Spring |

|

Set screws |

|

| Approved |

Torsion shaft | winding rods |

| |

Winding cone |

|

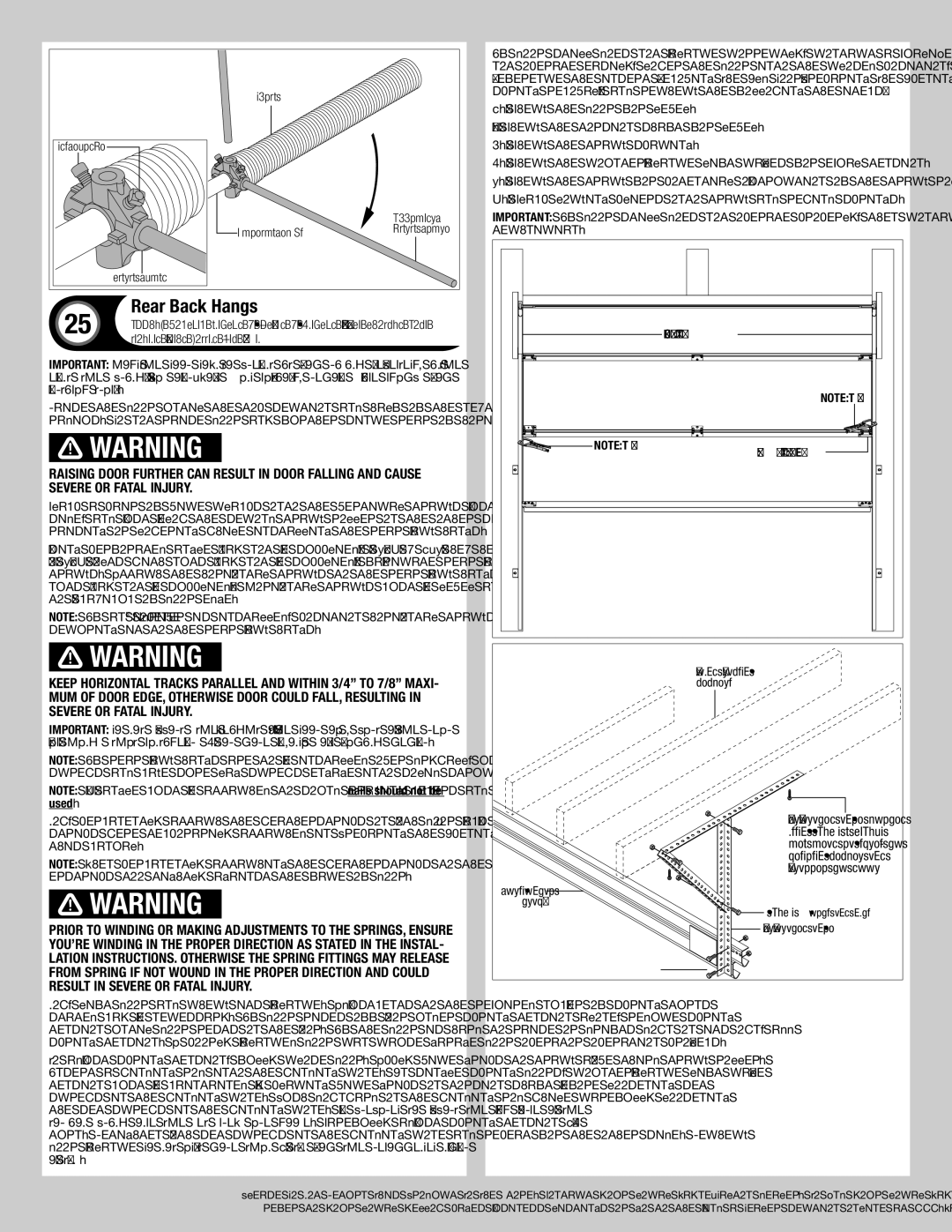

Rear Back Hangs

25 Tools: Ratchet wrench, 1/2” Socket, 1/2” Wrench, (2) Vice clamps, Tape measure, Level, Hammer, Step Ladder

Important: Hold the door down to prevent it from rising unexpectedly in the event the spring(s) was

Raise the door until the top section and half of the next section are in the horizontal track radius. Do not raise door any further since rear of horizontal tracks are not yet supported.

