| Center hinge |

| (3) 1/4” - 14 x 1” |

| Lag screws |

Typical | |

section | 2” Long strut |

shown. |

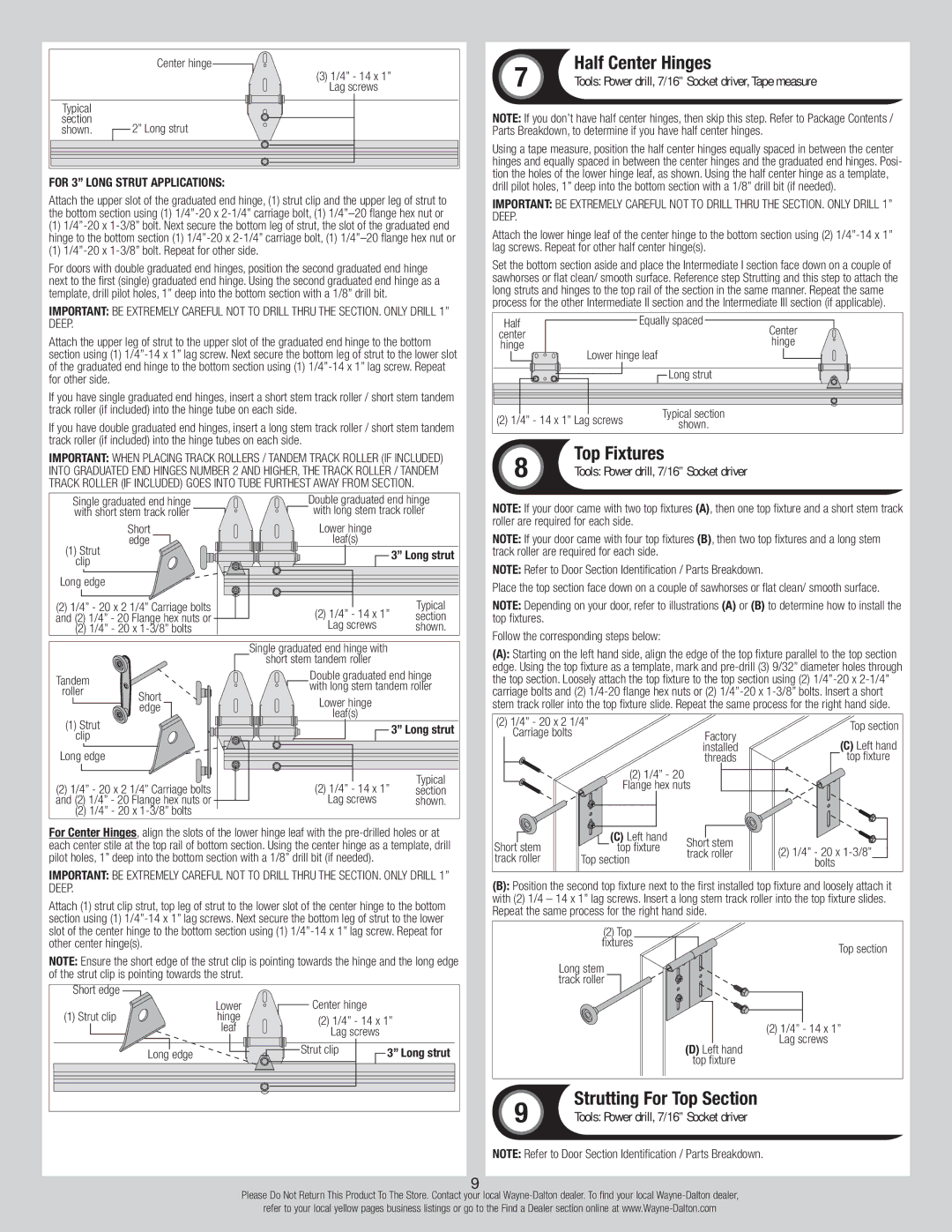

For 3” Long Strut Applications:

Attach the upper slot of the graduated end hinge, (1) strut clip and the upper leg of strut to the bottom section using (1) 1/4”-20 x 2-1/4” carriage bolt, (1) 1/4”–20 flange hex nut or

(1)1/4”-20 x 1-3/8” bolt. Next secure the bottom leg of strut, the slot of the graduated end hinge to the bottom section (1) 1/4”-20 x 2-1/4” carriage bolt, (1) 1/4”–20 flange hex nut or

(1)1/4”-20 x 1-3/8” bolt. Repeat for other side.

For doors with double graduated end hinges, position the second graduated end hinge next to the first (single) graduated end hinge. Using the second graduated end hinge as a template, drill pilot holes, 1” deep into the bottom section with a 1/8” drill bit.

IMPORTANT: Be extremely careful not to drill thru the section. Only drill 1” deep.

Attach the upper leg of strut to the upper slot of the graduated end hinge to the bottom section using (1) 1/4”-14 x 1” lag screw. Next secure the bottom leg of strut to the lower slot of the graduated end hinge to the bottom section using (1) 1/4”-14 x 1” lag screw. Repeat for other side.

If you have single graduated end hinges, insert a short stem track roller / short stem tandem track roller (if included) into the hinge tube on each side.

If you have double graduated end hinges, insert a long stem track roller / short stem tandem track roller (if included) into the hinge tubes on each side.

