Warnings, Cautions and Notes

T h roughout this guide, the following conventions a re used to identify important information.

WARNING - Warning messages indicate where personal injury could result from not following the correct procedures.

CAUTION - Caution messages indicate where damage to equipment could result from not following the correct procedures.

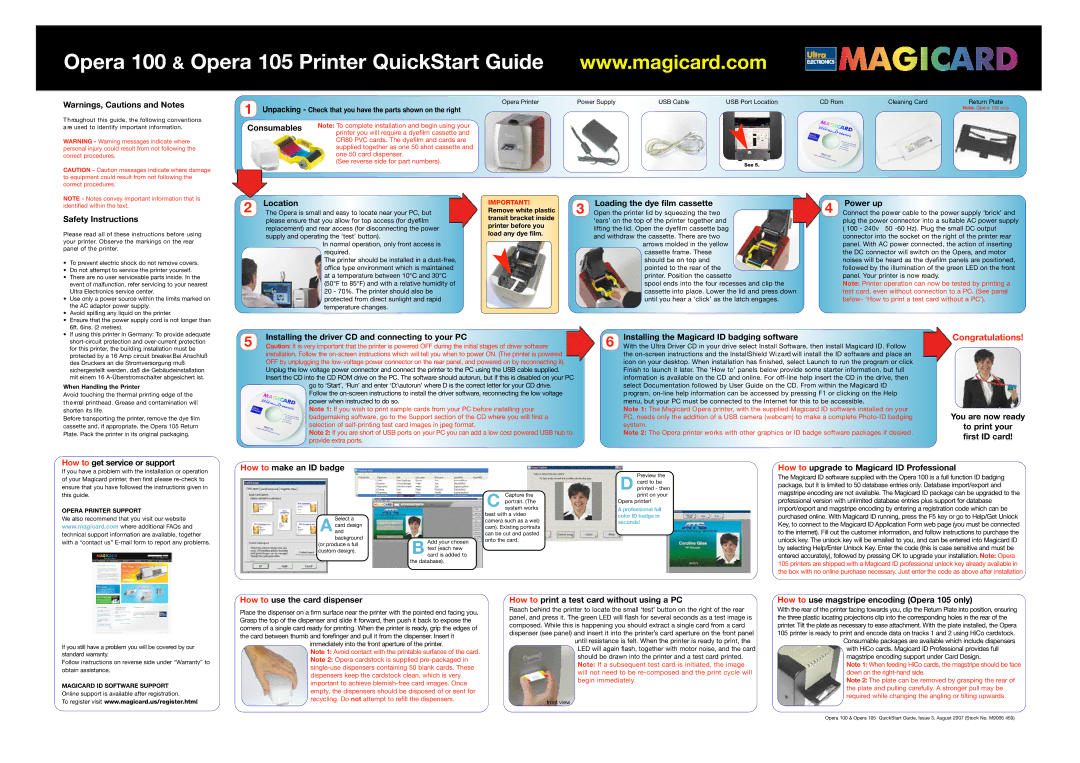

1 Unpacking - Check that you have the parts shown on the right

Consumables Note: To complete installation and begin using your printer you will require a dyefilm cassette and

CR80 PVC cards. The dyefilm and cards are supplied together as one 50 shot cassette and one 50 card dispenser.

(See reverse side for part numbers).

Opera Printer | Power Supply | USB Cable | USB Port Location | CD Rom | Cleaning Card | Return Plate |

| | | | | | Note: Opera 105 only |

See 5.

NOTE - Notes convey important information that is identified within the text.

Safety Instructions

Please read all of these instructions before using your printer. Observe the markings on the rear panel of the printer.

• To prevent electric shock do not remove covers. |

• Do not attempt to service the printer yourself. |

• There are no user serviceable parts inside. In the |

event of malfunction, refer servicing to your nearest |

Ultra Electronics service center. |

• Use only a power source within the limits marked on |

the AC adaptor power supply. |

• Avoid spilling any liquid on the printer. |

• Ensure that the power supply cord is not longer than |

6ft. 6ins. (2 metres). |

Location

2 The Opera is small and easy to locate near your PC, but please ensure that you allow for top access (for dyefilm replacement) and rear access (for disconnecting the power supply and operating the ‘test’ button).