![]() WARNING

WARNING

Raising door further can result in door falling and cause severe or fatal injury.

Clamp a pair of vice clamps onto the vertical tracks just above the second track roller on one side, and just below the second track roller on the other side. This will prevent the door from raising or lowering while installing the rear back hangs.

Using perforated angle (may not be supplied), (2) 5/16” x

(3)5/16” bolts with nuts (may not be supplied), fabricate rear back hangs for the horizontal tracks. Attach the horizontal tracks to the rear back hangs with

NOTE: If an idrive® opener is installed, position horizontal tracks one hole above level when securing it to the rear back hangs.

![]() WARNING

WARNING

Keep horizontal tracks parallel and within 3/4” to 7/8” maxi- mum of door edge, otherwise door could fall, resulting in severe or fatal injury.

Important: Do not support the weight of the door on any part of the rear back hangs that cantilevers 4” or more beyond a sound framing member.

Note: If rear back hangs are to be installed over drywall, use (2) 5/16” x 2” hex head lag screws and make sure lag screws engage into solid structural lumber.

Note: 26” angle must be attached to sound framing members and nails should not be used.

If door still does not balance correctly, contact a qualified door agency. If the door still does not operate easily, lower the door into the closed position, UNWIND THE SPRING(S) FULLY (Reference the insert “Removing The Old Door/Preparing The Opening” section on torsion spring removal), and recheck the following the items:

1.) Check the door for level.

2.) Check the torsion shaft for level.

3.) Check the track spacing.

4.) Check the counterbalance lift cables for equal tension.

5.) Check the track for potential obstruction of the track rollers.

6.) Clamp locking pliers onto track and rewind springs.

IMPORTANT: If door still does not operate properly, then contact a trained door system technician.

| Horizontal tracks |

| Vice clamp |

Vice clamp | 2nd Track roller |

| |

| Sound framing |

| members |

Now, permanently attach the weatherstrips on both door jambs and header. The weather- strips were temporarily attached in Preparing the Opening, in the

NOTE: When permanently attaching the weatherstrips to the jambs, avoid pushing the weath- erstrips too tightly against the face of door.

![]() WARNING

WARNING

Prior to winding or making adjustments to the springs, ensure

Horizontal track

Perforated angle bolted using (2) 5/16” x

![]() (3) 5/16” Bolts and nuts

(3) 5/16” Bolts and nuts

Perforated angle

you’re winding in the proper direction as stated in the Instal- lation Instructions. Otherwise the spring fittings may release from spring if not wound in the proper direction and could result in severe or fatal injury.

Now, lift door and check its balance. Adjustments to the required number of spring turns stated may be necessary. If door rises off floor under spring tension alone, reduce spring tension until door rests on the floor. If the door is hard to raise or drifts down on its own, add spring tension. A poorly balanced door can cause garage door operator operation problems.

To adjust spring tension, fully close door. Apply vice grips to track above third track roller. Insert a winding rod into the winding cone. On single spring doors, counterbalance lift cable tension must be maintained by placing vice grips on torsion shaft before loosening set screws in the winding cone. Push downward on the winding rod while carefully loosening the set screws in the winding cone. BE PREPARED TO SUPPORT THE FULL FORCE OF THE TORSION SPRING ONCE THE SET SCREWS ARE LOOSE. Carefully adjust spring tension 1/4 turn. Retighten both set screws in the winding cone and repeat for the other side. Recheck door balance DO NOT ADJUST MORE THAN 1/2 TURN FROM THE RECOMMENDED NUMBER OF TURNS.

![]() track to serve as a roller stop

track to serve as a roller stop ![]()

![]()

![]()

13

Please Do Not Return This Product To The Store. Contact your local

refer to your local yellow pages business listings or go to the Find a Dealer section online at