Door Tests Before Starting

Before you begin, complete the following two tests to insure that the door is balanced and working properly. A door that binds, sticks or is out of balance could cause severe injury. Do not attempt to compensate for an improperly adjusted door by the installation of an opener. This will interfere with the proper operation of the opener mechanism and/or may damage the door. Have a qualified service person make any needed adjustments or repairs to cables, spring assemblies and other hardware before proceeding with installation.

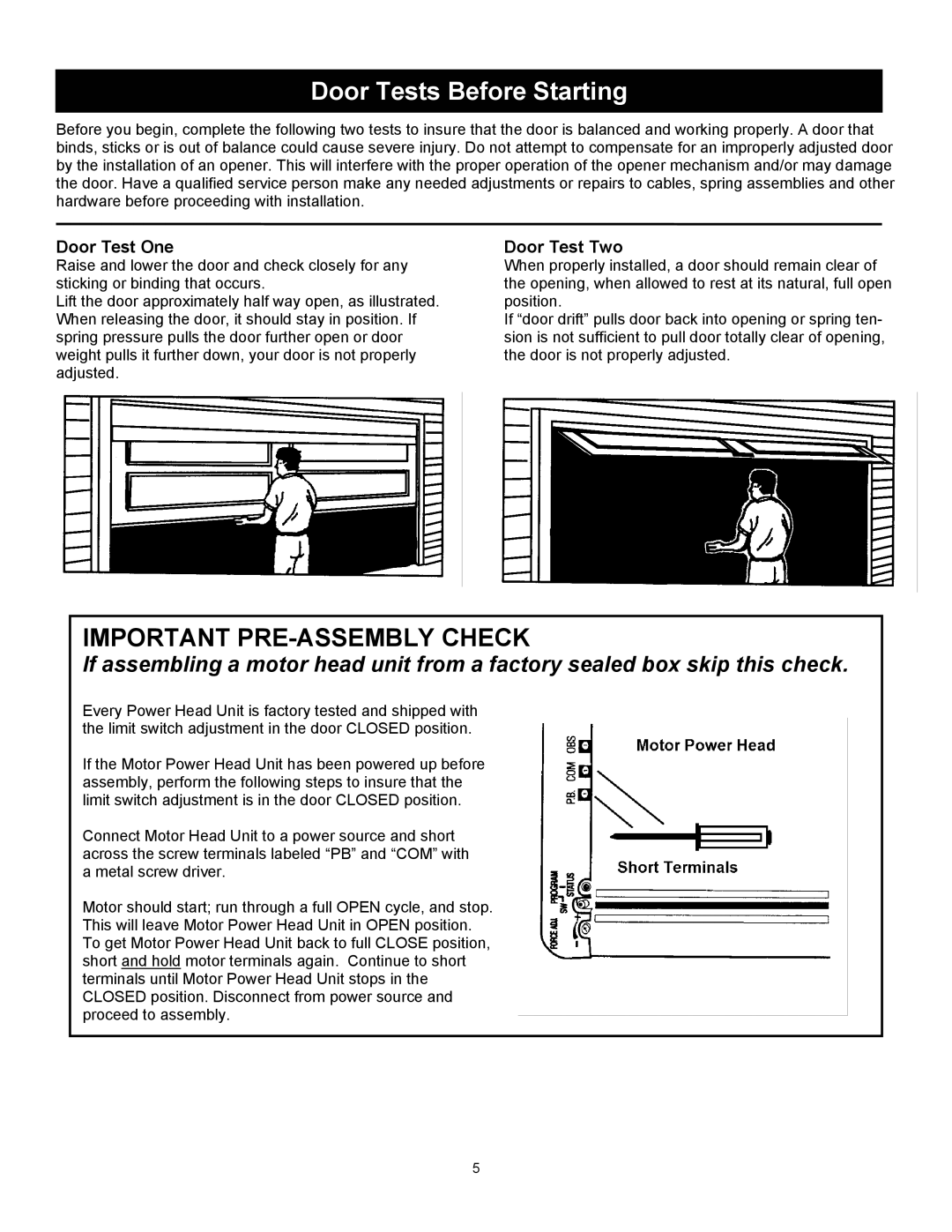

Door Test One

Raise and lower the door and check closely for any sticking or binding that occurs.

Lift the door approximately half way open, as illustrated. When releasing the door, it should stay in position. If spring pressure pulls the door further open or door weight pulls it further down, your door is not properly adjusted.

Door Test Two

When properly installed, a door should remain clear of the opening, when allowed to rest at its natural, full open position.

If “door drift” pulls door back into opening or spring ten- sion is not sufficient to pull door totally clear of opening, the door is not properly adjusted.

IMPORTANT PRE-ASSEMBLY CHECK

If assembling a motor head unit from a factory sealed box skip this check.

Every Power Head Unit is factory tested and shipped with the limit switch adjustment in the door CLOSED position.

If the Motor Power Head Unit has been powered up before assembly, perform the following steps to insure that the limit switch adjustment is in the door CLOSED position.

Connect Motor Head Unit to a power source and short across the screw terminals labeled “PB” and “COM” with a metal screw driver.

Motor should start; run through a full OPEN cycle, and stop. This will leave Motor Power Head Unit in OPEN position. To get Motor Power Head Unit back to full CLOSE position, short and hold motor terminals again. Continue to short terminals until Motor Power Head Unit stops in the CLOSED position. Disconnect from power source and proceed to assembly.

5