14

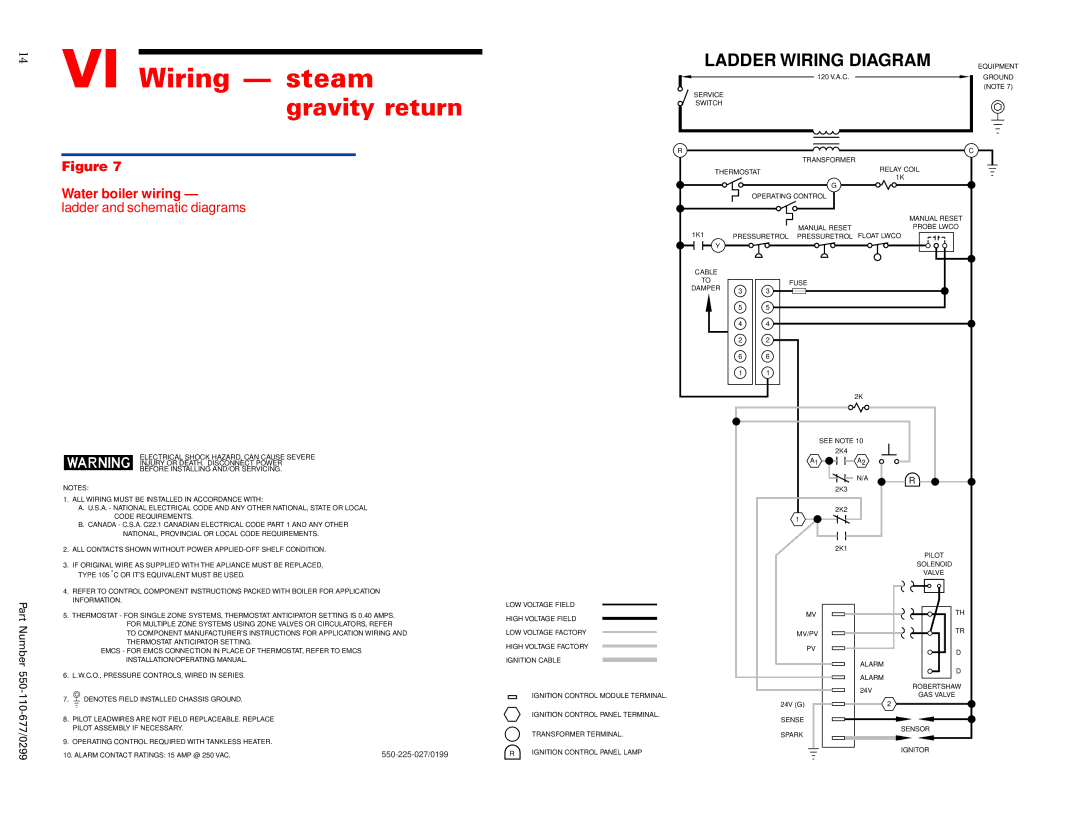

VI Wiring — steam | LADDER WIRING DIAGRAM | EQUIPMENT | |

SERVICE | 120 V.A.C. | (NOTE 7) | |

gravity return |

| GROUND | |

SWITCH |

|

| |

|

|

| |

| R |

| C |

Figure 7 |

| TRANSFORMER |

|

THERMOSTAT | RELAY COIL |

| |

|

| 1K |

|

|

| G |

|

Water boiler wiring — |

| OPERATING CONTROL |

|

|

ladder and schematic diagrams |

|

|

| MANUAL RESET |

|

|

|

| |

1K1 |

| MANUAL RESET |

| PROBE LWCO |

PRESSURETROL PRESSURETROL FLOAT LWCO |

| |||

Y |

|

|

|

|

CABLE |

|

|

|

|

TO |

| FUSE |

|

|

DAMPER |

|

|

| |

3 | 3 |

|

| |

|

|

| ||

| 5 | 5 |

|

|

| 4 | 4 |

|

|

| 2 | 2 |

|

|

| 6 | 6 |

|

|

| 1 | 1 |

|

|

|

|

| 2K |

|

|

| SEE NOTE 10 |

| |

ELECTRICAL SHOCK HAZARD, CAN CAUSE SEVERE |

| 2K4 |

|

|

| A1 | A2 |

| |

INJURY OR DEATH. DISCONNECT POWER |

|

| ||

BEFORE INSTALLING AND/OR SERVICING. |

|

|

|

|

NOTES: |

|

| N/A | R |

| 2K3 |

|

| |

1. ALL WIRING MUST BE INSTALLED IN ACCORDANCE WITH: |

|

|

|

|

A. U.S.A. - NATIONAL ELECTRICAL CODE AND ANY OTHER NATIONAL, STATE OR LOCAL |

| 2K2 |

|

|

CODE REQUIREMENTS. |

| 1 |

|

|

B. CANADA - C.S.A. C22.1 CANADIAN ELECTRICAL CODE PART 1 AND ANY OTHER

NATIONAL, PROVINCIAL OR LOCAL CODE REQUIREMENTS.

Part Number

2.ALL CONTACTS SHOWN WITHOUT POWER

3.IF ORIGINAL WIRE AS SUPPLIED WITH THE APLIANCE MUST BE REPLACED,

o

TYPE 105 C OR IT’S EQUIVALENT MUST BE USED.

4.REFER TO CONTROL COMPONENT INSTRUCTIONS PACKED WITH BOILER FOR APPLICATION INFORMATION.

