5 | Track Roller Carriers |

Tools: Power Drill, 9/32” Drill Bit, Socket Driver 7/16”, Wrench 7/16” |

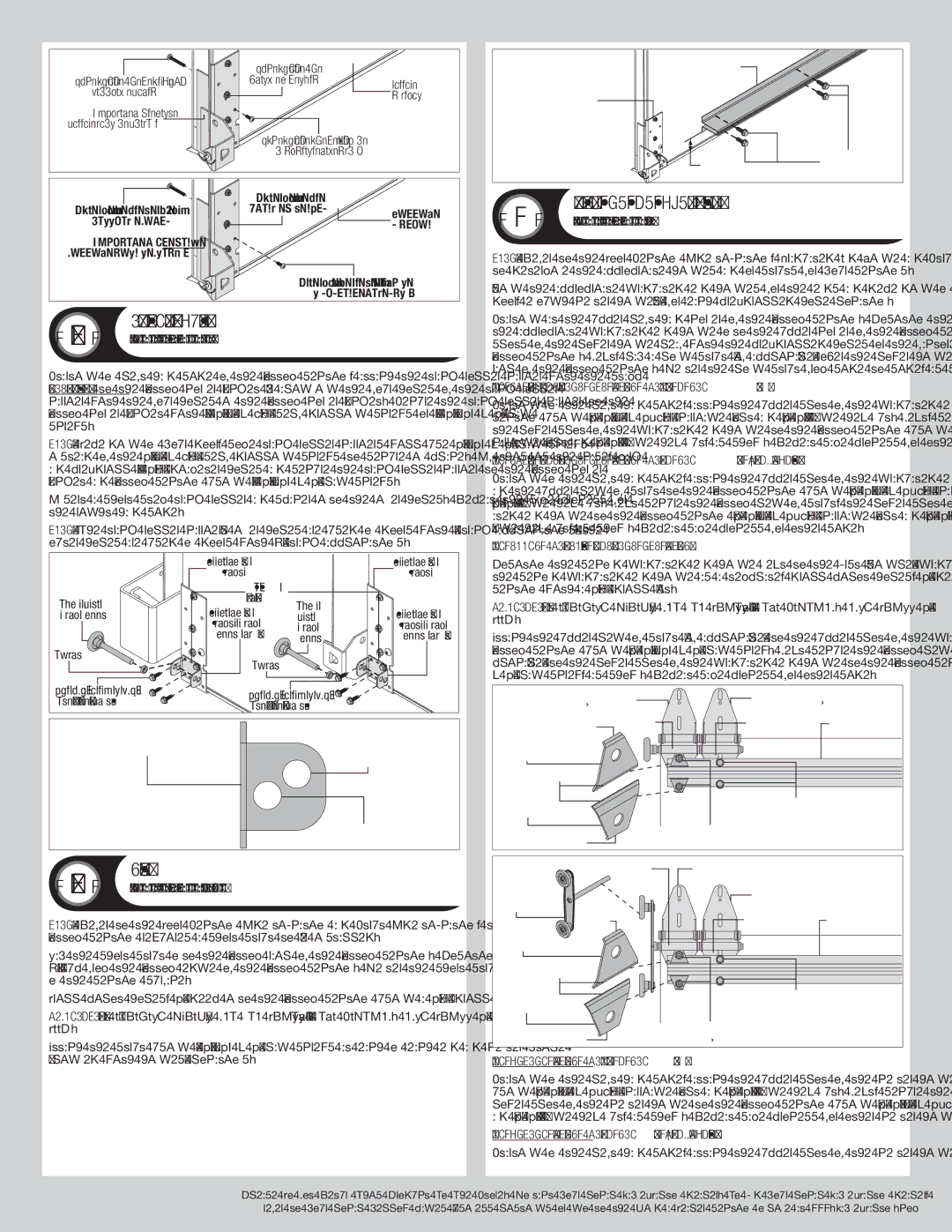

Starting on left hand side of the bottom section, attach the track roller carrier with the stamp “STD” facing UP to the bottom corner bracket by aligning the four holes of the track roller carrier with the four holes in the bottom corner bracket. Secure the track roller carrier to the bottom corner bracket with (4) 1/4”-20 x 7/8” self drilling screws or (4) 1/4”-14 x 1” lag screws.

NOTE: Depending on your door, some track roller carriers will use 1/4”-14 x 1” lag screws instead of the 1/4”-20 x 7/8” self drilling screws to secure in place. If this is the case, mark and pre-drill (4) 1/8” diameter holes and secure the track roller carrier to the bottom corner bracket and bottom section using (4) 1/4”-14 x 1” lag screws.

Insert a short stem track roller and spacer into the inner holes. Repeat the same process for the right hand side.

