Step 3: Attach Unit to Front Wall Bracket

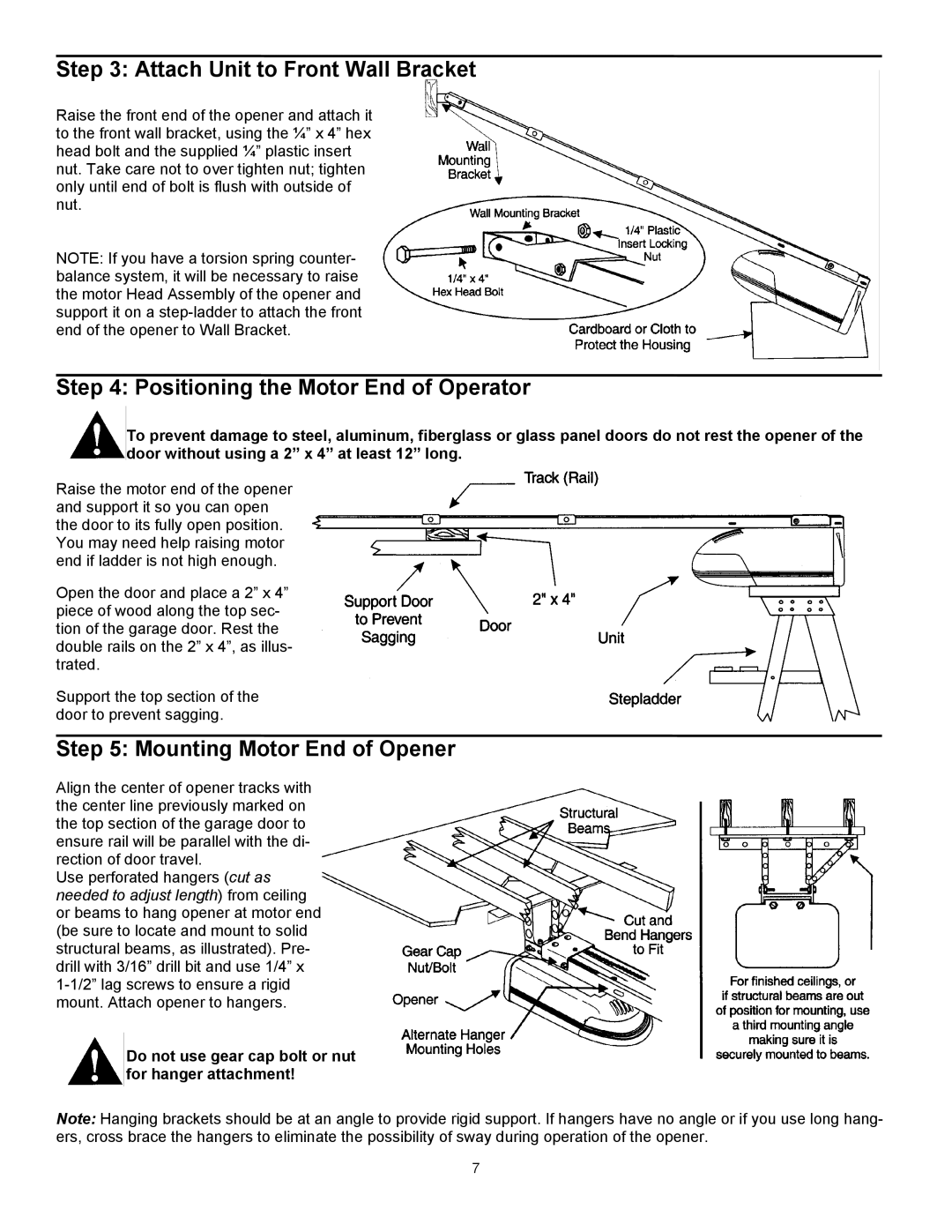

Raise the front end of the opener and attach it to the front wall bracket, using the ¼” x 4” hex head bolt and the supplied ¼” plastic insert nut. Take care not to over tighten nut; tighten only until end of bolt is flush with outside of nut.

NOTE: If you have a torsion spring counter- balance system, it will be necessary to raise the motor Head Assembly of the opener and support it on a

Step 4: Positioning the Motor End of Operator

To prevent damage to steel, aluminum, fiberglass or glass panel doors do not rest the opener of the door without using a 2” x 4” at least 12” long.

Raise the motor end of the opener and support it so you can open the door to its fully open position. You may need help raising motor end if ladder is not high enough.

Open the door and place a 2” x 4” piece of wood along the top sec- tion of the garage door. Rest the double rails on the 2” x 4”, as illus- trated.

Support the top section of the door to prevent sagging.

Step 5: Mounting Motor End of Opener

Align the center of opener tracks with the center line previously marked on the top section of the garage door to ensure rail will be parallel with the di- rection of door travel.

Use perforated hangers (cut as needed to adjust length) from ceiling or beams to hang opener at motor end (be sure to locate and mount to solid structural beams, as illustrated). Pre- drill with 3/16” drill bit and use 1/4” x

Do not use gear cap bolt or nut for hanger attachment!

Note: Hanging brackets should be at an angle to provide rigid support. If hangers have no angle or if you use long hang- ers, cross brace the hangers to eliminate the possibility of sway during operation of the opener.

7