Page 6 | WATERPIK TECHNOLOGIES INC. |

|

|

|

|

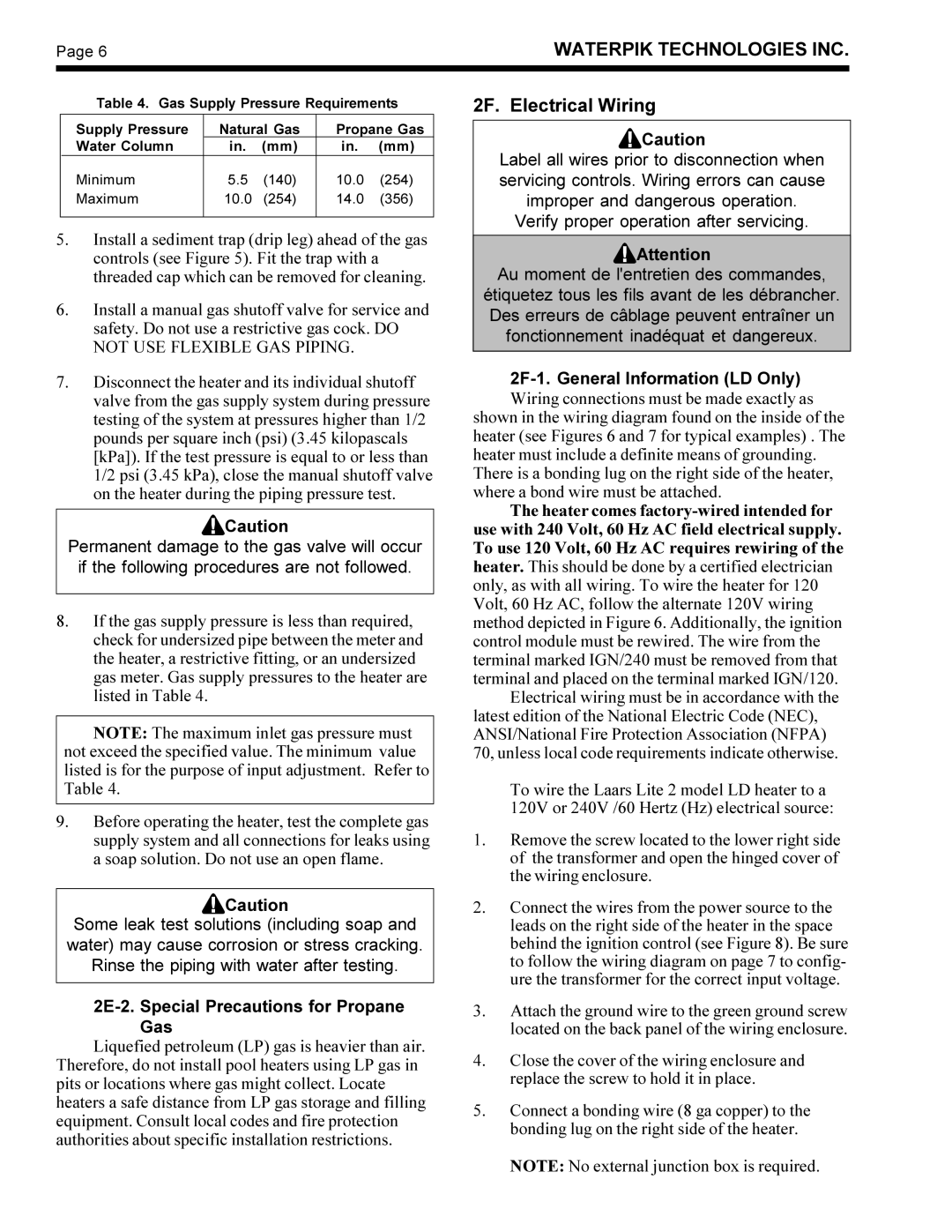

Table 4. Gas Supply Pressure Requirements

Supply Pressure | Natural Gas | Propane Gas | ||

Water Column | in. | (mm) | in. | (mm) |

Minimum | 5.5 | (140) | 10.0 | (254) |

Maximum | 10.0 | (254) | 14.0 | (356) |

|

|

|

|

|

5.Install a sediment trap (drip leg) ahead of the gas controls (see Figure 5). Fit the trap with a threaded cap which can be removed for cleaning.

6.Install a manual gas shutoff valve for service and safety. Do not use a restrictive gas cock. DO NOT USE FLEXIBLE GAS PIPING.

7.Disconnect the heater and its individual shutoff valve from the gas supply system during pressure testing of the system at pressures higher than 1/2 pounds per square inch (psi) (3.45 kilopascals [kPa]). If the test pressure is equal to or less than 1/2 psi (3.45 kPa), close the manual shutoff valve on the heater during the piping pressure test.

![]() Caution

Caution

Permanent damage to the gas valve will occur if the following procedures are not followed.

8.If the gas supply pressure is less than required, check for undersized pipe between the meter and the heater, a restrictive fitting, or an undersized gas meter. Gas supply pressures to the heater are listed in Table 4.

NOTE: The maximum inlet gas pressure must not exceed the specified value. The minimum value listed is for the purpose of input adjustment. Refer to Table 4.

9.Before operating the heater, test the complete gas supply system and all connections for leaks using a soap solution. Do not use an open flame.

![]()

![]() Caution

Caution

Some leak test solutions (including soap and water) may cause corrosion or stress cracking.

Rinse the piping with water after testing.

2E-2. Special Precautions for Propane Gas

Liquefied petroleum (LP) gas is heavier than air. Therefore, do not install pool heaters using LP gas in pits or locations where gas might collect. Locate heaters a safe distance from LP gas storage and filling equipment. Consult local codes and fire protection authorities about specific installation restrictions.

2F. Electrical Wiring

![]() Caution

Caution

Label all wires prior to disconnection when servicing controls. Wiring errors can cause improper and dangerous operation. Verify proper operation after servicing.

![]() Attention

Attention

Au moment de l'entretien des commandes, étiquetez tous les fils avant de les débrancher. Des erreurs de câblage peuvent entraîner un fonctionnement inadéquat et dangereux.

2F-1. General Information (LD Only)

Wiring connections must be made exactly as shown in the wiring diagram found on the inside of the heater (see Figures 6 and 7 for typical examples) . The heater must include a definite means of grounding. There is a bonding lug on the right side of the heater, where a bond wire must be attached.

The heater comes

Electrical wiring must be in accordance with the latest edition of the National Electric Code (NEC), ANSI/National Fire Protection Association (NFPA) 70, unless local code requirements indicate otherwise.

To wire the Laars Lite 2 model LD heater to a

120V or 240V /60 Hertz (Hz) electrical source:

1.Remove the screw located to the lower right side of the transformer and open the hinged cover of the wiring enclosure.

2.Connect the wires from the power source to the leads on the right side of the heater in the space behind the ignition control (see Figure 8). Be sure to follow the wiring diagram on page 7 to config- ure the transformer for the correct input voltage.

3.Attach the ground wire to the green ground screw located on the back panel of the wiring enclosure.

4.Close the cover of the wiring enclosure and replace the screw to hold it in place.

5.Connect a bonding wire (8 ga copper) to the bonding lug on the right side of the heater.

NOTE: No external junction box is required.