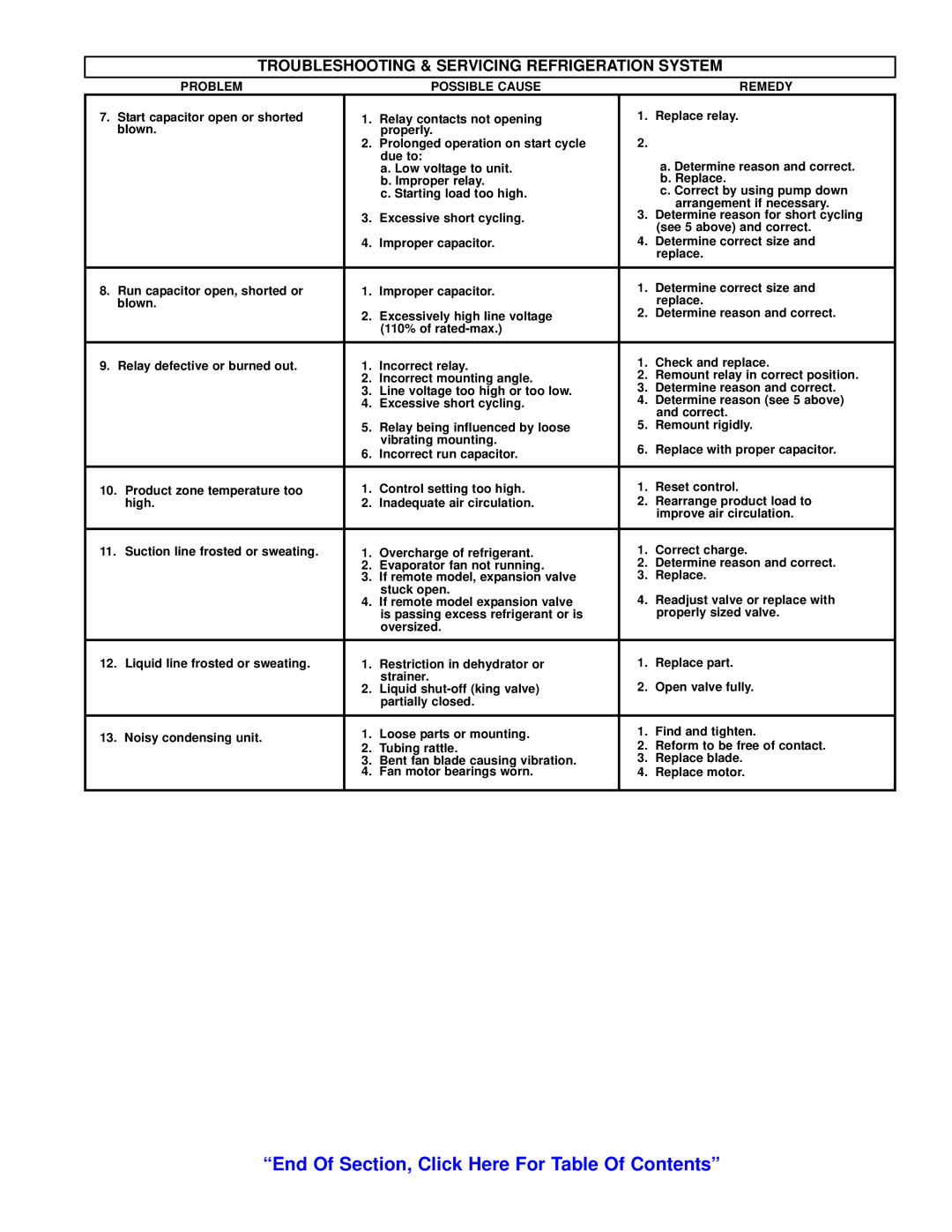

TROUBLESHOOTING & SERVICING REFRIGERATION SYSTEM

| PROBLEM |

| POSSIBLE CAUSE |

| REMEDY | |

7. | Start capacitor open or shorted | 1. | Relay contacts not opening | 1. | Replace relay. | |

| blown. |

| properly. | 2. |

| |

|

| 2. | Prolonged operation on start cycle |

| ||

|

|

| due to: |

| a. Determine reason and correct. | |

|

|

| a. Low voltage to unit. |

| ||

|

|

| b. Improper relay. |

| b. Replace. | |

|

|

| c. Starting load too high. |

| c. Correct by using pump down | |

|

|

|

|

| arrangement if necessary. | |

|

| 3. | Excessive short cycling. | 3. | Determine reason for short cycling | |

|

|

|

|

| (see 5 above) and correct. | |

|

| 4. | Improper capacitor. | 4. | Determine correct size and | |

|

|

|

|

| replace. | |

|

|

|

|

|

| |

8. | Run capacitor open, shorted or | 1. | Improper capacitor. | 1. | Determine correct size and | |

| blown. |

|

|

| replace. | |

|

| 2. | Excessively high line voltage | 2. | Determine reason and correct. | |

|

|

| (110% of |

|

| |

|

|

|

|

|

| |

9. | Relay defective or burned out. | 1. | Incorrect relay. | 1. | Check and replace. | |

|

| 2. | Incorrect mounting angle. | 2. | Remount relay in correct position. | |

|

| 3. | Line voltage too high or too low. | 3. | Determine reason and correct. | |

|

| 4. | Excessive short cycling. | 4. | Determine reason (see 5 above) | |

|

|

|

|

| and correct. | |

|

| 5. | Relay being influenced by loose | 5. | Remount rigidly. | |

|

|

| vibrating mounting. | 6. | Replace with proper capacitor. | |

|

| 6. | Incorrect run capacitor. | |||

|

|

|

| |||

|

|

|

|

|

| |

10. | Product zone temperature too | 1. | Control setting too high. | 1. | Reset control. | |

| high. | 2. | Inadequate air circulation. | 2. | Rearrange product load to | |

|

|

|

|

| improve air circulation. | |

|

|

|

|

| ||

11. Suction line frosted or sweating. | 1. | Overcharge of refrigerant. | 1. | Correct charge. | ||

|

| 2. | Evaporator fan not running. | 2. | Determine reason and correct. | |

|

| 3. | If remote model, expansion valve | 3. | Replace. | |

|

|

| stuck open. | 4. | Readjust valve or replace with | |

|

| 4. | If remote model expansion valve | |||

|

|

| is passing excess refrigerant or is |

| properly sized valve. | |

|

|

| oversized. |

|

| |

|

|

|

|

|

| |

12. | Liquid line frosted or sweating. | 1. | Restriction in dehydrator or | 1. | Replace part. | |

|

|

| strainer. | 2. | Open valve fully. | |

|

| 2. | Liquid | |||

|

|

| partially closed. |

|

| |

|

|

|

|

|

| |

13. | Noisy condensing unit. | 1. | Loose parts or mounting. | 1. | Find and tighten. | |

2. | Tubing rattle. | 2. | Reform to be free of contact. | |||

|

| |||||

|

| 3. | Bent fan blade causing vibration. | 3. | Replace blade. | |

|

| 4. | Fan motor bearings worn. | 4. | Replace motor. | |

|

|

|

|

|

| |