Appendix F

Concerning Conformal Coatings

LM104−P50−

JP1 |

| SERVICE |

| ||

JP2 |

| SET |

|

| RE |

|

|

| . | |

JP3 |

| TER |

| ||

| ||

|

|

|

|

|

|

|

|

| 1 | 2 |

| 3 | 4 |

| |

|

|

|

|

|

|

|

|

|

|

| |||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| JP4 |

|

|

|

|

|

|

1 | 2 |

| 3 | 4 | 5 | 6 | |||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

| JP5 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

R11P3

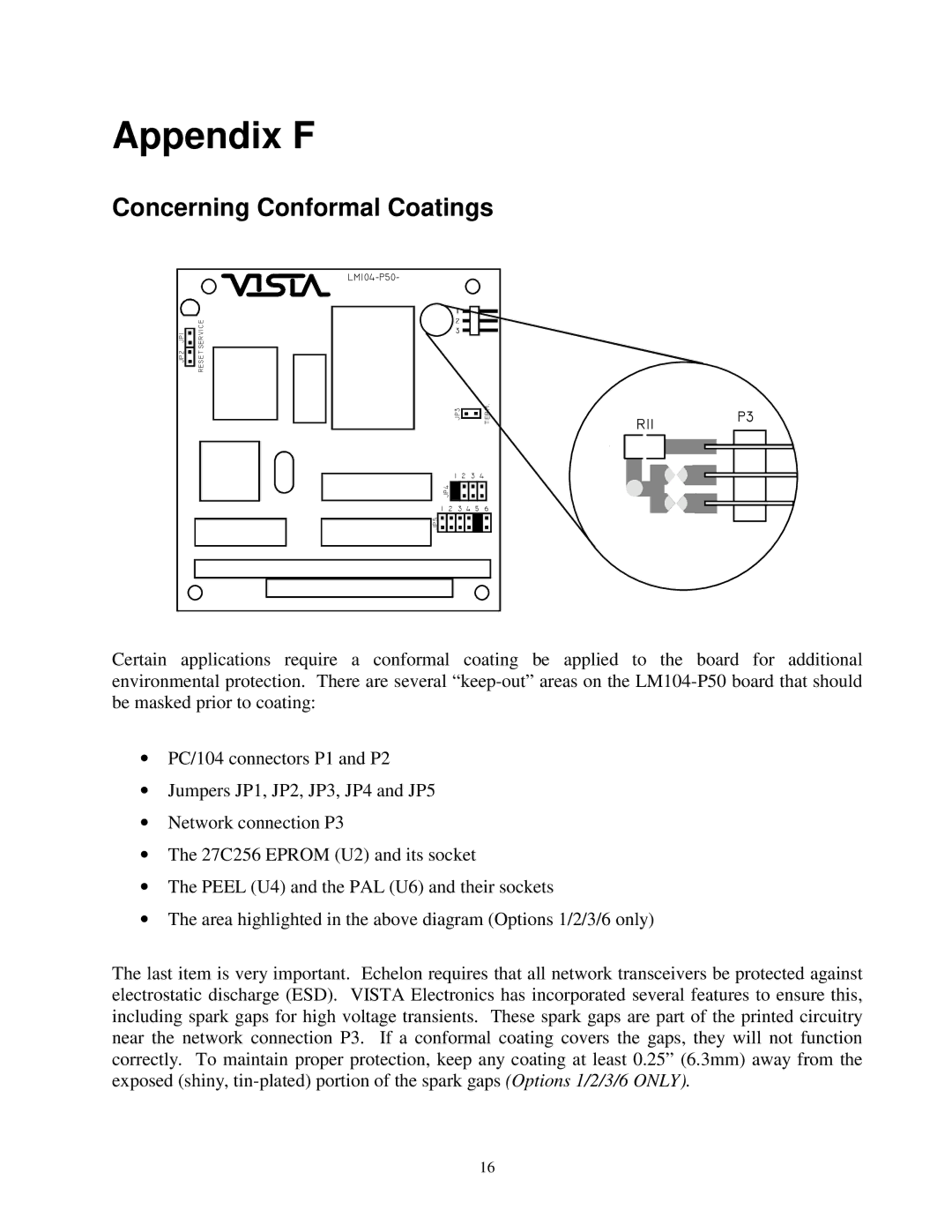

Certain applications require a conformal coating be applied to the board for additional environmental protection. There are several

•PC/104 connectors P1 and P2

•Jumpers JP1, JP2, JP3, JP4 and JP5

•Network connection P3

•The 27C256 EPROM (U2) and its socket

•The PEEL (U4) and the PAL (U6) and their sockets

•The area highlighted in the above diagram (Options 1/2/3/6 only)

The last item is very important. Echelon requires that all network transceivers be protected against electrostatic discharge (ESD). VISTA Electronics has incorporated several features to ensure this, including spark gaps for high voltage transients. These spark gaps are part of the printed circuitry near the network connection P3. If a conformal coating covers the gaps, they will not function correctly. To maintain proper protection, keep any coating at least 0.25” (6.3mm) away from the exposed (shiny,

16