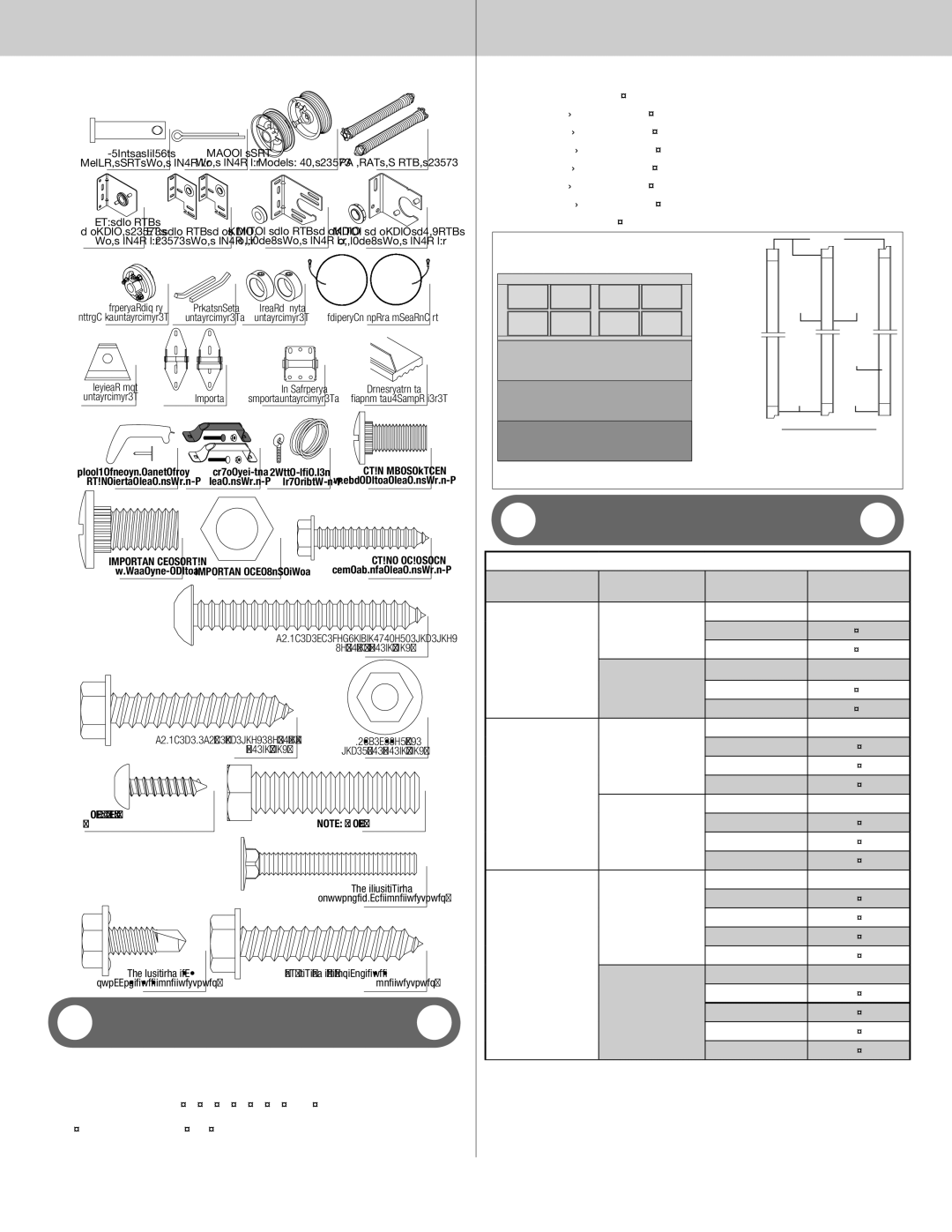

45, 42, 47, 40, 43 specifications

Wayne-Dalton is renowned for its innovative approach to garage doors, and the series 45, 43, 42, 47, and 40 exemplify their commitment to quality and performance. Each model is engineered with unique features that cater to both aesthetic preferences and functional requirements, ensuring homeowners find the perfect match for their needs.The Wayne-Dalton 45 model stands out with its distinctive design, offering a variety of panels and styles that can complement different architectural themes. This model utilizes durable materials such as steel and aluminum, providing excellent resistance against the elements while maintaining an attractive appearance. Its insulated version incorporates polyurethane foam, which effectively enhances energy efficiency, improving home comfort.

The 43 series is characterized by its robust construction and design flexibility. With multiple color options and textures, homeowners can easily personalize their garage doors. This model also highlights Wayne-Dalton’s innovative TorqueMaster® torsion spring system, which simplifies installation and enhances safety by keeping the spring contained within a steel tube.

The 42 model showcases a contemporary aesthetic, featuring sleek lines and modern designs that appeal to today’s homeowners. Constructed with high-quality materials, the 42 model offers excellent thermal insulation properties, reducing energy costs and increasing overall home efficiency. Its advanced weather sealing system prevents air and water infiltration, ensuring the interior remains comfortable regardless of external conditions.

The Wayne-Dalton 47 is designed for those seeking a more rustic or traditional look. This model mimics the appearance of wood with its faux-wood options while providing the durability of steel. Its insulation technology allows for significant energy savings, making it a sensible choice for regions with extreme weather conditions.

Lastly, the 40 model is recognized for its simplicity and reliability. It combines functionality with affordability, making it ideal for homeowners seeking an economical option without sacrificing quality. Its design allows for a smooth operation, and its long-lasting materials ensure that it withstands the test of time.

In summary, the Wayne-Dalton 45, 43, 42, 47, and 40 models showcase a variety of designs, technologies, and characteristics that cater to different homeowner preferences. From energy efficiency and security features to aesthetic choices, Wayne-Dalton continues to lead the market in garage door solutions. Whether prioritizing style, durability, or value, there is a Wayne-Dalton model that fits every homeowner's needs.