5.THERMOSTAT - FOR SINGLE ZONE SYSTEMS, THERMOSTAT ANTICIPATOR SETTING IS 0.40 AMPS. FOR MULTIPLE ZONE SYSTEMS USING ZONE VALVES OR CIRCULATORS, REFER

TO COMPONENT MANUFACTURER’S INSTRUCTIONS FOR APPLICATION WIRING AND THERMOSTAT ANTICIPATOR SETTING.

EMCS - FOR EMCS CONNECTION IN PLACE OF THERMOSTAT, REFER TO EMCS INSTALLATION/OPERATING MANUAL.

6.L.W.C.O., PRESSURE CONTROLS, WIRED IN SERIES.

7.![]() DENOTES FIELD INSTALLED CHASSIS GROUND.

DENOTES FIELD INSTALLED CHASSIS GROUND.

8.PILOT LEADWIRES ARE NOT FIELD REPLACEABLE. REPLACE PILOT ASSEMBLY IF NECESSARY.

9.OPERATING CONTROL REQUIRED WITH TANKLESS HEATER.

10. ALARM CONTACT RATINGS: 15 AMP @ 250 VAC. |

|

|

|

| 2K1 | ||

LOW VOLTAGE FIELD |

| MV |

|

|

|

|

|

|

| ||

|

|

|

| ||

HIGH VOLTAGE FIELD |

|

|

|

| |

|

|

|

| ||

|

|

| |||

|

|

|

|

| |

LOW VOLTAGE FACTORY |

| MV/PV |

|

|

|

|

|

|

| ||

HIGH VOLTAGE FACTORY |

| PV |

|

|

|

IGNITION CABLE |

|

|

|

| ALARM |

|

|

|

| ||

|

|

|

|

| |

|

|

|

|

| |

|

|

|

|

| ALARM |

|

|

|

|

| |

|

|

|

|

| |

|

|

|

|

| 24V |

|

|

|

|

| |

| IGNITION CONTROL MODULE TERMINAL. |

|

|

|

|

|

|

|

|

|

| IGNITION CONTROL PANEL TERMINAL. | 24V (G) |

|

|

| 2 | ||||

|

|

|

| |||||||

| SENSE |

|

|

|

| |||||

| TRANSFORMER TERMINAL. |

|

|

|

| |||||

|

|

|

|

| ||||||

| SPARK |

|

|

|

| |||||

|

|

|

|

| ||||||

R | IGNITION CONTROL PANEL LAMP |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

| ||

PILOT

SOLENOID

VALVE

TH

TR

D

D

ROBERTSHAW GAS VALVE

SENSOR

IGNITOR