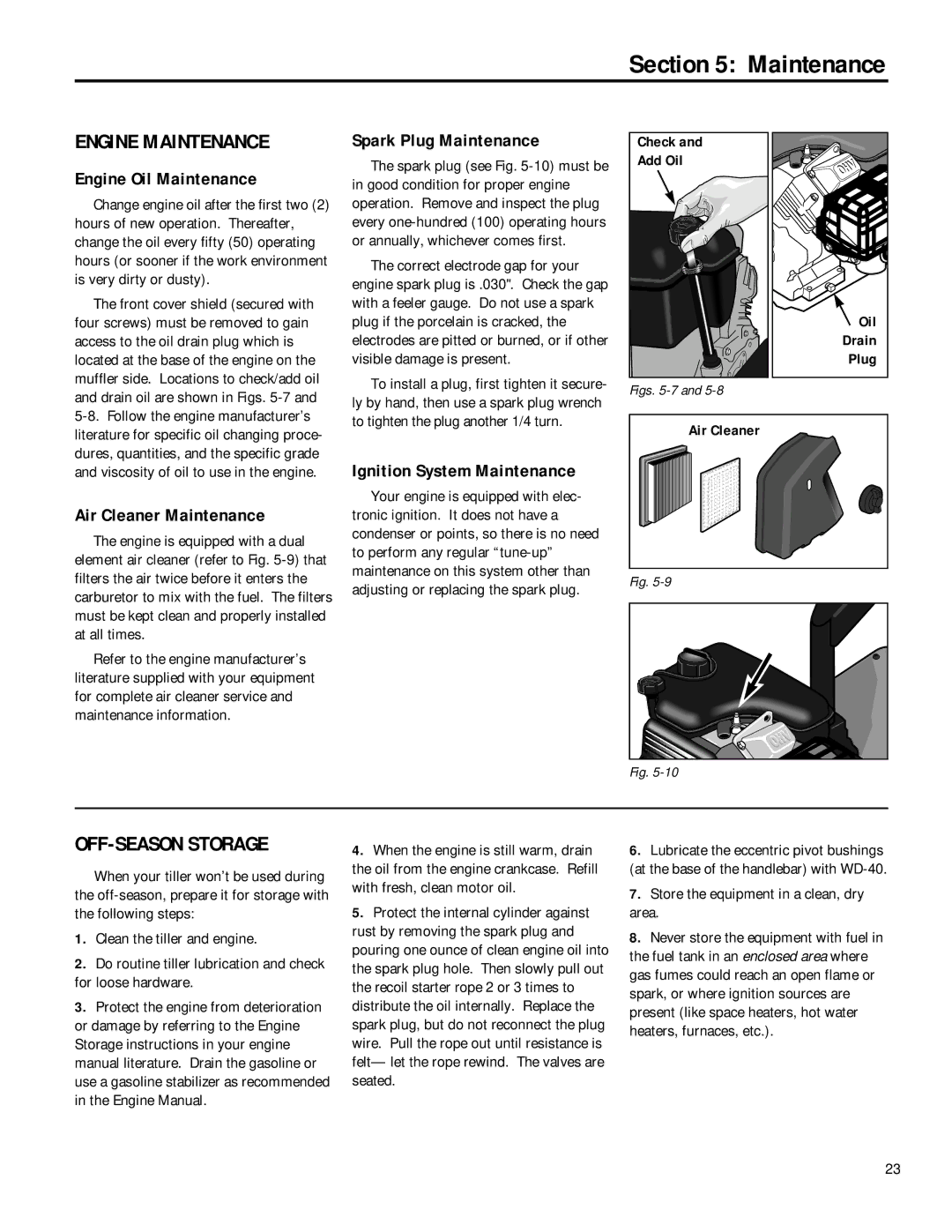

The front cover shield (secured with four screws) must be removed to gain access to the oil drain plug which is located at the base of the engine on the muffler side. Locations to check/add oil and drain oil are shown in Figs.

Air Cleaner Maintenance

The engine is equipped with a dual element air cleaner (refer to Fig.

Refer to the engine manufacturer’s literature supplied with your equipment for complete air cleaner service and maintenance information.

Spark Plug Maintenance

The spark plug (see Fig.

The correct electrode gap for your engine spark plug is .030". Check the gap with a feeler gauge. Do not use a spark plug if the porcelain is cracked, the electrodes are pitted or burned, or if other visible damage is present.

To install a plug, first tighten it secure- ly by hand, then use a spark plug wrench to tighten the plug another 1/4 turn.

Ignition System Maintenance

Your engine is equipped with elec- tronic ignition. It does not have a condenser or points, so there is no need to perform any regular

Check and |

Add Oil |

Oil |

Drain |

Plug |

Figs. |

Air Cleaner |

Fig. |

Fig. |

OFF-SEASON STORAGE

When your tiller won’t be used during the

1.Clean the tiller and engine.

2.Do routine tiller lubrication and check for loose hardware.

3.Protect the engine from deterioration or damage by referring to the Engine Storage instructions in your engine manual literature. Drain the gasoline or use a gasoline stabilizer as recommended in the Engine Manual.

4.When the engine is still warm, drain the oil from the engine crankcase. Refill with fresh, clean motor oil.

5.Protect the internal cylinder against rust by removing the spark plug and pouring one ounce of clean engine oil into the spark plug hole. Then slowly pull out the recoil starter rope 2 or 3 times to distribute the oil internally. Replace the spark plug, but do not reconnect the plug wire. Pull the rope out until resistance is felt— let the rope rewind. The valves are seated.

6.Lubricate the eccentric pivot bushings (at the base of the handlebar) with

7.Store the equipment in a clean, dry area.

8.Never store the equipment with fuel in the fuel tank in an enclosed area where gas fumes could reach an open flame or spark, or where ignition sources are present (like space heaters, hot water heaters, furnaces, etc.).

23