Section 4: Operation

•Turn the vehicle’s engine off and apply its parking brake.

•Position the loading vehicle so that the ramp angle is as flat as possible (the less incline to the ramp, the better).

Loading the Tiller

1.Use loading ramps that are strong and wide enough to safely hold the weight of the tiller and the operator combined— your tiller weighs between 280 and 325 lbs.

2.Move the Tines/PTO Clutch Lever (Figure

3.Set the Depth Regulator lever (Figure

4.Move Wheel Speed Lever (Figure

5.Shift the Wheels/Tines/PTO Lever (Figure

6.Prevent tiller from rolling in vehicle. Leave Wheel Speed Lever in FAST or SLOW position, chock wheels with blocks and tie down the tiller.

Figure 4-7: To go up ramps, use

Unloading the Tiller

IMPORTANT: Never unload the tiller in FORWARD drive. The tiller could tip forward and expose you to the tines (which should be disengaged as instructed).

1.Use loading ramps that are strong and wide enough to safely hold the weight of the tiller and the operator combined— your tiller weighs between 280 and 325 lbs.

2.Move the Tines/PTO Clutch Lever (Figure

3.Set the Depth Regulator Lever (Figure

4.Move Wheel Speed Lever (Figure

IMPORTANT: Look behind you before you back down the ramp to ensure that all is clear. While descending, keep checking for obstacles behind you.

5.Move and hold the Wheels/Tines/PTO Lever into REVERSE drive and back down the ramps (Figure

Figure 4-8: To go down ramps, use REVERSE drive.

Changing Speed Belts

Your tiller has two

–you pick one or the other by deciding which set of pulley grooves to move the forward belt into. By moving the belt from one speed range into the other, in combination with the FAST and SLOW wheel speeds, you obtain a choice of four different forward wheel speeds and two different tine speeds.

WARNING

To help avoid serious personal injury, stop the engine, remove the ignition key, disconnect spark plug wire and move the wire away from the spark plug, and let engine and muffler cool down before changing belt speeds.

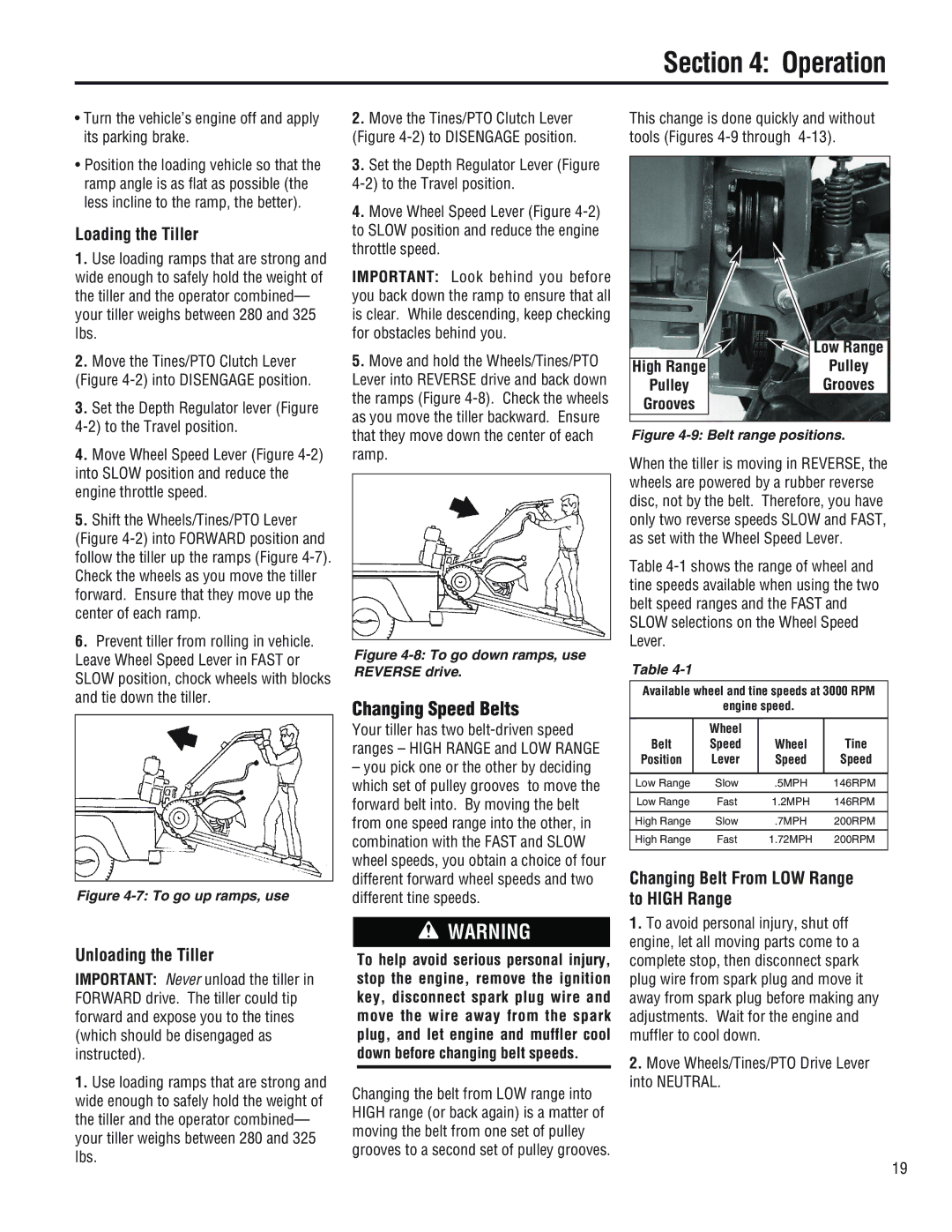

Changing the belt from LOW range into HIGH range (or back again) is a matter of moving the belt from one set of pulley grooves to a second set of pulley grooves.

This change is done quickly and without tools (Figures

| Low Range |

High Range | Pulley |

Pulley | Grooves |

Grooves |

|

Figure 4-9: Belt range positions.

When the tiller is moving in REVERSE, the wheels are powered by a rubber reverse disc, not by the belt. Therefore, you have only two reverse speeds SLOW and FAST, as set with the Wheel Speed Lever.

Table

Table

Available wheel and tine speeds at 3000 RPM

engine speed.

| Wheel |

| Tine |

Belt | Speed | Wheel | |

Position | Lever | Speed | Speed |

|

|

|

|

Low Range | Slow | .5MPH | 146RPM |

|

|

|

|

Low Range | Fast | 1.2MPH | 146RPM |

|

|

|

|

High Range | Slow | .7MPH | 200RPM |

|

|

|

|

High Range | Fast | 1.72MPH | 200RPM |

|

|

|

|

Changing Belt From LOW Range to HIGH Range

1.To avoid personal injury, shut off engine, let all moving parts come to a complete stop, then disconnect spark plug wire from spark plug and move it away from spark plug before making any adjustments. Wait for the engine and muffler to cool down.

2.Move Wheels/Tines/PTO Drive Lever into NEUTRAL.

19