NOTE: The track roller carrier’s inner holes are used on doors with 2” track applications; the outer holes are used on doors with 3” track applications.

| Bottom corner | | Bottom corner |

| bracket | | bracket |

| “STD” | | |

Short stem | facing UP | Short | Bottom corner |

track roller | Bottom corner | stem |

| bracket track | track | bracket track |

| roller carrier | roller | roller carrier |

Spacer | Spacer | | |

| | |

(4) 1/4” - 20 x 7/8” | (4) 1/4” - 20 x 7/8” | |

Self drilling screws | |

Self drilling screws | |

| |

Side view of track roller

carrier(s)Outer holes (3” Track)

Inner holes

(2” Track)

6 Strutting

Tools: Power Drill, 1/8” Drill Bit, Socket Driver 7/16”, Tape Measure

NOTE: Refer to the Door Section Identification and Strut Identification, to determine if the bottom section requires a short strut to be installed.

Lay the short strut onto the bottom rail of the bottom section. Position the bottom of the strut 3/4” up from the bottom edge of the bottom section. Center the short strut from side to side on the section surface.

Drill pilot holes, 1” deep into the bottom section using a 1/8” drill bit.

IMPORTANT: Be extremely careful not to drill thru the section. Only drill 1” deep.

Attach the strut using (2) 1/4”-14 x 1” lag screws at each on each end and center stile (aligned with hinges) locations.

Starting at the upper left hand corner of the bottom section. Position the lower hinge leaf of the appropriate graduated end hinge onto the upper corner of the bottom section. Align the slots of the lower hinge leaf with the pre-drilled holes or the factory installed threads in the bottom section. Next, lay a long strut (if applicable) over the lower hinge leaf and over the top rail of the bottom section. Center the long strut from side to side, as shown.

For single graduated end hinges without a strut:

Starting on the left hand side, attach the upper slot of the graduated end hinge to the bottom section using (1) 1/4”-20 x 1-7/8” carriage bolt and (1) 1/4”–20 flange hex nut. Next, secure the lower slot of the graduated end hinge to the bottom section using (1) 1/4”-20 x 1-7/8” carriage bolt and (1) 1/4”–20 flange hex nut, as shown. Repeat same process for other side.

For single graduated end hinges with a strut (if applicable):

Starting on the left hand side, attach the upper slot of the graduated end hinge, (1) strut clip and the upper leg of strut to the bottom section using (1) 1/4”-20 x 1-7/8” carriage bolt and

(1)1/4”–20 flange hex nut. Next secure the bottom leg of strut, the lower slot of the gradu- ated end hinge to the bottom section (1) 1/4”-20 x 1-7/8” carriage bolt and (1) 1/4”–20 flange hex nut, as shown. Repeat same process for other side.

For doors with double graduated end hinges:

Position the second graduated end hinge next to the first (single) graduated end hinge. Using the second graduated end hinge as a template, drill pilot holes, 1” deep into the bottom section with a 1/8” drill bit.

IMPORTANT: Be extremely careful not to drill thru the section. Only drill 1” deep.

Attach the upper leg of strut (if applicable) to the upper slot of the graduated end hinge to the bottom section using (1) 1/4”-14 x 1” lag screw. Next secure the bottom leg of strut (if ap- plicable) to the lower slot of the graduated end hinge to the bottom section using (1) 1/4”-14 x 1” lag screw, as shown. Repeat same process for other side.

Single graduated end hinge | Double graduated end hinge |

with short stem track roller | with long stem track roller |

Short | Hinge | Lower hinge | | Long strut |

edge | tube(s) | leaf(s) | (if applicable) |

(1) Strut clip | | | | |

(if applicable) | | | | |

Long edge | | | | |

(1) Strut clip | | (2) 1/4” - 14 x 1” | Typical |

(if applicable) | | Lag screws | | section |

| | | | shown |

Short edge | | (2) 1/4” - 20 x 1 7/8” Carriage bolts | | |

| and (2) 1/4” - 20 Flange hex nuts | | |

| | Hinge | Single graduated end hinge with | |

| | tube(s) | short stem tandem roller | | |

Tandem | | | Double graduated end hinge |

| | with long stem tandem roller |

roller | | |

Short | | Lower hinge | | Long strut |

| | |

(1) Strut clip | edge | | leaf(s) | (if applicable) |

| | | | |

(if applicable) | | | | | |

Long edge | | | | | |

(1) Strut clip | | | (2) 1/4” - 14 x 1” | Typical |

(if applicable) | | | Lag screws | | section |

| | (2) 1/4” - 20 x 1 7/8” Carriage bolts | | shown |

Short edge | | | |

| and (2) 1/4” - 20 Flange hex nuts | | |

For Center Hinges without a strut:

Starting on the left hand side, attach the upper slot of the center hinge to the bottom section using (1) 1/4”-20 x 1-7/8” carriage bolt and (1) 1/4”–20 flange hex nut. Next, secure the lower slot of the center hinge to the bottom section using (1) 1/4”-20 x 1-7/8” carriage bolt and (1) 1/4”–20 flange hex nut, as shown. Repeat same process for other center hinges.

For Center Hinges with a strut (if applicable):

Starting on the left hand side, attach the upper slot of the center hinge, (1) strut clip and