A

NOTE: Do not vent your Dutchwest stove into a factory- built

Floor Protection

A tremendous amount of heat radiates from the bottom plate of your Dutchwest stove. The floor area directly under and around the stove will require protection from radiant heat as well as from stray sparks or embers that may escape the firebox.

Heat protection is provided by the CFM Corporation Bottom Heat Shield. Spark, ember and thermal protec- tion must be provided by a floor protector constructed with noncombustible material as specified.

In the US and Canada most installations will require that the bottom heat shield must be attached. Only when the stove is placed on a completely noncombusti- ble surface such as unpainted concrete over earth may it be used without the heat shield.

Even when the bottom heat shield is installed, you must provide special protection to the floor beneath. For installation with the heat shield attached, use an approved 1” (25mm) noncombustible hearth pad with K

=0.84 BTU/in ft2 hr °F or an equivalent material with an

Protection requirements vary somewhat between the United States and Canada as follows:

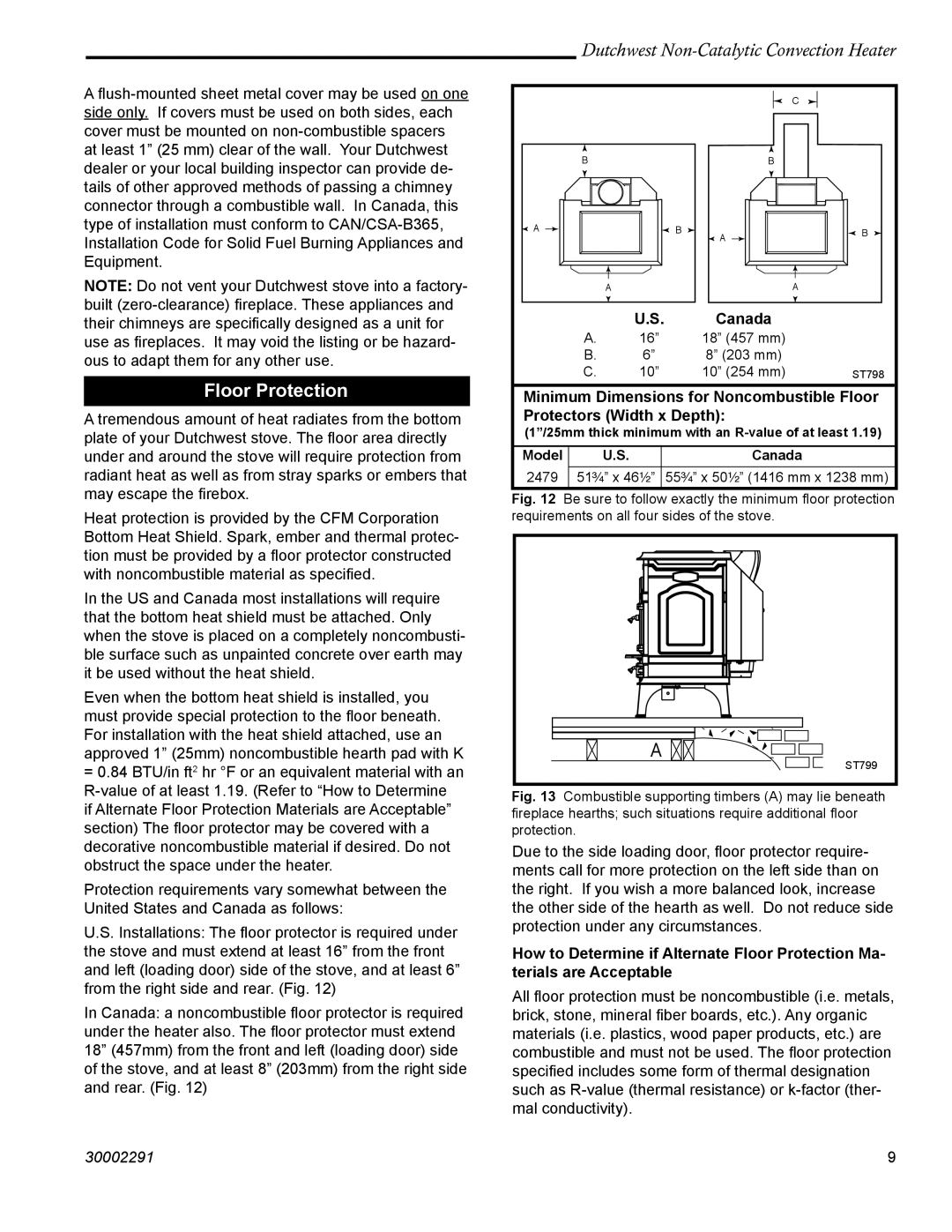

U.S. Installations: The floor protector is required under the stove and must extend at least 16” from the front and left (loading door) side of the stove, and at least 6” from the right side and rear. (Fig. 12)

In Canada: a noncombustible floor protector is required under the heater also. The floor protector must extend 18” (457mm) from the front and left (loading door) side of the stove, and at least 8” (203mm) from the right side and rear. (Fig. 12)

Dutchwest

C

BB

![]() A

A ![]()

![]() B

B ![]()

![]() A

A ![]()

![]() B

B

AA

U.S. Canada

A.16” 18” (457 mm)

B.6” 8” (203 mm)

C. | 10” | 10” (254 mm) | ST798 |

Minimum Dimensions for Noncombustible Floor Protectors (Width x Depth):

(1”/25mm thick minimum with an

Model | U.S. | Canada |

|

|

|

2479 | 51³⁄₄” x 46¹⁄₂” | 55³⁄₄” x 50¹⁄₂” (1416 mm x 1238 mm) |

|

|

|

Fig. 12 Be sure to follow exactly the minimum floor protection requirements on all four sides of the stove.

A ![]()

![]()

![]()

![]()

![]()

ST799

Fig. 13 Combustible supporting timbers (A) may lie beneath fireplace hearths; such situations require additional floor protection.

Due to the side loading door, floor protector require- ments call for more protection on the left side than on the right. If you wish a more balanced look, increase the other side of the hearth as well. Do not reduce side protection under any circumstances.

How to Determine if Alternate Floor Protection Ma- terials are Acceptable

All floor protection must be noncombustible (i.e. metals, brick, stone, mineral fiber boards, etc.). Any organic materials (i.e. plastics, wood paper products, etc.) are combustible and must not be used. The floor protection specified includes some form of thermal designation such as

30002291 | 9 |