18

Part Number

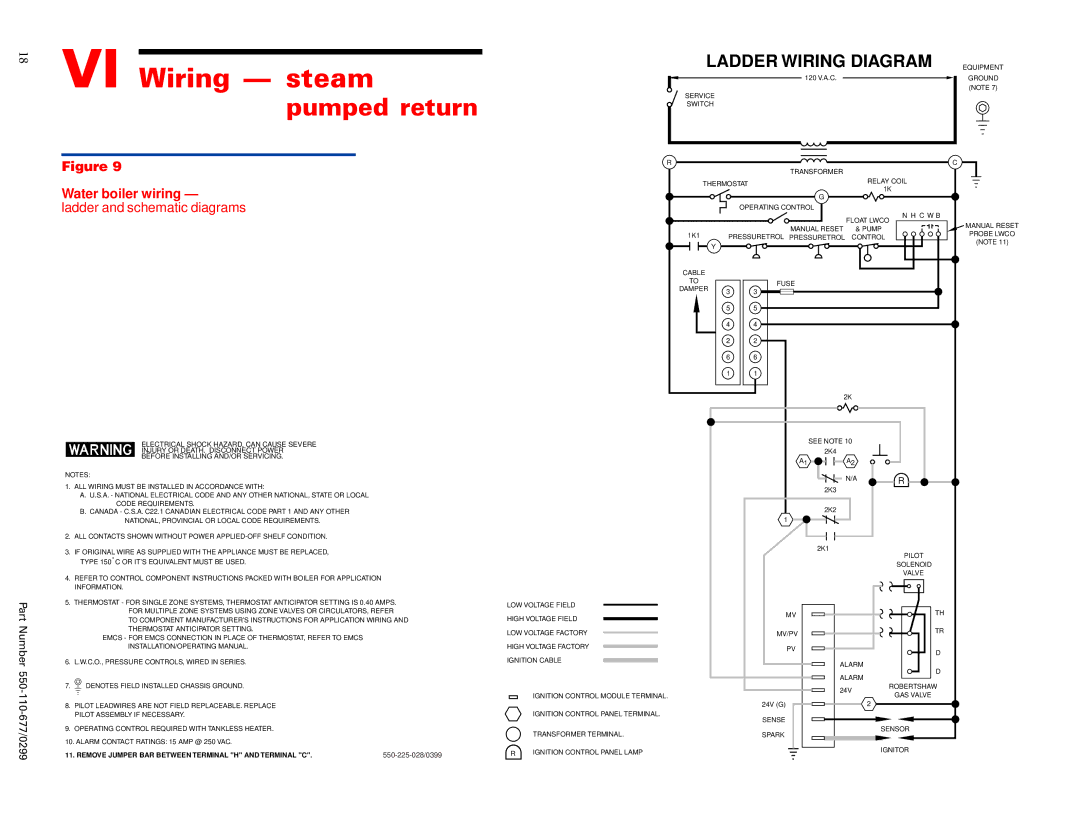

VI Wiring — steam |

|

| LADDER WIRING DIAGRAM | EQUIPMENT | ||||

|

| SERVICE |

| 120 V.A.C. |

|

| (NOTE 7) | |

pumped return |

|

|

|

|

| GROUND | ||

| SWITCH |

|

|

|

|

| ||

|

|

|

|

|

|

|

| |

Figure 9 |

|

| R |

|

|

|

| C |

|

|

|

| TRANSFORMER |

|

|

| |

|

|

| THERMOSTAT |

| RELAY COIL |

| ||

Water boiler wiring — |

|

|

| 1K |

| |||

|

|

|

|

|

|

| ||

|

|

|

| G |

|

|

| |

ladder and schematic diagrams |

|

|

|

| OPERATING CONTROL |

| N H C W B |

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

| FLOAT LWCO | MANUAL RESET | |

|

|

|

|

| MANUAL RESET | & PUMP | ||

|

|

| 1K1 |

| PROBE LWCO | |||

|

|

| PRESSURETROL PRESSURETROL | CONTROL | ||||

|

|

| Y |

|

|

|

| (NOTE 11) |

|

|

|

|

|

|

|

| |

|

|

| CABLE |

|

|

|

|

|

|

|

| TO |

| FUSE |

|

|

|

|

|

| DAMPER |

|

|

|

| |

|

|

| 3 | 3 |

|

|

| |

|

|

|

|

|

|

| ||

|

|

|

| 5 | 5 |

|

|

|

|

|

|

| 4 | 4 |

|

|

|

|

|

|

| 2 | 2 |

|

|

|

|

|

|

| 6 | 6 |

|

|

|

|

|

|

| 1 | 1 |

|

|

|

|

|

|

|

| 2K |

|

| |

ELECTRICAL SHOCK HAZARD, CAN CAUSE SEVERE |

|

|

|

| SEE NOTE 10 |

|

| |

|

|

|

|

|

|

|

| |

INJURY OR DEATH. DISCONNECT POWER |

|

|

|

| 2K4 |

|

|

|

BEFORE INSTALLING AND/OR SERVICING. |

|

|

|

| A1 | A2 |

|

|

|

|

|

|

|

|

| ||

NOTES: |

|

|

|

|

| N/A | R |

|

1. ALL WIRING MUST BE INSTALLED IN ACCORDANCE WITH: |

|

|

|

|

|

| ||

|

|

|

| 2K3 |

|

|

| |

A. U.S.A. - NATIONAL ELECTRICAL CODE AND ANY OTHER NATIONAL, STATE OR LOCAL |

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

| |

CODE REQUIREMENTS. |

|

|

|

| 2K2 |

|

|

|

B. CANADA - C.S.A. C22.1 CANADIAN ELECTRICAL CODE PART 1 AND ANY OTHER |

|

|

|

|

|

|

| |

NATIONAL, PROVINCIAL OR LOCAL CODE REQUIREMENTS. |

|

|

|

| 1 |

|

|

|

2. ALL CONTACTS SHOWN WITHOUT POWER |

|

|

|

|

|

|

|

|