In normal operation, only front access is required.

The printer should be installed in a dust-free, office type environment which is maintained at a temperature between 10°C and 30°C (50°F to 85°F) and with a relative humidity of 20 - 70%. The printer should also be protected from direct sunlight and rapid temperature changes.

IMPORTANT! | 3 | Loading the dye film cassette | 4 | Power up |

Remove white plastic | Open the printer lid by squeezing the two | Connect the power cable to the power supply ‘brick’ and |

transit bracket inside | | ‘ears’ on the top of the printer together and | | plug the power connector into a suitable AC power supply |

printer before you | | |

| lifting the lid. Open the dyefilm cassette bag | | ( 100 - 240v 50 -60 Hz). Plug the small DC output |

load any dye film. | | |

| and withdraw the cassette. There are two | | connector into the socket on the right of the printer rear |

| | |

| | arrows molded in the yellow | | panel. With AC power connected, the action of inserting |

| | cassette frame. These | | the DC connector will switch on the Opera, and motor |

| | should be on top and | | noises will be heard as the dyefilm panels are positioned, |

| | pointed to the rear of the | | followed by the illumination of the green LED on the front |

| | printer. Position the cassette | | panel. Your printer is now ready. |

| | spool ends into the four recesses and clip the | | Note: Printer operation can now be tested by printing a |

| | cassette into place. Lower the lid and press down | | test card, even without connection to a PC. (See panel |

| | until you hear a ‘click’ as the latch engages. | | below- ‘How to print a test card without a PC’). |

• If using this printer in Germany: To provide adequate |

short-circuit protection and over-current protection |

for this printer, the building installation must be |

protected by a 16 Amp circuit breaker.Bei Anschluß |

des Druckers an die Stromversorgung muß |

sichergestellt werden, daß die Gebäudeinstallation |

mit einem 16 A-Überstromschalter abgesichert ist. |

When Handling the Printer

Avoid touching the thermal printing edge of the

th ermal printhead. Grease and contamination will shorten its life.

Before transporting the printer, remove the dye film cassette and, if appropriate, the Opera 105 Return Plate. Pack the printer in its original packaging.

5 | Installing the driver CD and connecting to your PC |

Caution: It is very important that the printer is powered OFF during the initial stages of driver software |

installation. Follow the on-screen instructions which will tell you when to power ON. (The printer is powered OFF by unplugging the low-voltage power connector on the rear panel, and powered on by reconnecting it). Unplug the low voltage power connector and connect the printer to the PC using the USB cable supplied.

Insert the CD into the CD ROM drive on the PC. The software should autorun, but if this is disabled on your PC go to ‘Start’, ‘Run’ and enter ‘D:\autorun’ where D is the correct letter for your CD drive.

Follow the on-screen instructions to install the driver software, reconnecting the low voltage power when instructed to do so.

Note 1: If you wish to print sample cards from your PC before installing your badgemaking software, go to the Support section of the CD where you will find a selection of self-printing test card images in jpeg format.

Note 2: If you are short of USB ports on your PC you can add a low cost powered USB hub to provide extra ports .

Installing the Magicard ID badging software

6 With the Ultra Driver CD in your drive select Install Software, then install Magicard ID. Follow the on-screen instructions and the InstallShield Wizard will install the ID software and place an icon on your desktop. When installation has finished, select Launch to run the program or click Finish to launch it later. The ‘How to’ panels below provide some starter information, but full information is available on the CD and online. For off-line help insert the CD in the drive, then select Documentation followed by User Guide on the CD. From within the Magicard ID

p rogram, on-line help information can be accessed by pressing F1 or clicking on the Help menu, but your PC must be connected to the Internet for this to be accessible.