Important: When placing track rollers / tandem track roller (if included) into graduated end hinges number 2 and higher, the track roller / tandem track roller (if included) goes into tube furthest away from section.

| Single graduated end hinge | Double graduated end hinge |

| with short stem track roller | with long stem track roller |

| Short | Lower hinge |

| edge | leaf(s) |

| (1) Strut | 3” Long strut |

| clip |

| |

| Long edge | |

| (2) 1/4” - 20 x 2 1/4” Carriage bolts | (2) 1/4” - 14 x 1” | Typical |

| and (2) 1/4” - 20 Flange hex nuts or | section |

| (2) 1/4” - 20 x 1-3/8” bolts | Lag screws | shown. |

| | | Single graduated end hinge with | |

| | | short stem tandem roller | |

| Tandem | | Double graduated end hinge |

| | with long stem tandem roller |

| roller | Short |

| Lower hinge | |

| | edge | |

| | leaf(s) | |

| (1) Strut | | |

| | | 3” Long strut |

| clip | | |

| | | |

| Long edge | | | |

| (2) 1/4” - 20 x 2 1/4” Carriage bolts | (2) 1/4” - 14 x 1” | Typical |

| section |

| and (2) 1/4” - 20 Flange hex nuts or | Lag screws | shown. |

| (2) 1/4” - 20 x 1-3/8” bolts | | |

For Center Hinges, align the slots of the lower hinge leaf with the pre-drilled holes or at each center stile at the top rail of bottom section. Using the center hinge as a template, drill pilot holes, 1” deep into the bottom section with a 1/8” drill bit (if needed).

IMPORTANT: Be extremely careful not to drill thru the section. Only drill 1” deep.

Attach (1) strut clip strut, top leg of strut to the lower slot of the center hinge to the bottom section using (1) 1/4”-14 x 1” lag screws. Next secure the bottom leg of strut to the lower slot of the center hinge to the bottom section using (1) 1/4”-14 x 1” lag screw. Repeat for other center hinge(s).

NOTE: Ensure the short edge of the strut clip is pointing towards the hinge and the long edge of the strut clip is pointing towards the strut.

Short edge | | | |

(1) Strut clip | Lower | Center hinge | |

hinge | (2) 1/4” - 14 x 1” |

| leaf |

| Lag screws | |

| | |

| Long edge | Strut clip | 3” Long strut |

7 | Half Center Hinges |

Tools: Power drill, 7/16” Socket driver, Tape measure |

Note: If you don’t have half center hinges, then skip this step. Refer to Package Contents / Parts Breakdown, to determine if you have half center hinges.

Using a tape measure, position the half center hinges equally spaced in between the center hinges and equally spaced in between the center hinges and the graduated end hinges. Posi- tion the holes of the lower hinge leaf, as shown. Using the half center hinge as a template, drill pilot holes, 1” deep into the bottom section with a 1/8” drill bit (if needed).

IMPORTANT: Be extremely careful not to drill thru the section. Only drill 1” deep.

Attach the lower hinge leaf of the center hinge to the bottom section using (2) 1/4”-14 x 1” lag screws. Repeat for other half center hinge(s).

Set the bottom section aside and place the Intermediate I section face down on a couple of sawhorses or flat clean/ smooth surface. Reference step Strutting and this step to attach the long struts and hinges to the top rail of the section in the same manner. Repeat the same process for the other Intermediate II section and the Intermediate III section (if applicable).

| Half | | Equally spaced |

| center | | Center |

| | hinge |

| hinge | |

| Lower hinge leaf |

| |

| | | Long strut |

| (2) 1/4” - 14 x 1” Lag screws | Typical section |

| shown. |

| | |

| 8 | Top Fixtures |

| Tools: Power drill, 7/16” Socket driver |

NOTE: If your door came with two top fixtures (A), then one top fixture and a short stem track roller are required for each side.

NOTE: If your door came with four top fixtures (B), then two top fixtures and a long stem track roller are required for each side.

Note: Refer to Door Section Identification / Parts Breakdown.

Place the top section face down on a couple of sawhorses or flat clean/ smooth surface.

NOTE: Depending on your door, refer to illustrations (A) or (B) to determine how to install the top fixtures.

Follow the corresponding steps below:

(A): Starting on the left hand side, align the edge of the top fixture parallel to the top section edge. Using the top fixture as a template, mark and pre-drill (3) 9/32” diameter holes through the top section. Loosely attach the top fixture to the top section using (2) 1/4”-20 x 2-1/4” carriage bolts and (2) 1/4-20 flange hex nuts or (2) 1/4”-20 x 1-3/8” bolts. Insert a short stem track roller into the top fixture slide. Repeat the same process for the right hand side.

| (2) 1/4” - 20 x 2 1/4” | | Top section |

| Carriage bolts | | Factory |

| | (C) Left hand |

| | | installed |

| | | threads | top fixture |

| | (2) 1/4” - 20 | | |

| | Flange hex nuts | |

| | (C) Left hand | Short stem | |

| Short stem | top fixture | (2) 1/4” - 20 x 1-3/8” |

| track roller |

| track roller | Top section |

| | bolts |

(B): Position the second top fixture next to the first installed top fixture and loosely attach it with (2) 1/4 – 14 x 1” lag screws. Insert a long stem track roller into the top fixture slides. Repeat the same process for the right hand side.

(2) Top | |

fixtures | Top section |

|

Long stem | |

track roller | |

| (2) 1/4” - 14 x 1” |

| Lag screws |

| (D) Left hand |

| top fixture |

9 | Strutting For Top Section |

Tools: Power drill, 7/16” Socket driver |

Note: Refer to Door Section Identification / Parts Breakdown.