3. IF ORIGINAL WIRE AS SUPPLIED WITH THE APPLIANCE MUST BE REPLACED, |

|

|

|

| 2K1 |

| PILOT |

|

|

|

|

|

|

|

| ||

o |

|

|

|

|

|

|

| |

TYPE 150 C OR IT’S EQUIVALENT MUST BE USED. |

|

|

|

|

|

| SOLENOID |

|

|

|

|

|

|

|

|

| |

4. REFER TO CONTROL COMPONENT INSTRUCTIONS PACKED WITH BOILER FOR APPLICATION |

|

|

|

|

|

| VALVE |

|

|

|

|

|

|

|

|

| |

INFORMATION. |

|

|

|

|

|

|

|

|

5. THERMOSTAT - FOR SINGLE ZONE SYSTEMS, THERMOSTAT ANTICIPATOR SETTING IS 0.40 AMPS. | LOW VOLTAGE FIELD |

|

|

|

|

| ||

FOR MULTIPLE ZONE SYSTEMS USING ZONE VALVES OR CIRCULATORS, REFER |

|

|

| TH |

| |||

HIGH VOLTAGE FIELD |

| MV |

|

| ||||

TO COMPONENT MANUFACTURER’S INSTRUCTIONS FOR APPLICATION WIRING AND |

|

|

|

| ||||

|

|

|

|

| ||||

THERMOSTAT ANTICIPATOR SETTING. |

| LOW VOLTAGE FACTORY |

| MV/PV |

| TR |

| |

EMCS - FOR EMCS CONNECTION IN PLACE OF THERMOSTAT, REFER TO EMCS |

|

|

|

| ||||

|

|

|

|

|

|

|

| |

INSTALLATION/OPERATING MANUAL. |

| HIGH VOLTAGE FACTORY |

| PV |

| D |

| |

|

|

|

|

|

|

| ||

|

| IGNITION CABLE |

|

|

|

| ||

6. L.W.C.O., PRESSURE CONTROLS, WIRED IN SERIES. |

|

| ALARM |

|

| |||

|

|

|

|

| D |

| ||

|

|

|

|

| ALARM |

| ||

|

|

|

|

|

|

| ||

7. DENOTES FIELD INSTALLED CHASSIS GROUND. |

|

|

|

| 24V | ROBERTSHAW |

| |

|

|

| IGNITION CONTROL MODULE TERMINAL. |

| GAS VALVE |

| ||

|

|

|

|

|

|

| ||

8. PILOT LEADWIRES ARE NOT FIELD REPLACEABLE. REPLACE |

|

|

|

| 24V (G) |

| 2 |

|

PILOT ASSEMBLY IF NECESSARY. |

|

| IGNITION CONTROL PANEL TERMINAL. |

| SENSE |

|

|

|

|

|

|

|

|

|

|

| |

9. OPERATING CONTROL REQUIRED WITH TANKLESS HEATER. |

|

| TRANSFORMER TERMINAL. |

| SPARK |

| SENSOR |

|

10. ALARM CONTACT RATINGS: 15 AMP @ 250 VAC. |

|

|

|

|

|

| ||

|

|

|

|

|

|

|

| |

11. REMOVE JUMPER BAR BETWEEN TERMINAL "H" AND TERMINAL "C". | R | IGNITION CONTROL PANEL LAMP |

|

|

| IGNITOR |

| |

|

|

|

|

| ||||