Note 1: The Magicard Opera printer, with the supplied Magicard ID software installed on your PC, needs only the addition of a USB camera (webcam) to make a complete Photo-ID badging system.

Note 2: The Opera printer works with other graphics or ID badge software packages if desired.

Congratulations!

You are now ready

to print your first ID card!

How to get service or support

If you have a problem with the installation or operation of your Magicard printer, then first please re-check to ensure that you have followed the instructions given in this guide.

OPERA PRINTER SUPPORT

We also recommend that you visit our website www.magicard.com where additional FAQs and technical support information are available, together with a “contact us” E-mail form to report any problems.

How to make an ID badge

| Select a | |

| A andcard design | |

| background | Add your chosen |

| (or produce a full |

| text (each new |

| custom design). |

| B card is added to |

| |

| | the database). |

Capture the C portrait. (The system works

best with a video camera such as a web cam). Existing portraits can be cut and pasted onto the card.

Preview the

D card to be printed - then print on your

Opera printer!

A professional full color ID badge in seconds!

How to upgrade to Magicard ID Professional

The Magicard ID software supplied with the Opera 100 is a full function ID badging package, but it is limited to 50 database entries only. Database import/export and magstripe encoding are not available. The Magicard ID package can be upgraded to the professional version with unlimited database entries plus support for database import/export and magstripe encoding by entering a registration code which can be purchased online. With Magicard ID running, press the F5 key or go to Help/Get Unlock Key, to connect to the Magicard ID Application Form web page (you must be connected to the internet). Fill out the customer information, and follow instructions to purchase the unlock key. The unlock key will be emailed to you, and can be entered into Magicard ID by selecting Help/Enter Unlock Key. Enter the code (this is case sensitive and must be entered accurately), followed by pressing OK to upgrade your installation. Note: Opera 105 printers are shipped with a Magicard ID professional unlock key already available in the box with no online purchase necessary. Just enter the code as above after installation

If you still have a problem you will be covered by our standard warranty.

Follow instructions on reverse side under “Warranty” to obtain assistance.

MAGICARD ID SOFTWARE SUPPORT

Online support is available after registration.

To register visit www.magicard.us/register.html

How to use the card dispenser

Place the dispenser on a firm surface near the printer with the pointed end facing you. Grasp the top of the dispenser and slide it forward, then push it back to expose the corners of a single card ready for printing. When the printer is ready, grip the edges of the card between thumb and forefinger and pull it from the dispenser. Insert it

immediately into the front aperture of the printer.

Note 1: Avoid contact with the printable surfaces of the card .

Note 2: Opera cardstock is supplied pre-packaged in single-use dispensers containing 50 blank cards. These dispensers keep the cardstock clean, which is very important to achieve blemish-free card images. Once empty, the dispensers should be disposed of or sent for recycling. Do not attempt to refill the dispensers.

How to print a test card without using a PC

Reach behind the printer to locate the small ‘test’ button on the right of the rear panel, and press it. The green LED will flash for several seconds as a test image is composed. While this is happening you should extract a single card from a card dispenser (see panel) and insert it into the printer’s card aperture on the front panel

until resistance is felt. When the printer is ready to print, the LED will again flash, together with motor noise, and the card should be drawn into the printer and a test card printed. Note: If a subsequent test card is initiated, the image will not need to be re-composed and the print cycle will begin immediately.

front view

How to use magstripe encoding (Opera 105 only)

With the rear of the printer facing towards you, clip the Return Plate into position, ensuring the three plastic locating projections clip into the corresponding holes in the rear of the printer. Tilt the plate as necessary to ease attachment. With the plate installed, the Opera 105 printer is ready to print and encode data on tracks 1 and 2 using HiCo cardstock .

Consumable packages are available which include dispensers with HiCo cards. Magicard ID Professional provides full magstripe encoding support under Card Design.

Note 1: When feeding HiCo cards, the magstripe should be face down on the right-hand side.

Note 2: The plate can be removed by grasping the rear of the plate and pulling carefully. A stronger pull may be required while changing the angling or tilting upwards.