Encore 1450

D

B

![]() E

E ![]()

![]()

![]() E

E ![]()

F

A

C

E ![]()

![]()

![]() E

E ![]()

F

A

EXAMPLE: The specified floor protector should be 1/2- inch thick material with

Step a: Use formula above to convert specification to

Step b: Calculate R of proposed system. 4” brick of r = 0.2, therefore:

Rbrick = 0.2 x 4 = 0.8

1/8” mineral board of k = 0.29, therefore

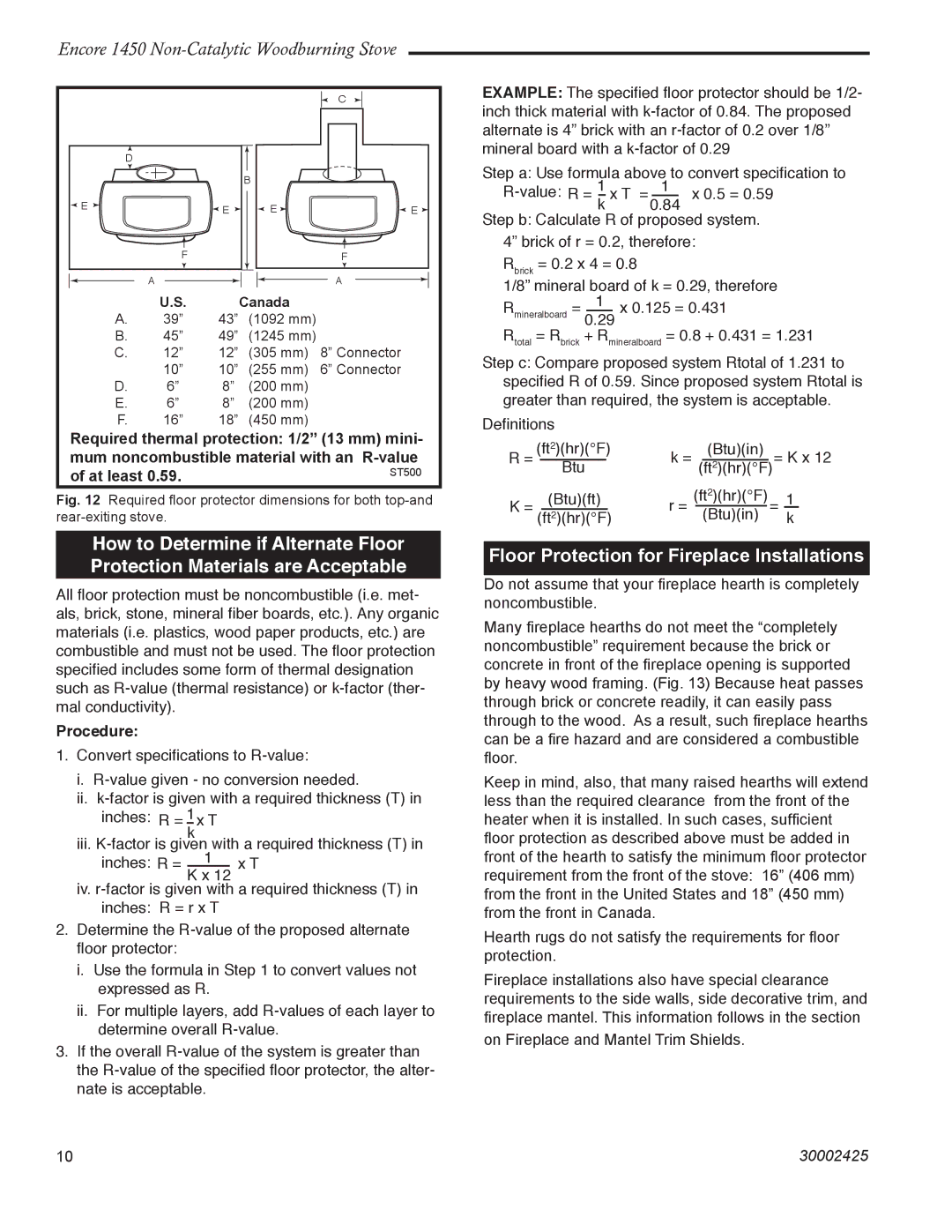

U.S. Canada

A.39” 43” (1092 mm)

B.45” 49” (1245 mm)

C.12” 12” (305 mm) 8” Connector

10” 10” (255 mm) 6” Connector

D.6” 8” (200 mm)

E.6” 8” (200 mm)

F.16” 18” (450 mm)

Required thermal protection: 1/2” (13 mm) mini- mum noncombustible material with an

of at least 0.59. | ST500 |

Fig. 12 Required floor protector dimensions for both top-and rear-exiting stove.

How to Determine if Alternate Floor Protection Materials are Acceptable

All floor protection must be noncombustible (i.e. met- als, brick, stone, mineral fiber boards, etc.). Any organic materials (i.e. plastics, wood paper products, etc.) are combustible and must not be used. The floor protection specified includes some form of thermal designation such as

Procedure:

1.Convert specifications to

i.

ii.

iii.

K x 12

iv.

2. Determine the

i. Use the formula in Step 1 to convert values not expressed as R.

ii. For multiple layers, add

3. If the overall

Rmineralboard = 0.291 x 0.125 = 0.431

Rtotal = Rbrick + Rmineralboard = 0.8 + 0.431 = 1.231

Step c: Compare proposed system Rtotal of 1.231 to specified R of 0.59. Since proposed system Rtotal is greater than required, the system is acceptable.

Definitions |

|

|

|

|

|

| |||

R = | (ft2)(hr)(°F) | k = | (Btu)(in) |

| = K x 12 | ||||

|

| Btu |

| (ft2)(hr)(°F) |

|

|

| ||

K = |

| (Btu)(ft) |

| r = | (ft2)(hr)(°F) | = | 1 |

| |

| (ft2)(hr)(°F) |

|

| (Btu)(in) |

|

| k |

| |

Floor Protection for Fireplace Installations

Do not assume that your fireplace hearth is completely noncombustible.

Many fireplace hearths do not meet the “completely noncombustible” requirement because the brick or concrete in front of the fireplace opening is supported by heavy wood framing. (Fig. 13) Because heat passes through brick or concrete readily, it can easily pass through to the wood. As a result, such fireplace hearths can be a fire hazard and are considered a combustible floor.

Keep in mind, also, that many raised hearths will extend less than the required clearance from the front of the heater when it is installed. In such cases, sufficient floor protection as described above must be added in front of the hearth to satisfy the minimum floor protector requirement from the front of the stove: 16” (406 mm) from the front in the United States and 18” (450 mm) from the front in Canada.

Hearth rugs do not satisfy the requirements for floor protection.

Fireplace installations also have special clearance requirements to the side walls, side decorative trim, and fireplace mantel. This information follows in the section

on Fireplace and Mantel Trim Shields.

10 | 30002425 |